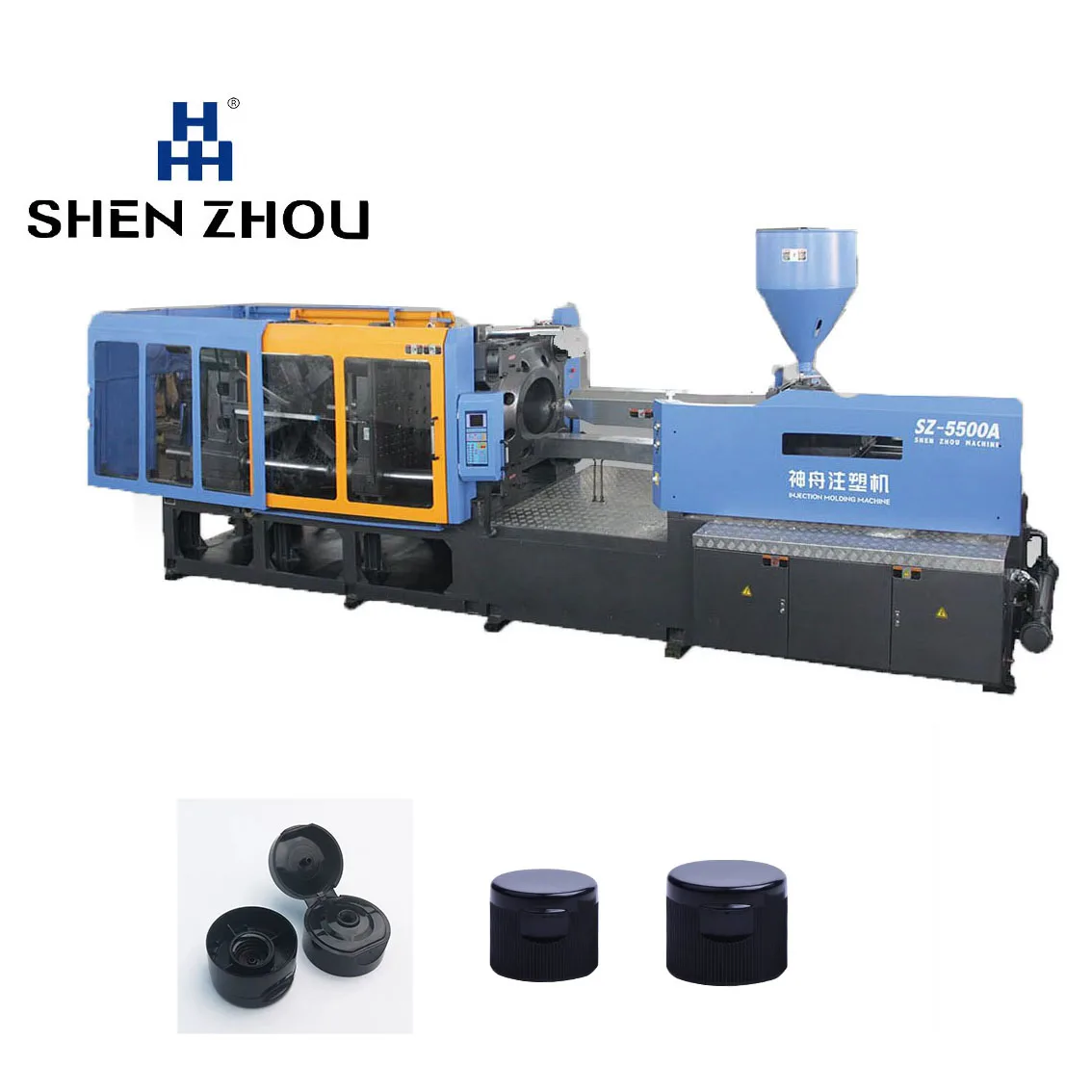

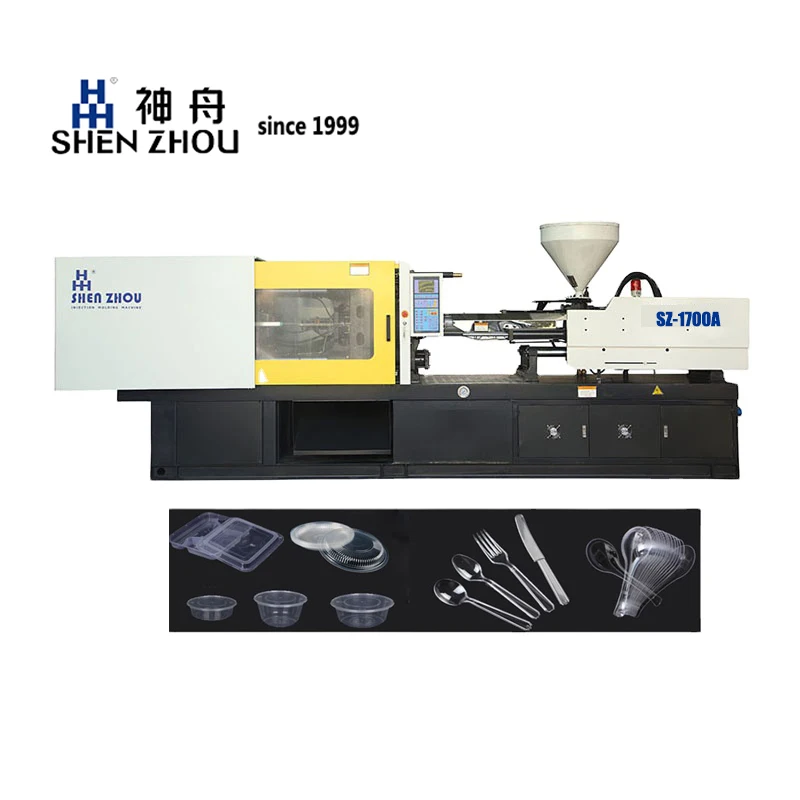

Making all sorts of things from plastic is great – SHENZHOU plastic injection moulding is a way to make a range of different types of custom plastics. That is, taking melted plastic and putting it into a shape, called a mould. This is then used to produce a wide range of items, such as toys, containers, and machine parts. Let’s learn more about what’s so cool about this process as we figure out how it works and its benefits, how it’s a time and money saver, its versatility, and how to decide which material you’ll use.

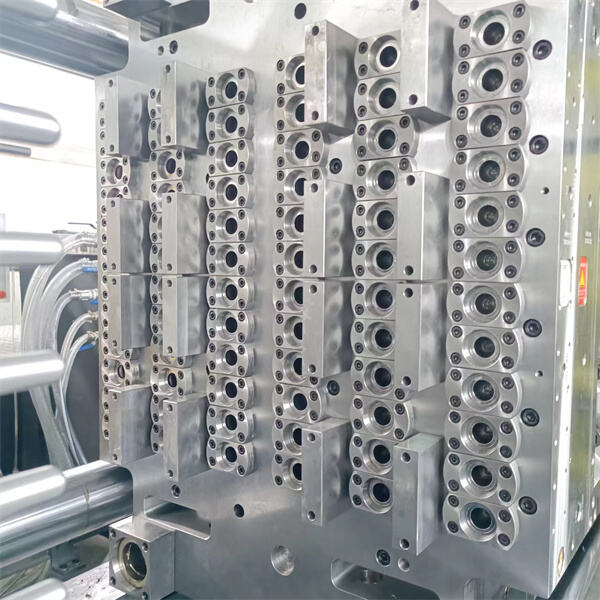

This custom plastic injection moulding process is fascinating. That begins with choosing the right kind of plastic. Once selected, the plastic is melted and made into a liquid. Then, this molten plastic is injected into a mould designed like the product we want to manufacture. Then the plastic is cooled in the mould and hardens. The mould then opens, and we pull out the new plastic item. You can do this in many campaigns to get a lot of one thing.