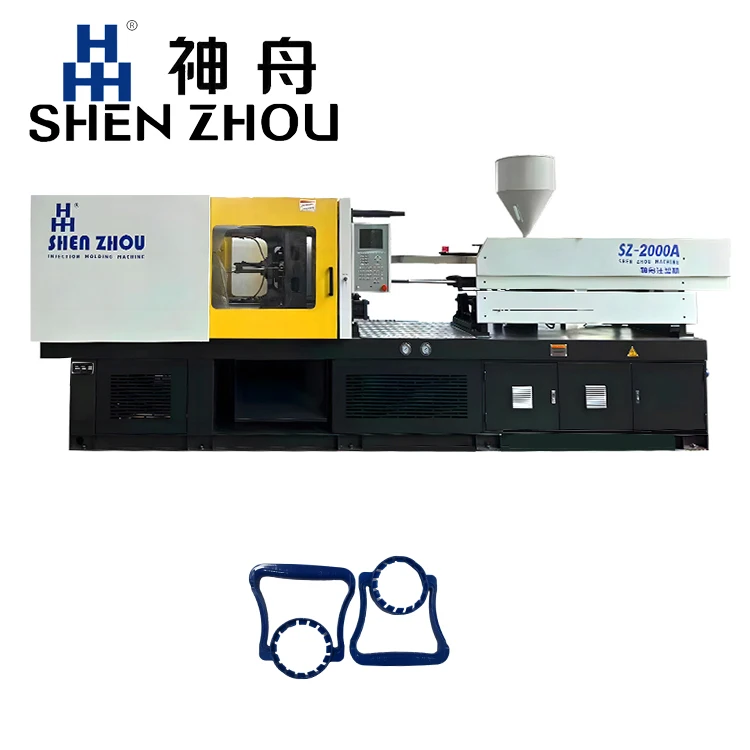

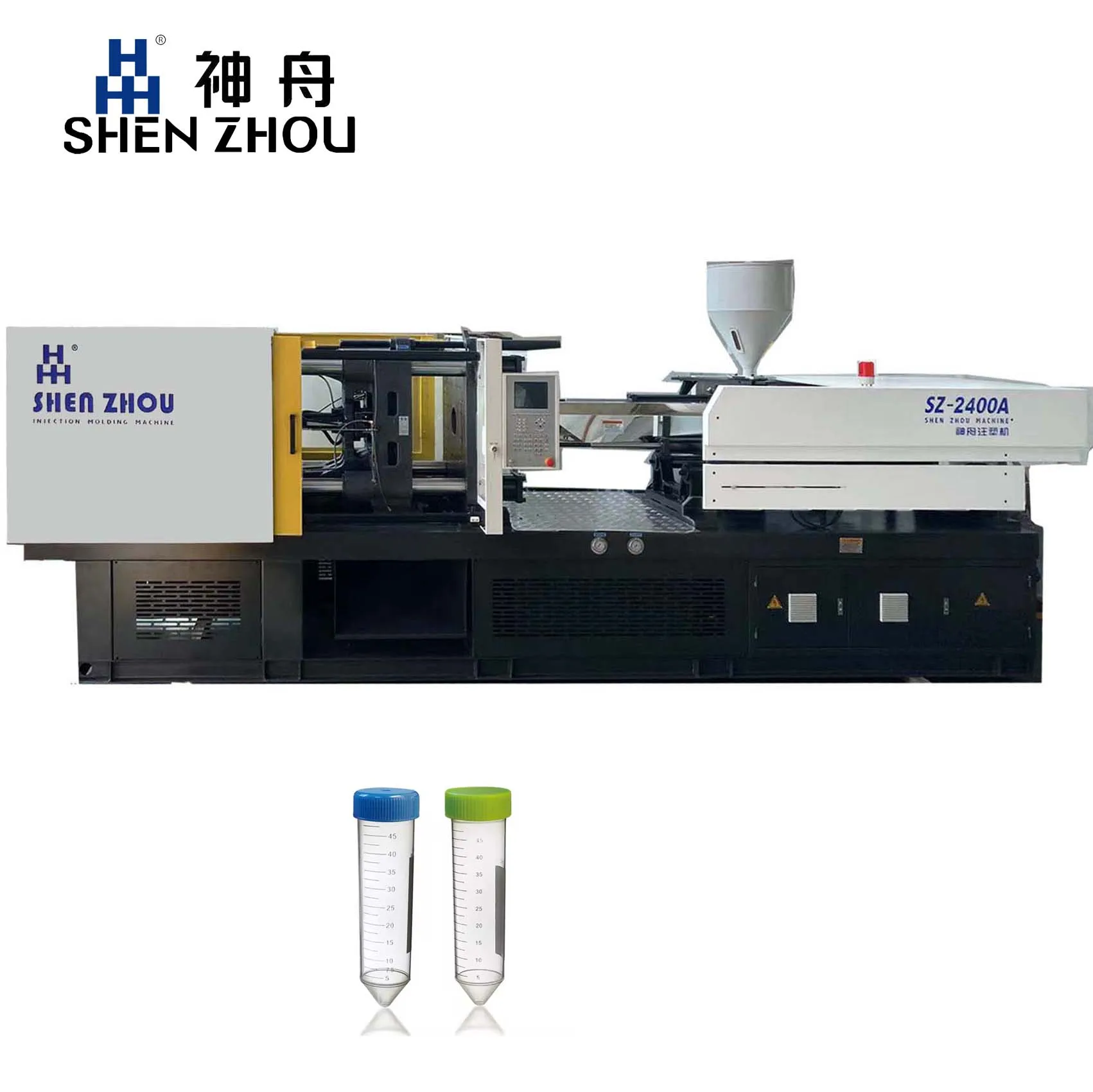

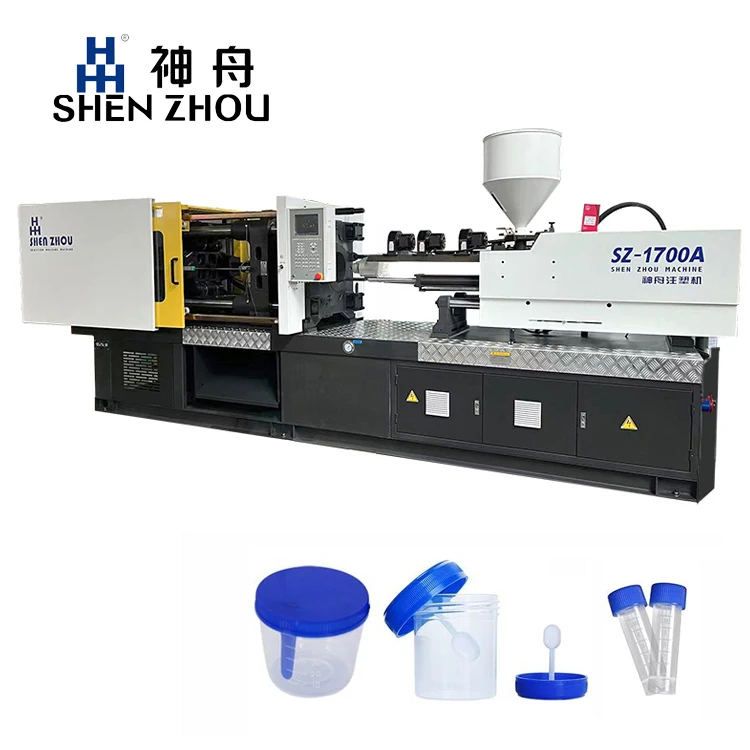

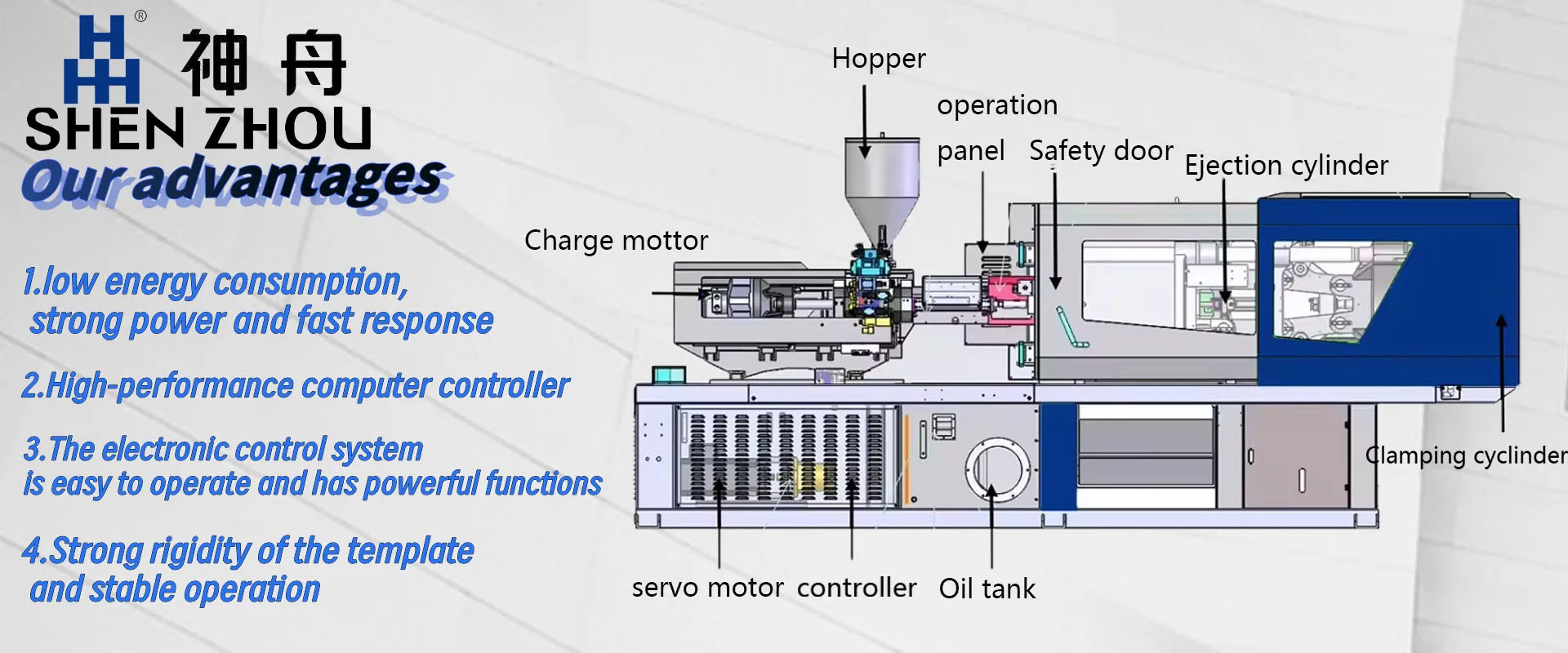

Plastic 5L 10L ASA Carrying Bottle Handle Injection Molding Machine

The core features of ASA handles

ASA (acrylonitrile-styrene-acrylate copolymer) is an outdoor weather-resistant engineering plastic. The oil drums, mineral water bottles, chemical drums and outdoor bucket handles made from it have comprehensive performance that far exceeds that of conventional PP/HDPE materials, and it is also the preferred raw material for high-end handles

Description

The core features of ASA handles

This is the most core advantage of ASA, which has an excellent UV resistance. Even when exposed to sunlight, rain, high temperatures and severe cold for a long time, it does not fade, powderize, crack or become brittle, and its weather resistance life can reach 5 to 8 years. In contrast, PP/HDPE handles tend to become brittle, break and turn yellow after 1-2 years of outdoor use. ASA handles completely solve this problem and are particularly suitable for handling oil drums and chemical drums that are stored and transported outdoors.It has excellent high and low temperature toughness and extremely strong load-bearing and impact resistance

Its toughness far exceeds that of PP/HDPE. It is not prone to deformation when bent or pulled at room temperature. It has outstanding low-temperature cold resistance (in an ultra-low temperature environment of -30℃) and can still maintain high toughness without cracking. The impact resistance is over 30% higher than that of ordinary PP. When used as an oil drum handle, it has stronger load-bearing stability. It is not easy to break even when fully loaded with heavy objects and lifted or dropped. The safety is at its peak and it is suitable for use in various heavy-duty oil drums and chemical drums.

The surface texture is excellent, and it is easy to maintain without spraying.

ASA raw material naturally has a uniform high gloss/matte finish. After molding, the surface of the handle is smooth and fine without pockmarks. There is no need for secondary painting or grinding treatment. It can be directly formed to achieve a high appearance level. At the same time, it has a high surface hardness, is wear-resistant and scratch-resistant. It will not leave scratches due to friction or impact during daily use, and its appearance remains as good as new for a long time. It is suitable for the handle requirements of high-end mineral water bottles, beverage gift boxes, and branded packaging buckets.

It has good chemical stability, is resistant to corrosion, dirt and easy to clean.

It has excellent chemical resistance and can withstand the erosion of common media such as edible oil, daily chemical solvents, weak acids and alkalis, without swelling, deformation or cracking. The surface is hydrophobic and oleophobic, and stains and oil stains can be wiped off easily. It is not easy to accumulate dust and is suitable for the handles of edible oil drums and food-grade packaging drums. It can also meet the corrosion resistance requirements of chemical drums and industrial packaging drums.

Its toughness far exceeds that of PP/HDPE. It is not prone to deformation when bent or pulled at room temperature. It has outstanding low-temperature cold resistance (in an ultra-low temperature environment of -30℃) and can still maintain high toughness without cracking. The impact resistance is over 30% higher than that of ordinary PP. When used as an oil drum handle, it has stronger load-bearing stability. It is not easy to break even when fully loaded with heavy objects and lifted or dropped. The safety is at its peak and it is suitable for use in various heavy-duty oil drums and chemical drums.

The surface texture is excellent, and it is easy to maintain without spraying.

ASA raw material naturally has a uniform high gloss/matte finish. After molding, the surface of the handle is smooth and fine without pockmarks. There is no need for secondary painting or grinding treatment. It can be directly formed to achieve a high appearance level. At the same time, it has a high surface hardness, is wear-resistant and scratch-resistant. It will not leave scratches due to friction or impact during daily use, and its appearance remains as good as new for a long time. It is suitable for the handle requirements of high-end mineral water bottles, beverage gift boxes, and branded packaging buckets.

It has good chemical stability, is resistant to corrosion, dirt and easy to clean.

It has excellent chemical resistance and can withstand the erosion of common media such as edible oil, daily chemical solvents, weak acids and alkalis, without swelling, deformation or cracking. The surface is hydrophobic and oleophobic, and stains and oil stains can be wiped off easily. It is not easy to accumulate dust and is suitable for the handles of edible oil drums and food-grade packaging drums. It can also meet the corrosion resistance requirements of chemical drums and industrial packaging drums.

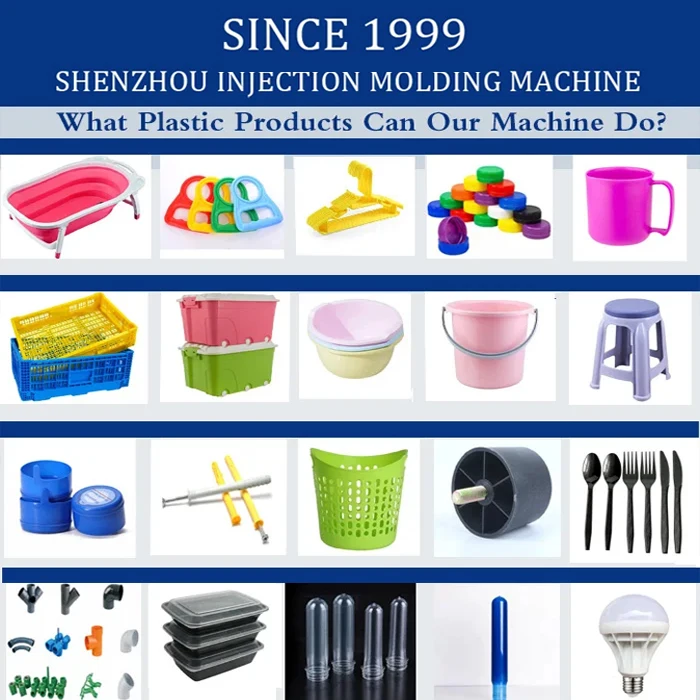

Products Description

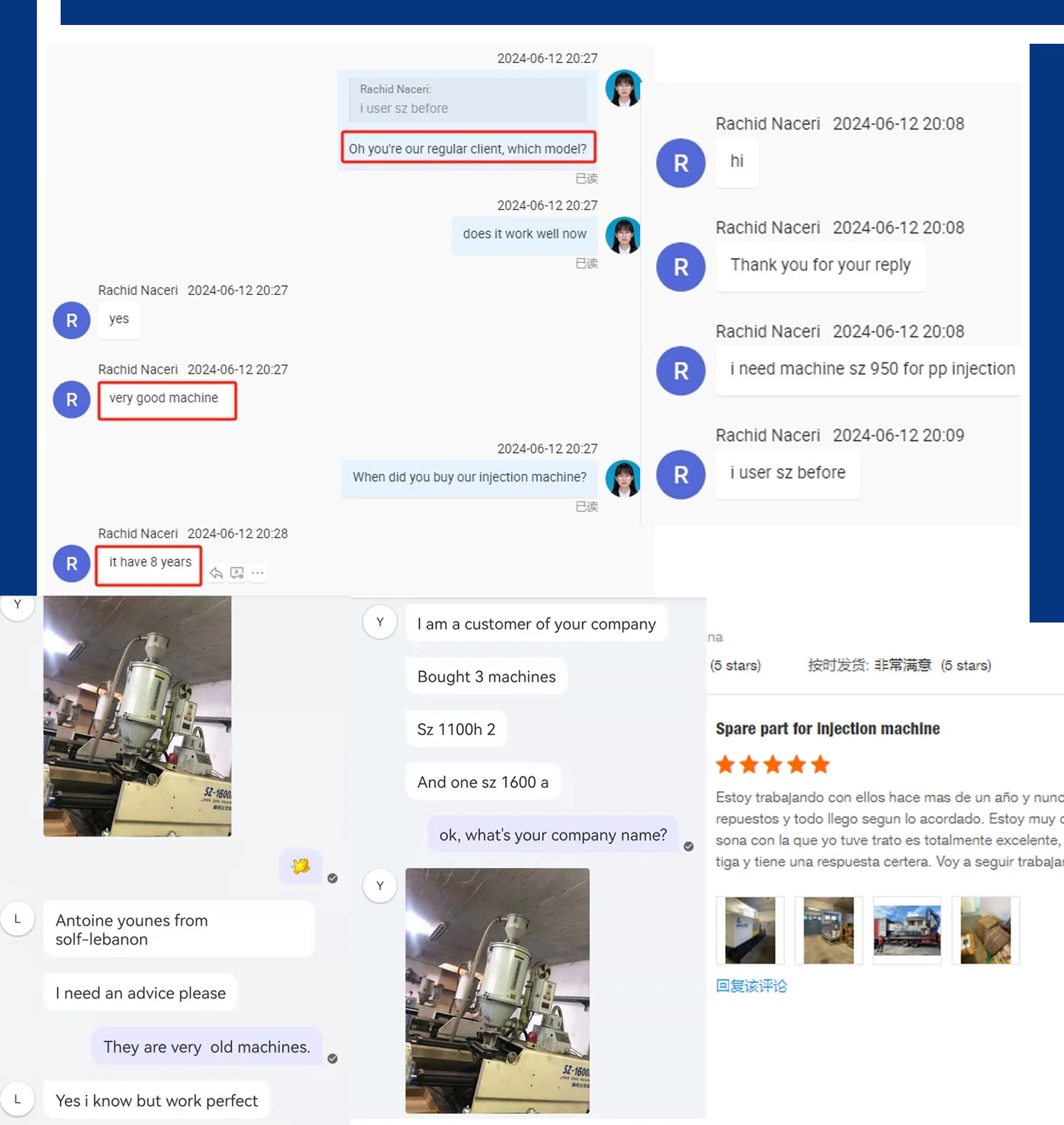

reviews

Certifications

Company Information

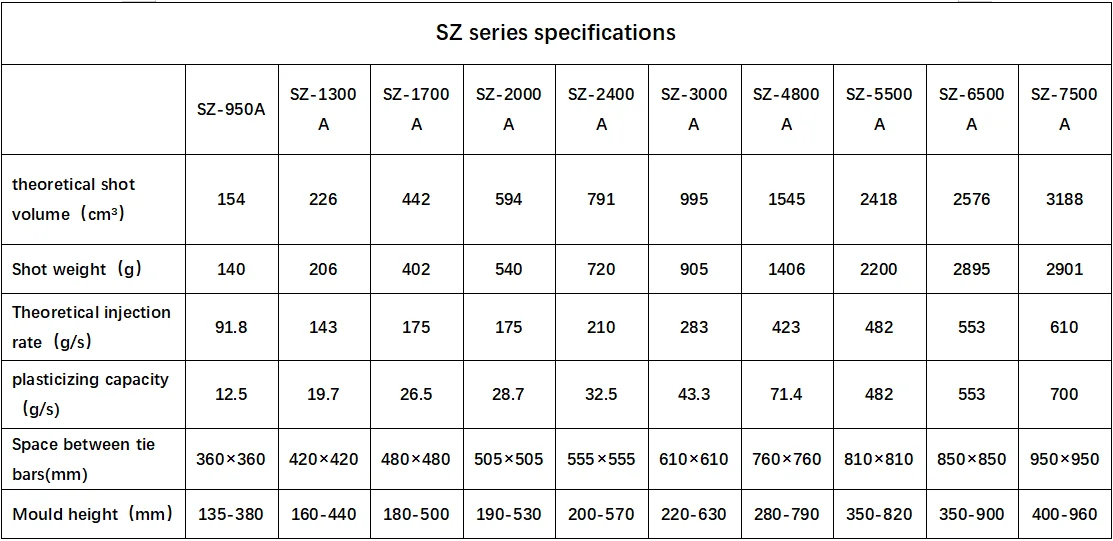

Technical Parameter

项目 ITEM |

单位UNIT |

SZ—2400A |

|||||||

注射装置 INJECTION UNIT |

|||||||||

螺杆直径 |

SCREW DIAMETER |

mm |

55 |

60 |

65 |

||||

螺杆长径比 |

SCREW LID RATIO |

L/D |

22.9 |

21 |

19.4 |

||||

理论注射容积 |

THEORETICAL SHOT VOLUME |

CM3 |

665 |

791 |

929 |

||||

注射质量(PS料) |

SHOT WEIGHT(PS) |

g |

605 |

720 |

845 |

||||

注射压力 |

INJECTION PRESSURE |

Mpa |

210 |

176 |

150 |

||||

理论注射速率(PS料) |

THEORETICAL INJECTION RATE(PS) |

g/s |

176.5 |

210 |

245 |

||||

塑化能力(PS料) |

PLASTICISING CAPACITY |

g/s |

26.4 |

32.5 |

40 |

||||

螺杆驱动扭矩 |

SCREW TORQUE |

N.m |

2000 |

||||||

螺杆最高转速 |

MAX.SCREW ROTATE SPEED |

r/min |

150 |

||||||

洼射行程 |

INJECTION STROKE |

mm |

280 |

||||||

合模装置 CLAMPING UNIT |

|||||||||

合模力 |

MAX.CLAMPING FORCE K |

KN |

2400 |

||||||

移模行程 |

MAX.OPENING STROKE |

mm |

530 |

||||||

拉杆有效间距(VxH) |

SPACE BETWEEN TIE BARS |

mm |

555×555 |

||||||

允许模厚(MIN-MAX) |

MOULD HEIGHT |

mm |

200-570 |

||||||

模板最大开距 |

MAX.DAYLIGHT |

mm |

1100 |

||||||

液压顶出力 |

EJECTOR FORCE |

KN |

61.5 |

||||||

液压顶出行程 |

EJECTOR STROKE |

mm |

135 |

||||||

液压顶出杆总数 |

EJECTOR QUANTITY |

9 |

|||||||

其它 OTHER |

|||||||||

油泵电动机功率 |

PUMP MOTOR POWER |

KW |

22 |

||||||

油泵最高压力 |

PUMP PRESSURE |

Mpa |

16 |

||||||

料简加热功率 |

HEATING POWER |

KW |

18.5 |

||||||

加热区段 |

HEATING ZONE |

5 |

|||||||

机器外形(LxWxH) |

SIZE |

m |

6.2×1.6×2.1 |

||||||

机器净重 |

NET WEIGHT |

t |

8.0 |

||||||

油箱容积 |

OIL TANK CAPACITY |

L |

440 |

||||||

国际公认型号 |

INTERNATIONAL DESIGNATION |

2400—1390 |

|||||||

Exhibition

FAQ

1.Q:Are you a factory or trading company? A: Industry and Trade Integration, we supply the factory price with good quality, welcome to visit ! 2.Q:How does your factory do regarding quality control? A:"Quality is priority. we always attach great importance to quality controlling from the very beginning to the very end and we have a dedicated quality control department. 3.Q:What are your normal lead times? A:Our company typical lead times range from 25-35days after receipt of order.We also have independent venues and engineers to deal with more urgent orders, which can be shipped within 2 weeks. 4.Q:About the price? A:We will estimate the cost and provide you with the best price. We can guarantee you the best product quality and after-sales service at the same price. Old customers will enjoy more price concessions. 5.Q:How is your machine different from other businesses? A:We have optimized the overall layout of each part of the machine to make the machine run smoothly and have a longer service life. The fine parts have exclusive marks, which makes it more convenient for customers to replace parts and use. 6.Q:Where is your factory located? How can I visit there? A: Our factory is located in Shenzhou Machinery, No. 22 Zhenbei Road, Fenghuang Town, Zhangjiagang City China. All our clients,from home or abroad, are warmly welcome to visit us!

You are welcome to send us samples, we will customize high-quality machines for you! Best wishes for you!