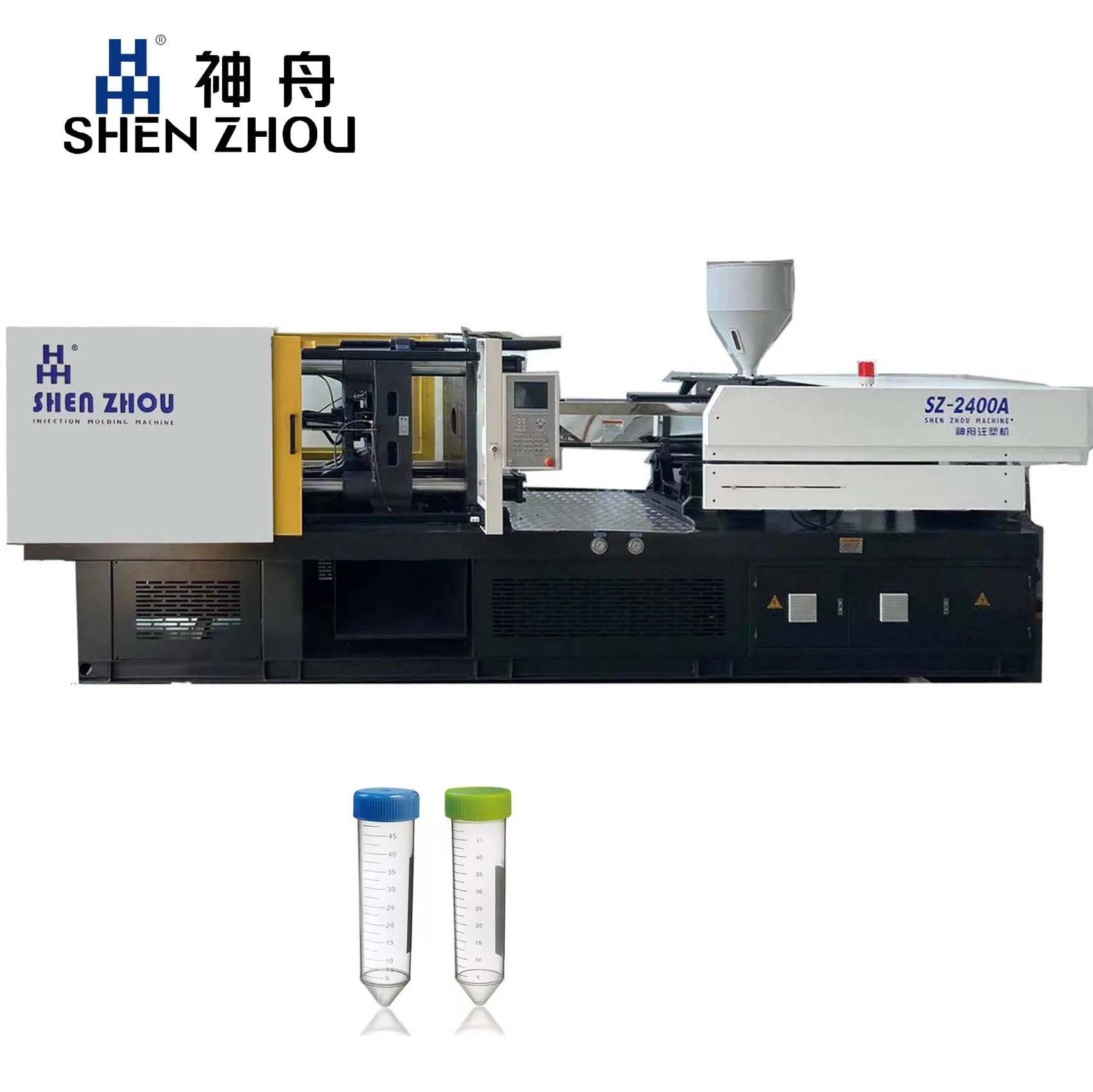

The benefits of using PP in injection moulding

A big reason that people enjoy using PP is that it is super flexible. PP is easier to color, shape and recycle, a boon for countless projects. It is as well, very sturdy and stays intact for quite a long time. And PP is also light, which is useful if you want to create things that — like cups and containers — need to be easy to carry.

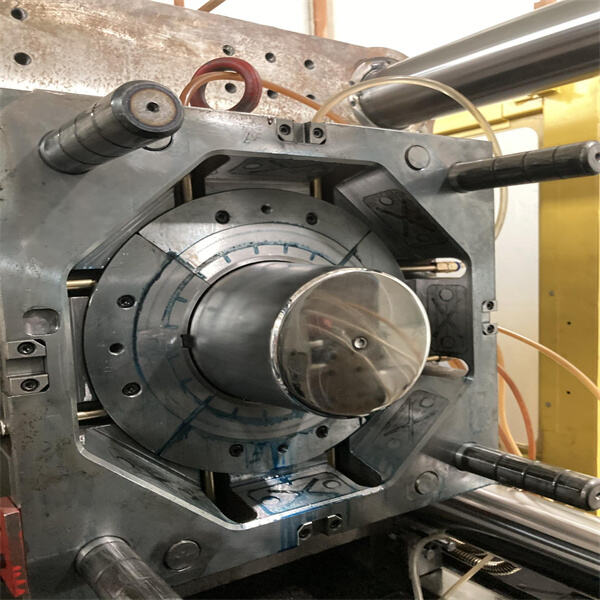

PP injection moulding is employed to manufacture a wide range of products we use every day. Pour vous, des PP objets sont disponible dans la maison, à l'école… mais aussi dans le parc! Common items produced with PP injection molding are plastic knives, storage containers, bottle caps, and parts of toys. PP is so adaptable that it can be applied to nearly anything!