Custom plastic injection molding is a unique process for manufacturing plastic items in various shapes and sizes. It’s a neat way to make toys, tools and all sorts of other stuff. Do you ever wonder how your favorite toy or even your toothbrush came to be? It could have been produced through custom plastic injection molding.

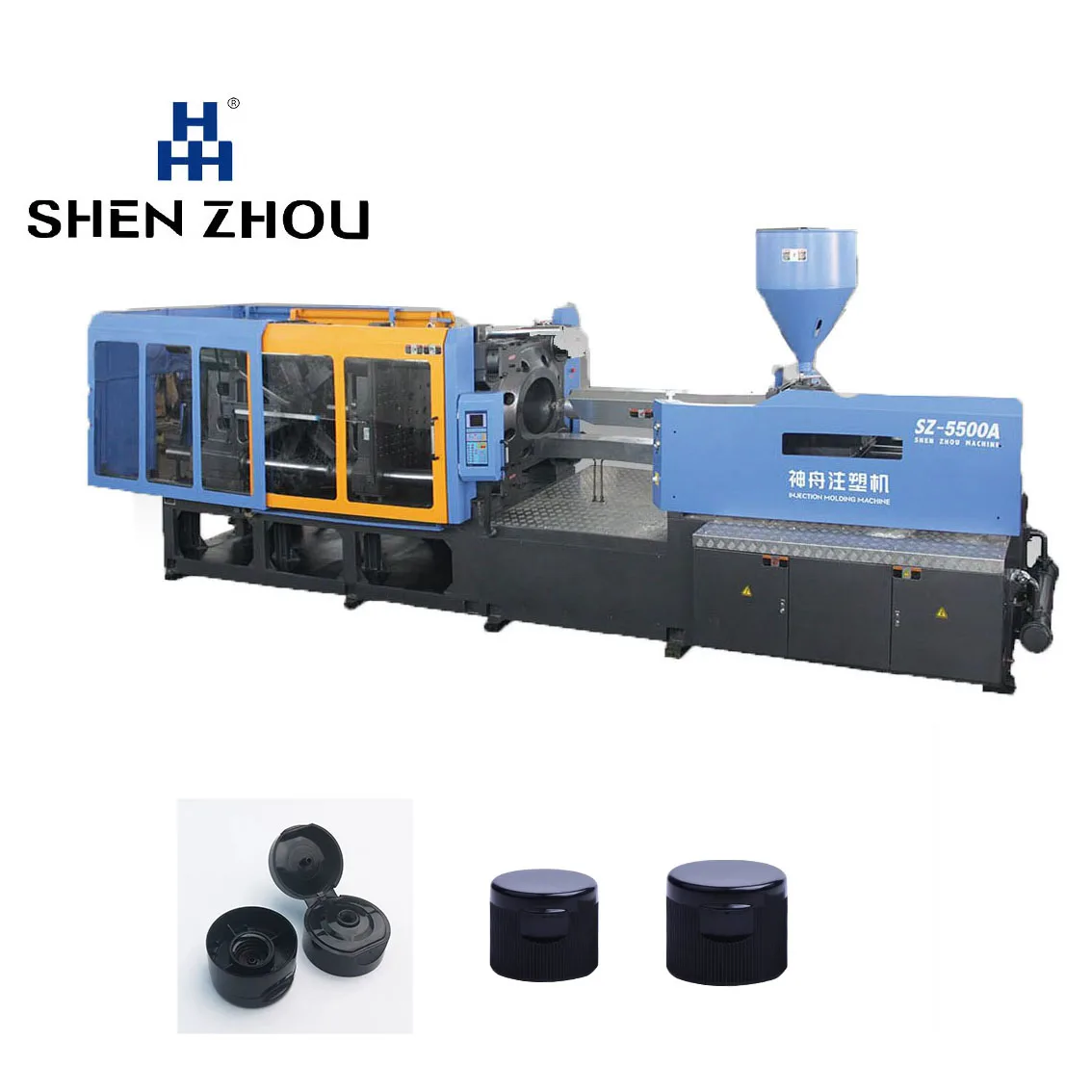

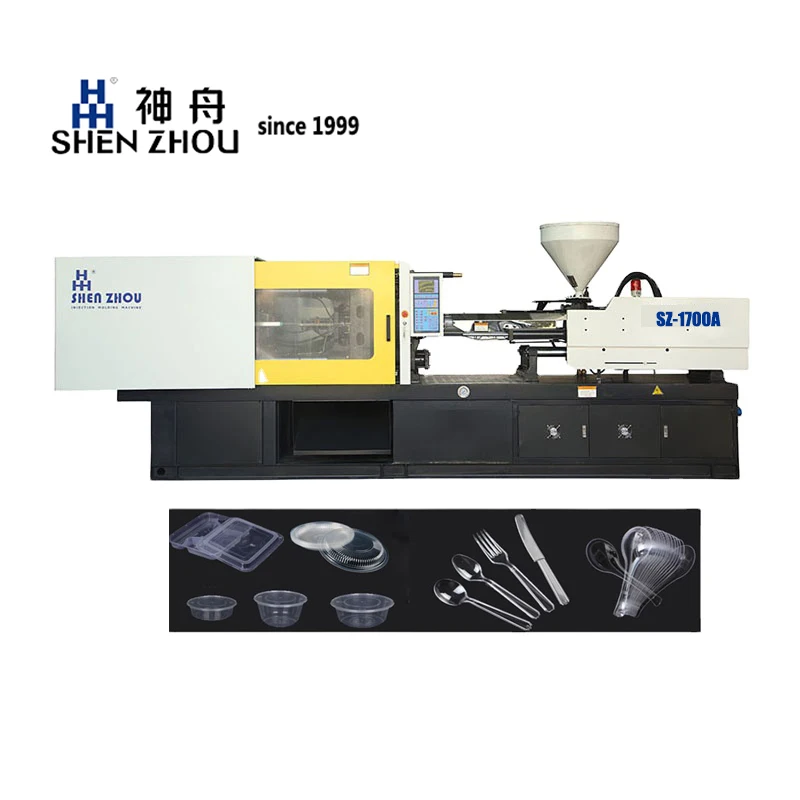

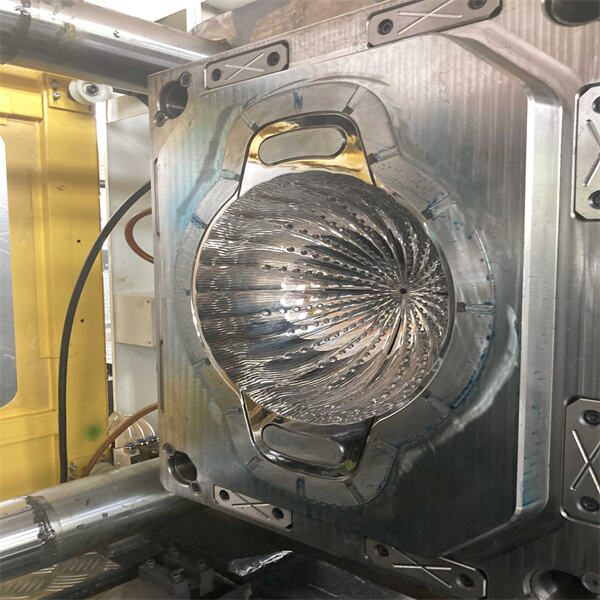

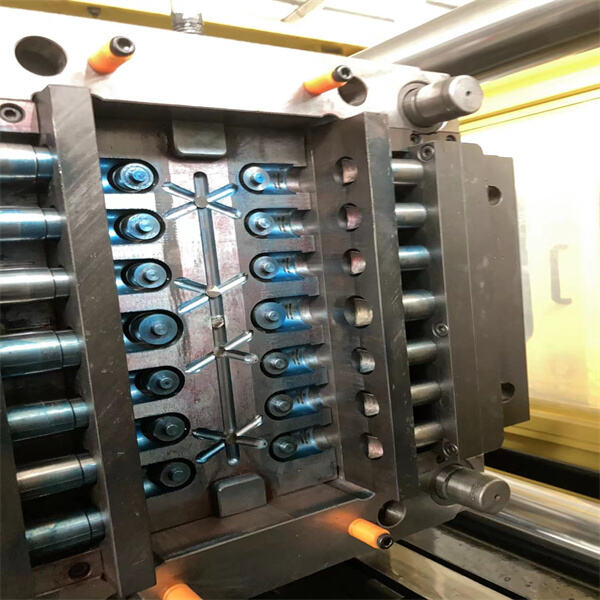

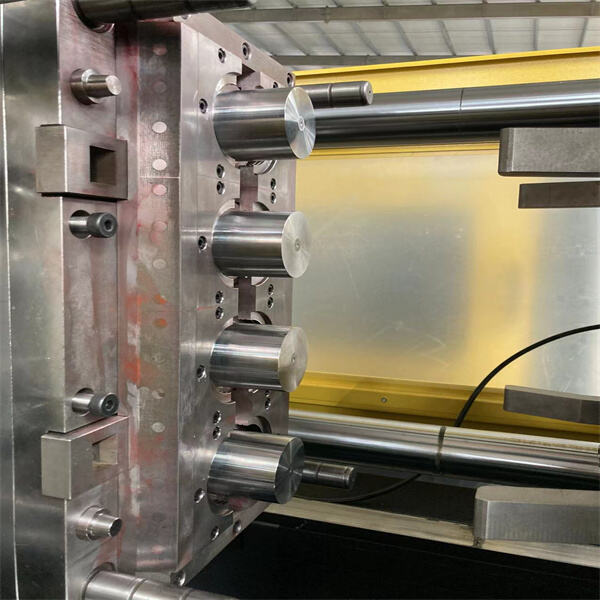

So what is custom plastic injection molding? For one, there's a specific machine that melts plastic pellets down to a warm, liquid substance. Then, the melted plastic is forced into a mold, which is basically a special container that shapes the plastic. Once the mold is full, it cools off, and the plastic takes the shape of the mold. Finally, the mold opens, and the new plastic part can be removed.