| Availability: | |

|---|---|

| Quantity: | |

Product Introduction

Injection molding machine is a commonly used plastic processing equipment, mainly used for producing hollow products such as plastic bottles and containers. This article will provide a professional introduction to injection blown machines from three aspects: working principle, equipment composition, and application fields.

Firstly, the working principle of the injection molding machine is to inject pre heated and melted plastic particles into the mold. Through the closure of the mold and the action of air pressure, the plastic particles are fully fused and attached to the inner wall of the mold, forming a hollow bottle embryo. Subsequently, high-pressure air is injected into the preform through a blowing system, causing it to expand into the desired shape and solidify during the cooling process. Finally, open the mold and take out the finished product.

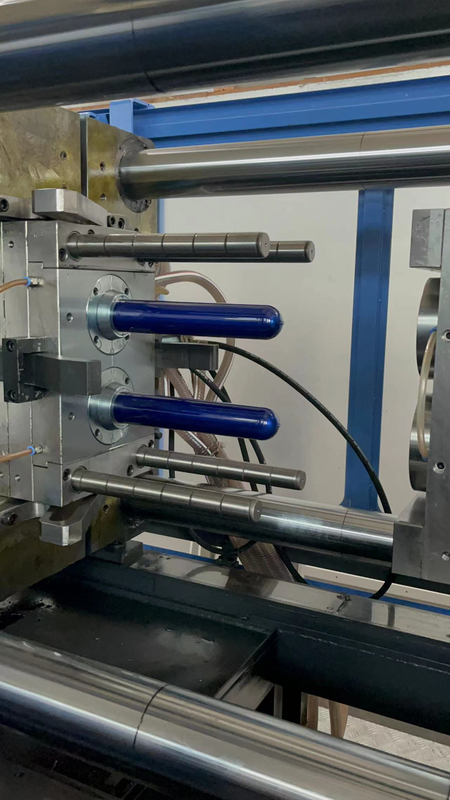

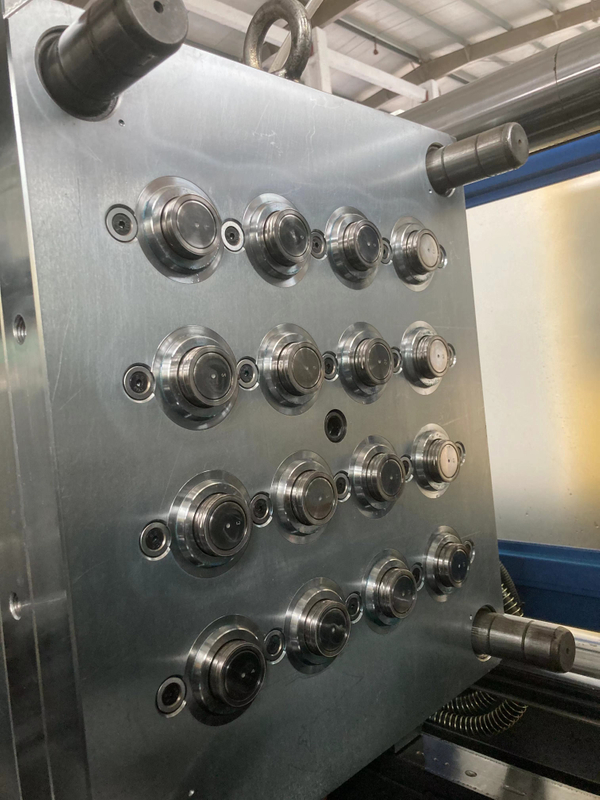

The injection blow machine mainly consists of an injection device, a blowing device, a mold, and a control system. In the injection device, plastic particles are heated and melted before being injected into the mold through the movement of screws. The shape of the cavity in the mold corresponds to the desired product. By closing the mold, molten plastic is injected into the mold and solidified during the cooling process. The blowing device injects high-pressure air into the preform through a nozzle, causing it to expand into a hollow product. The control system is used to control the operation and parameter adjustment of the entire injection and blowing machine.

Injection blown machines have a wide range of applications in industrial production. Firstly, it can produce hollow products such as plastic bottles and containers of various shapes and specifications, such as beverage bottles, cosmetic bottles, shampoo bottles, etc. Secondly, injection blown machines have the characteristics of high efficiency and speed, which can meet the needs of large-scale production. In addition, the injection blowing machine has a high degree of automation and easy operation, which can improve production efficiency and product quality. Injection blown machines can also produce products of different shapes and specifications by changing molds and adjusting process parameters, with high flexibility and adaptability.

In summary, a blow molding machine is a commonly used plastic processing equipment that injects pre heated and melted plastic particles into a mold, forms a hollow bottle preform through the closure of the mold and the action of air pressure, and expands it into the desired shape through a blowing device. It has the characteristics of high efficiency, speed, and flexibility, and is widely used in the production of hollow products such as plastic bottles and containers. With the continuous progress of technology, injection blown machine technology will further develop and improve, providing more possibilities for production in various industries.

Technical Parameter

ITEM | UNIT | SZ—1300A | ||

INJECTION UNIT | ||||

SCREW DIAMETER | mm | 35 | 40 | 45 |

SCREW LID RATIO | L/D | 24 | 21 | 18.7 |

THEORETICAL SHOT VOLUME | CM3 | 173 | 226 | 286 |

SHOT WEIGHT(PS) | g | 158 | 206 | 260 |

INJECTION PRESSURE | Mpa | 235 | 180 | 142 |

THEORETICAL INJECTION RATE(PS) | g/s | 110 | 143 | 181 |

PLASTICISING CAPACITY | g/s | 13.8 | 19.7 | 27.1 |

SCREW TORQUE | N.m | 740 | ||

MAX.SCREW ROTATE SPEED | r/min | 250 | ||

INJECTION STROKE | mm | 180 | ||

CLAMPING UNIT | ||||

MAX.CLAMPING FORCE K | KN | 1300 | ||

MAX.OPENING STROKE | mm | 400 | ||

SPACE BETWEEN TIE BARS | mm | 420×420 | ||

MOULD HEIGHT | mm | 160-440 | ||

MAX.DAYLIGHT | mm | 840 | ||

EJECTOR FORCE | KN | 31.4 | ||

EJECTOR STROKE | mm | 100 | ||

EJECTOR QUANTITY | 5 | |||

OTHER | ||||

PUMP MOTOR POWER | KW | 13 | ||

PUMP PRESSURE | Mpa | 16 | ||

HEATING POWER | KW | 9.2 | ||

HEATING ZONE | 4 | |||

SIZE | m | 4.7×1.25×1.85 | ||

NET WEIGHT | t | 4.3 | ||

OIL TANK CAPACITY | L | 360 | ||

INTERNATIONAL DESIGNATION | 1300—410 | |||

SZ series Injection Molding Machine will offer you the best performance, safety and reliability. This machine applies 5-point double toggle links clamping system featured reliable, energy-saving, high-speed, stable, long closing stroke and big clamping force.

Hydraulic motor drives the mould adjustment device with the advantage of rapid and light. This machine is equipped with one line type screw. The hydraulic motor with low speed and big torque can directly drive plasticizing, double cylinder type injection system, with the feature of processing many kinds of material, strong plasticizing ability and fine injection effect. Three optional screws are supplied for every model to meet the various requirements of customers.

The barrel is heated by resistance heating rings. The temperatures are controlled by automatic Temperature Controller or the PAD system in computer with the feature of quick, stable and even. This machine offers electrical and mechanical safety interlock at least. And the bigger or superior machine also provide hydraulic safety interlock to assure safe and reliable.

Our Company

OUr company founded in 1999, the company is a solid factory with 23 years of production and manufacturing of injection molding machines. Very experienced. The company has superior geographical location, close to the port city, convenient transportation and fast transportation.

It has export experience in more than 60 countries and regions around the world. Able to dispatch engineers for export commissioning and maintenance. One-year remote warranty service, 24 sales online remote solution for you.

The company won the ISO9001 quality management system certificate issued by TUV in Germany and the CE certificate issued by IG in Italy.

Product Introduction

Injection molding machine is a commonly used plastic processing equipment, mainly used for producing hollow products such as plastic bottles and containers. This article will provide a professional introduction to injection blown machines from three aspects: working principle, equipment composition, and application fields.

Firstly, the working principle of the injection molding machine is to inject pre heated and melted plastic particles into the mold. Through the closure of the mold and the action of air pressure, the plastic particles are fully fused and attached to the inner wall of the mold, forming a hollow bottle embryo. Subsequently, high-pressure air is injected into the preform through a blowing system, causing it to expand into the desired shape and solidify during the cooling process. Finally, open the mold and take out the finished product.

The injection blow machine mainly consists of an injection device, a blowing device, a mold, and a control system. In the injection device, plastic particles are heated and melted before being injected into the mold through the movement of screws. The shape of the cavity in the mold corresponds to the desired product. By closing the mold, molten plastic is injected into the mold and solidified during the cooling process. The blowing device injects high-pressure air into the preform through a nozzle, causing it to expand into a hollow product. The control system is used to control the operation and parameter adjustment of the entire injection and blowing machine.

Injection blown machines have a wide range of applications in industrial production. Firstly, it can produce hollow products such as plastic bottles and containers of various shapes and specifications, such as beverage bottles, cosmetic bottles, shampoo bottles, etc. Secondly, injection blown machines have the characteristics of high efficiency and speed, which can meet the needs of large-scale production. In addition, the injection blowing machine has a high degree of automation and easy operation, which can improve production efficiency and product quality. Injection blown machines can also produce products of different shapes and specifications by changing molds and adjusting process parameters, with high flexibility and adaptability.

In summary, a blow molding machine is a commonly used plastic processing equipment that injects pre heated and melted plastic particles into a mold, forms a hollow bottle preform through the closure of the mold and the action of air pressure, and expands it into the desired shape through a blowing device. It has the characteristics of high efficiency, speed, and flexibility, and is widely used in the production of hollow products such as plastic bottles and containers. With the continuous progress of technology, injection blown machine technology will further develop and improve, providing more possibilities for production in various industries.

Technical Parameter

ITEM | UNIT | SZ—1300A | ||

INJECTION UNIT | ||||

SCREW DIAMETER | mm | 35 | 40 | 45 |

SCREW LID RATIO | L/D | 24 | 21 | 18.7 |

THEORETICAL SHOT VOLUME | CM3 | 173 | 226 | 286 |

SHOT WEIGHT(PS) | g | 158 | 206 | 260 |

INJECTION PRESSURE | Mpa | 235 | 180 | 142 |

THEORETICAL INJECTION RATE(PS) | g/s | 110 | 143 | 181 |

PLASTICISING CAPACITY | g/s | 13.8 | 19.7 | 27.1 |

SCREW TORQUE | N.m | 740 | ||

MAX.SCREW ROTATE SPEED | r/min | 250 | ||

INJECTION STROKE | mm | 180 | ||

CLAMPING UNIT | ||||

MAX.CLAMPING FORCE K | KN | 1300 | ||

MAX.OPENING STROKE | mm | 400 | ||

SPACE BETWEEN TIE BARS | mm | 420×420 | ||

MOULD HEIGHT | mm | 160-440 | ||

MAX.DAYLIGHT | mm | 840 | ||

EJECTOR FORCE | KN | 31.4 | ||

EJECTOR STROKE | mm | 100 | ||

EJECTOR QUANTITY | 5 | |||

OTHER | ||||

PUMP MOTOR POWER | KW | 13 | ||

PUMP PRESSURE | Mpa | 16 | ||

HEATING POWER | KW | 9.2 | ||

HEATING ZONE | 4 | |||

SIZE | m | 4.7×1.25×1.85 | ||

NET WEIGHT | t | 4.3 | ||

OIL TANK CAPACITY | L | 360 | ||

INTERNATIONAL DESIGNATION | 1300—410 | |||

SZ series Injection Molding Machine will offer you the best performance, safety and reliability. This machine applies 5-point double toggle links clamping system featured reliable, energy-saving, high-speed, stable, long closing stroke and big clamping force.

Hydraulic motor drives the mould adjustment device with the advantage of rapid and light. This machine is equipped with one line type screw. The hydraulic motor with low speed and big torque can directly drive plasticizing, double cylinder type injection system, with the feature of processing many kinds of material, strong plasticizing ability and fine injection effect. Three optional screws are supplied for every model to meet the various requirements of customers.

The barrel is heated by resistance heating rings. The temperatures are controlled by automatic Temperature Controller or the PAD system in computer with the feature of quick, stable and even. This machine offers electrical and mechanical safety interlock at least. And the bigger or superior machine also provide hydraulic safety interlock to assure safe and reliable.

Our Company

OUr company founded in 1999, the company is a solid factory with 23 years of production and manufacturing of injection molding machines. Very experienced. The company has superior geographical location, close to the port city, convenient transportation and fast transportation.

It has export experience in more than 60 countries and regions around the world. Able to dispatch engineers for export commissioning and maintenance. One-year remote warranty service, 24 sales online remote solution for you.

The company won the ISO9001 quality management system certificate issued by TUV in Germany and the CE certificate issued by IG in Italy.