Description

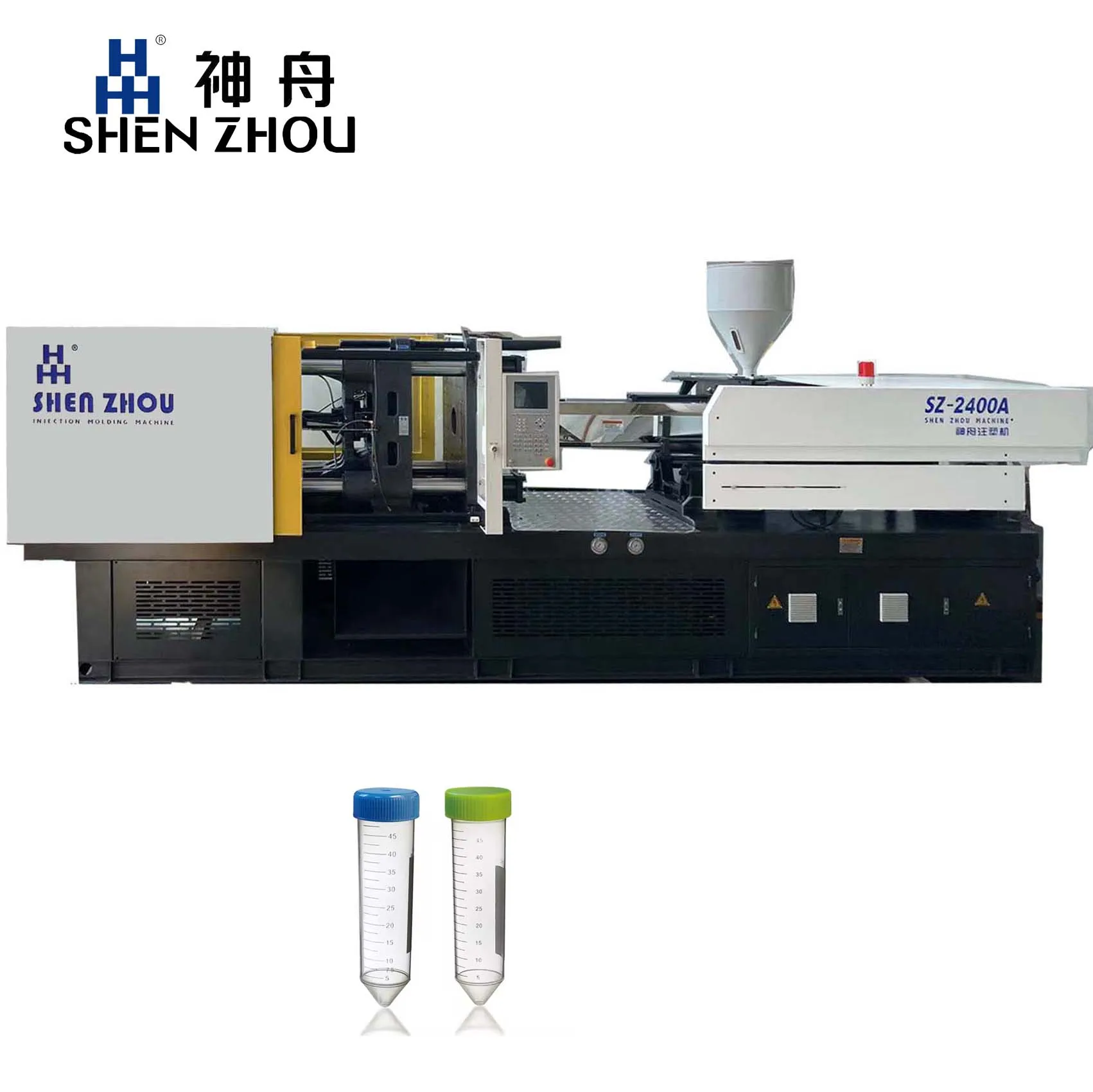

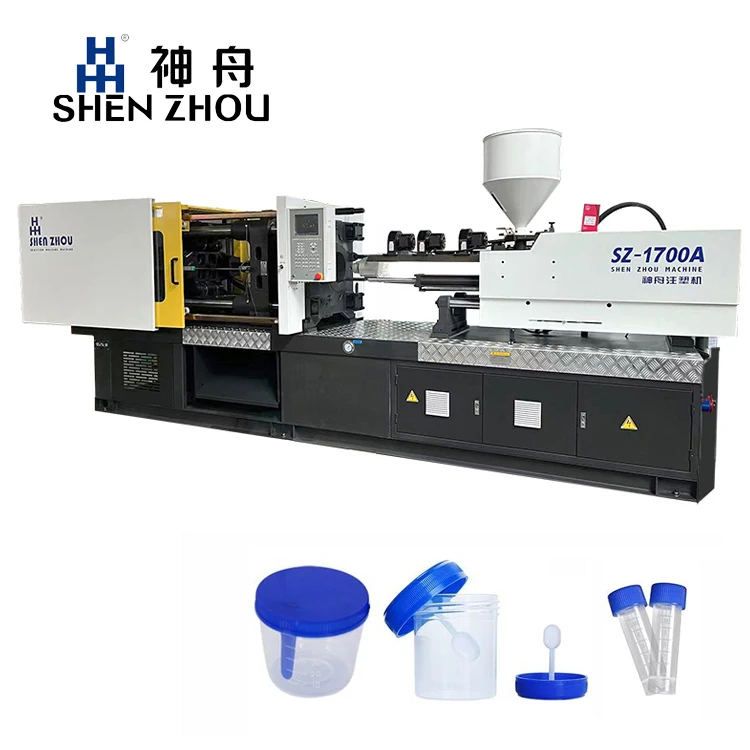

Introducing, the SHENZHOU’s Custom Clear Plastic PVC Cups with Lids Making Injection Molding Machine, the ultimate solution for creating high-quality, customizable plastic cups with ease. This state-of-the-art machine is designed to streamline the production process, making it perfect for businesses looking to meet the demand for custom-branded cups.

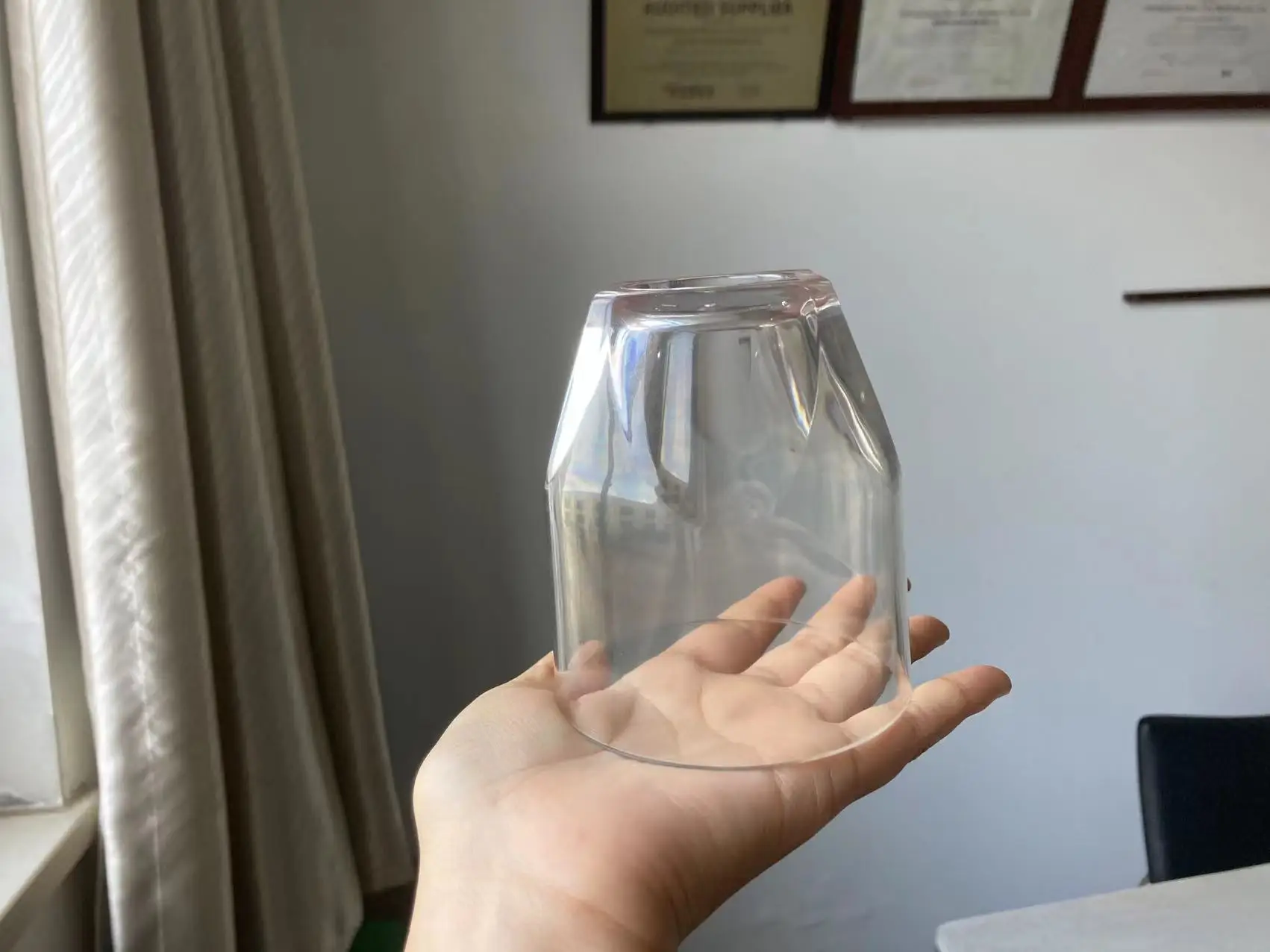

With this machine, you can easily create clear plastic cups with secure lids in a variety of shapes and sizes. Whether you need to produce simple, no-frills cups or want to create eye-catching designs with intricate details, this machine can handle it all. The precision injection molding technology ensures that each cup is consistently shaped and finished to perfection, giving your products a professional look that will impress even the most discerning customers.

One of the key features of the SHENZHOU’s Custom Clear Plastic PVC Cups with Lids Making Injection Molding Machine is its versatility. This machine is compatible with a wide range of materials, allowing you to experiment with different types of plastic to achieve the exact look and feel you desire. From lightweight, flexible cups to more durable, rigid options, the possibilities are endless with this machine.

Another standout feature of this machine is its user-friendly design. The intuitive controls make it easy to operate, even for beginners, while the automated functions help to minimize human error and increase efficiency. With the ability to produce up to hundreds of cups per hour, this machine is ideal for businesses of all sizes, from small start-ups to large-scale manufacturers.

In addition to its impressive productivity, the SHENZHOU’s Custom Clear Plastic PVC Cups with Lids Making Injection Molding Machine is also designed with durability in mind. Constructed from high-quality materials, this machine is built to last, ensuring that you can rely on it for years to come. Plus, with its compact size and efficient energy consumption, this machine is also eco-friendly, making it a smart choice for environmentally conscious businesses.

The SHENZHOU’s Custom Clear Plastic PVC Cups with Lids Making Injection Molding Machine is a must-have for any business looking to elevate their cup production process. With its precision technology, versatility, user-friendly design, and durability, this machine is sure to take your business to the next level. Upgrade your production line today with this top-of-the-line machine and start creating custom plastic cups that will set your brand apart from the competition

项目 ITEM |

单位UNIT |

SZ—4000A |

|||||||

注射装置 INJECTION UNIT |

|||||||||

螺杆直径 |

SCREW DIAMETER |

mm |

70 |

75 |

80 |

||||

螺杆长径比 |

SCREW LID RATIO |

L/D |

21.4 |

20 |

18.8 |

||||

理论注射容积 |

THEORETICAL SHOT VOLUME |

CM3 |

1293 |

1485 |

1689 |

||||

注射质量 - PS料 |

SHOT WEIGHT - PS |

g |

1176 |

1351 |

1537 |

||||

注射压力 |

INJECTION PRESSURE |

Mpa |

199 |

173 |

152 |

||||

理论注射速率 - PS料 |

THEORETICAL INJECTION RATE - PS |

g/s |

366 |

395 |

446 |

||||

塑化能力 - PS料 |

PLASTICISING CAPACITY |

g/s |

60 |

65 |

70 |

||||

螺杆驱动扭矩 |

SCREW TORQUE |

N/m |

4200 |

||||||

螺杆最高转速 |

MAX. SCREW ROTATE SPEED |

r/min |

165 |

||||||

洼射行程 |

INJECTION STROKE |

mm |

335 |

||||||

合模装置 CLAMPING UNIT |

|||||||||

合模力 |

MAX. CLAMPING FORCE K |

KN |

4000 |

||||||

移模行程 |

MAX. OPENING STROKE |

mm |

700 |

||||||

拉杆有效间距 - VxH |

SPACE BETWEEN TIE BARS |

mm |

720×720 |

||||||

允许模厚 - MIN-MAX |

MOULD HEIGHT |

mm |

280-800 |

||||||

模板最大开距 |

MAX. DAYLIGHT |

mm |

1500 |

||||||

液压顶出力 |

EJECTOR FORCE |

KN |

126 |

||||||

液压顶出行程 |

EJECTOR STROKE |

mm |

180 |

||||||

液压顶出杆总数 |

EJECTOR QUANTITY |

13 |

|||||||

其它 OTHER |

|||||||||

油泵电动机功率 |

PUMP MOTOR POWER |

KW |

37 |

||||||

油泵最高压力 |

PUMP PRESSURE |

Mpa |

16 |

||||||

料简加热功率 |

HEATING POWER |

KW |

25 |

||||||

加热区段 |

HEATING ZONE |

5 |

|||||||

机器外形 - LxWxH |

SIZE |

m |

7.15×2.1×2.35 |

||||||

机器净重 |

NET WEIGHT |

t |

16.7 |

||||||

油箱容积 |

OIL TANK CAPACITY |

L |

820 |

||||||

国际公认型号 |

INTERNATIONAL DESIGNATION |

4000—2570 |

|||||||

A: Industry and Trade Integration, we supply the factory price with good quality, welcome to visit

2. Q:How does your factory do regarding quality control

A:"Quality is priority. We always attach great importance to quality controlling from the very beginning to the very end and we have a dedicated quality control department

3. Q:What are your normal lead times

A:Our company typical lead times range from 25-35days after receipt of order. We also have independent venues and engineers to deal with more urgent orders, which can be shipped within 2 weeks

4. Q:About the price

A:We will estimate the cost and provide you with the best price. We can guarantee you the best product quality and after-sales service at the same price. Old customers will enjoy more price concessions

5. Q:How is your machine different from other businesses

A:We have optimized the overall layout of each part of the machine to make the machine run smoothly and have a longer service life. The fine parts have exclusive marks, which makes it more convenient for customers to replace parts and use

6. Q:Where is your factory located? How can I visit there

A: Our factory is located in Shenzhou Machinery, No. 22 Zhenbei Road, Fenghuang Town, Zhangjiagang City China. All our clients, from home or abroad, are warmly welcome to visit us