ZHANG JIA GANG SHEN ZHOU MACHINERY CO.,LTD.located in Zhangjiagang —new Port City of China, we are closed to shanghai and have great convenience on transportation.

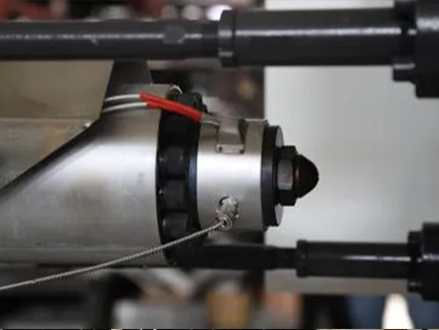

We are a physical factory established in 1999 and have 25 years of experience in injection molding machine manufacturing.

We gather many years of rich experience to make “SZ” series automatic computer Injection Molding Machine and its equipment. Its excellent quality, stable performance, attractive price-performance meet the client's demands and profits.