Understanding plastic cap injection machines will improve our factory to be better and faster.

Making plastic caps is all about using good methods to make things quickly.

Facilitating our production and shortening waiting times allow us to produce more caps to continue following people's demand. That can involve speeding up the machines, changing their settings and employing automatic processes where we can.

Proper maintenance to ensure their longevity.

This will help to prevent the machines from breaking and will contribute to a longer life of the injection machine — check the machines regularly, clean them, and put oil on key components. When we look after our machines, we can save money and get more out of what we invest.

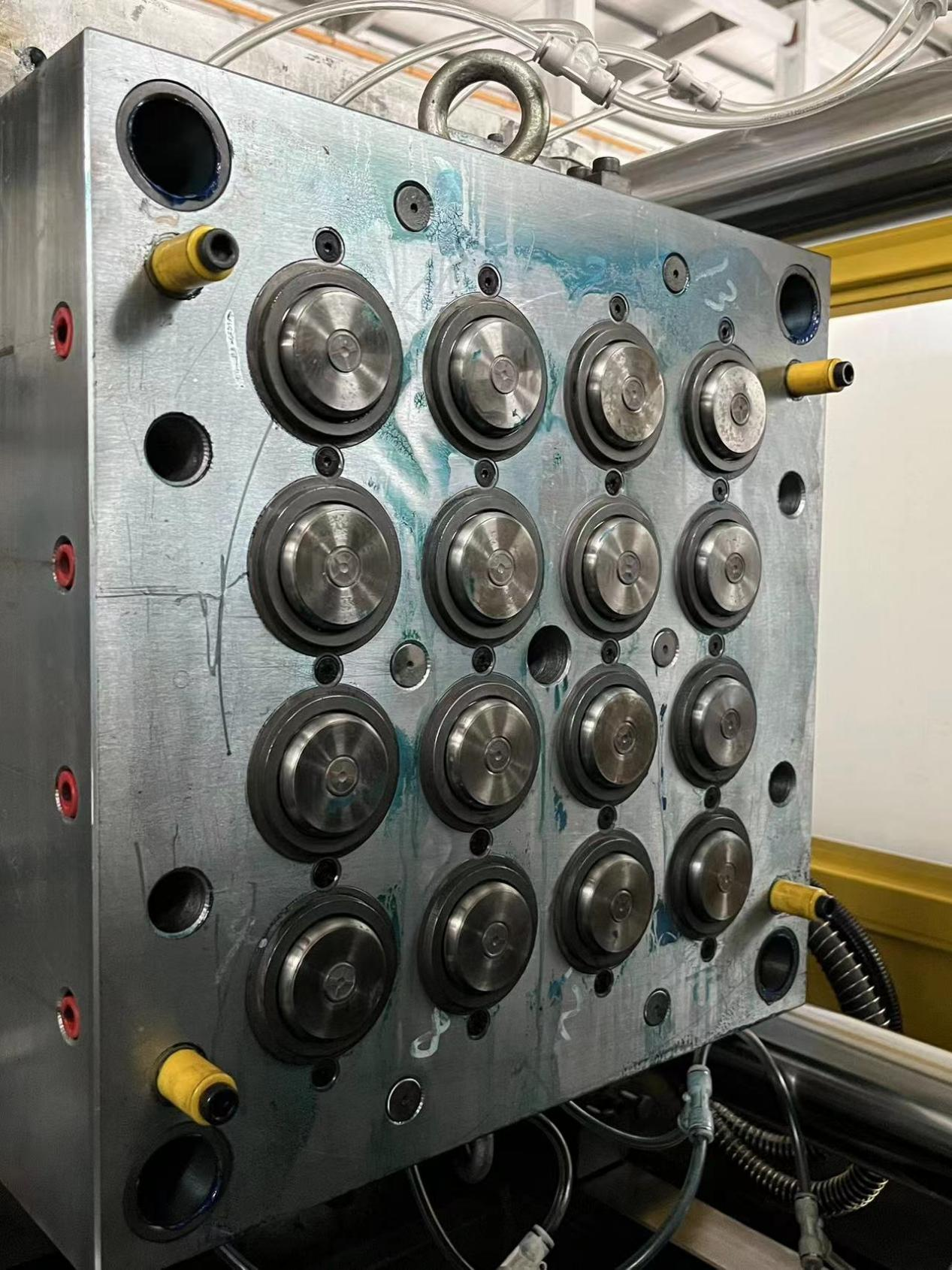

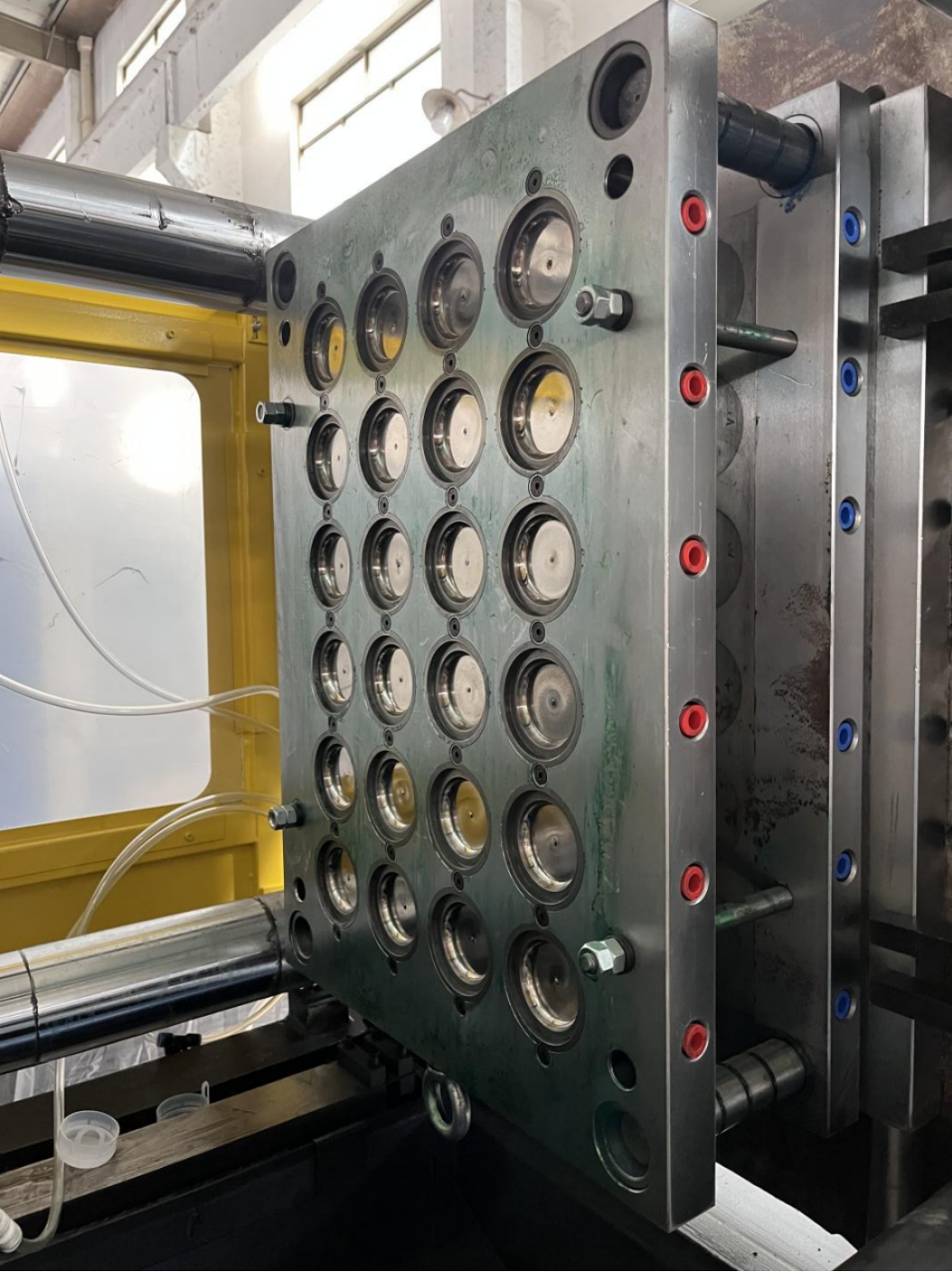

In order to produce the best caps, we must consider the mold designs and materials involved.

By designing good molds and using the right materials, we can produce caps in a high quality, fast manner. We make good choices in materials and mold designs that provide caps that our customers prefer.

Everything we do in production is a part of the factory itself

And we must continually consider how to improve that work to improve the factory's performance, profit, and cash flow. This includes better functioning by the machines, good practice, machine maintenance, appropriate materials and mold designs, etc. We could win in the market developing by improving constantly and by

innovating injection machines.