The size of the injection molding machine you choose affects the efficacy of production, the quality of your parts and the longevity of the machine. This basic relationship is understood at Shenzhou Machinery. Here’s an explanation of our many injection molding machines to explain how you should select the best one:

Determine Required Clamping Force:

This is the most important point of all. The mold will only remain closed properly if the machine applies enough force against the pressure from the injection of molten plastic.

Shenzhou Machinery Solution: Review the design of your mold and the materials being considered for the parts. Using machines with a rated tonnage close to what you require helps the machine work well.

Calculate Injection Volume:

There should be enough plasticizing power so that the machine can fill every part of the mold which commonly calls for 20-30% extra capacity beyond the shot weight of the molding.

With Shenzhou Machinery Solution: Determine the overall shot weight, see if it’s within the range specified by the Theoretical Injection Volume of our machines. Pick a shot size that is no more than 70-90% of the machine’s maximum so you get even and abundant cushion every time.

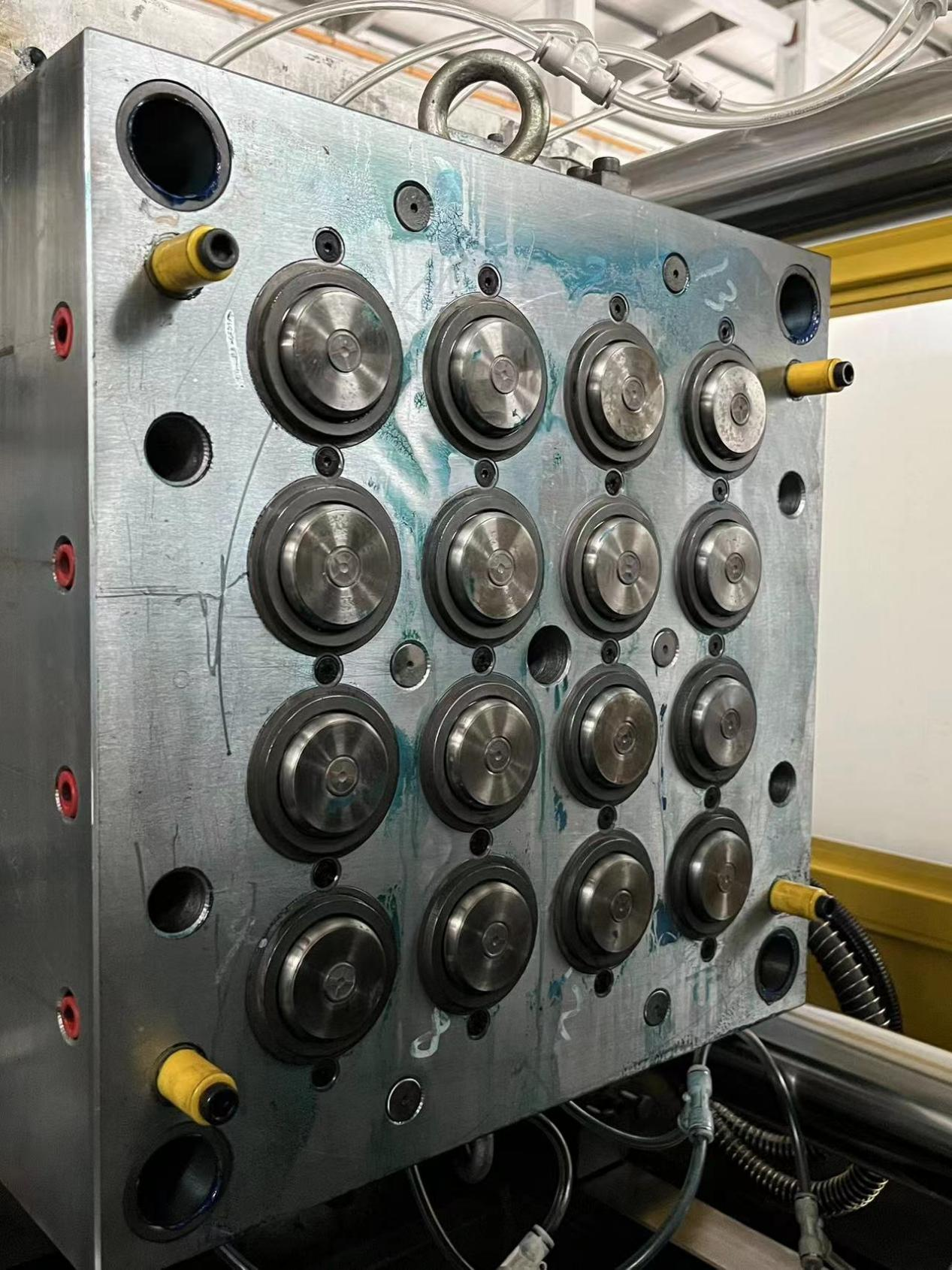

Check Mold Dimensions and Machine Specifications:

The mold must have a thickness within the machine’s Min. and Max range. Mold Height.

Mold Width and Length: Check that Mold Width and Length are comfortable within the machine’s Tie-Bar Spacing.

Ejection Stroke: Max it up with the ejection drink following the instructions. Using an Ejection Stroke will be enough to provide part ejection.

Shenzhou Machinery Solution: Our detailed machine specifications on the website provide exact dimensions like Tie-Bar Spacing, Mold Height Range, and Ejection Stroke for each model. Measure your mold carefully and compare.

Why Partner with Shenzhou Machinery?

A match that is perfectly exact in specs is only as good as the precision and reliable function it provides. Shenzhou Machinery machines are designed to be tough and supply steady results. Styles and sizes in our line allow us to respond to any mold need. If the selection isn’t clear to you, please get in touch with our technical team and explain your mold situation and they will recommend the best machine for you.