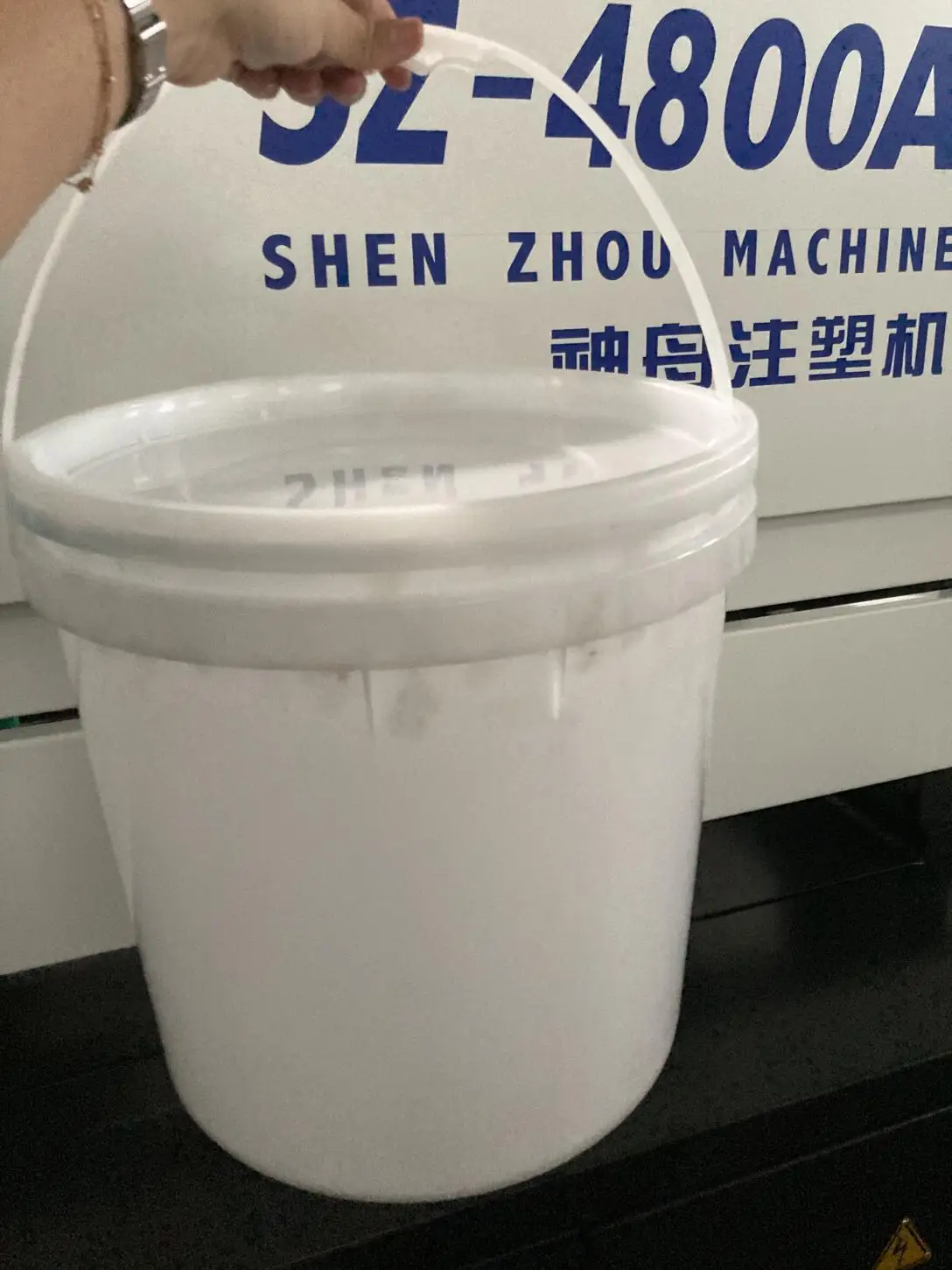

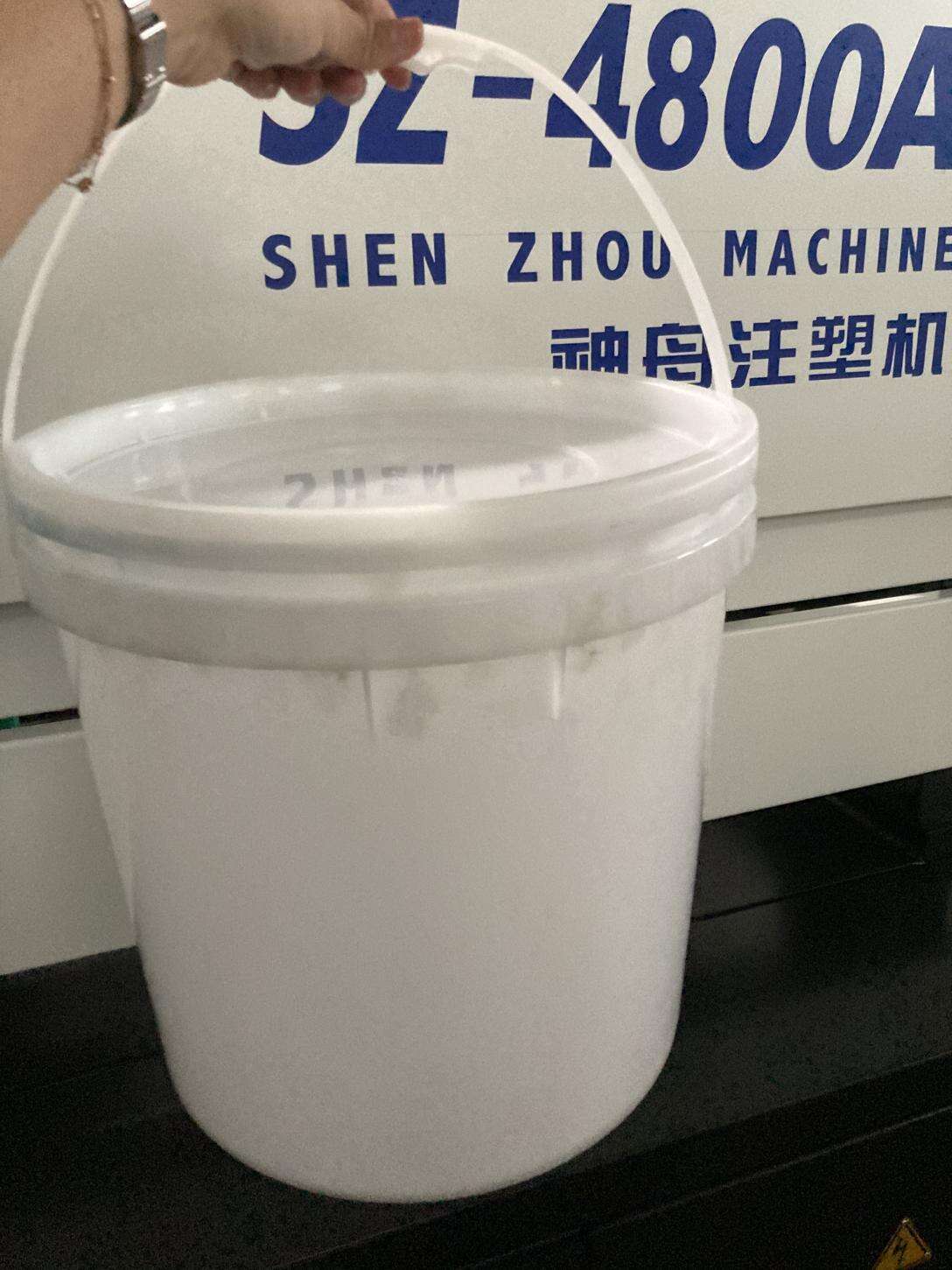

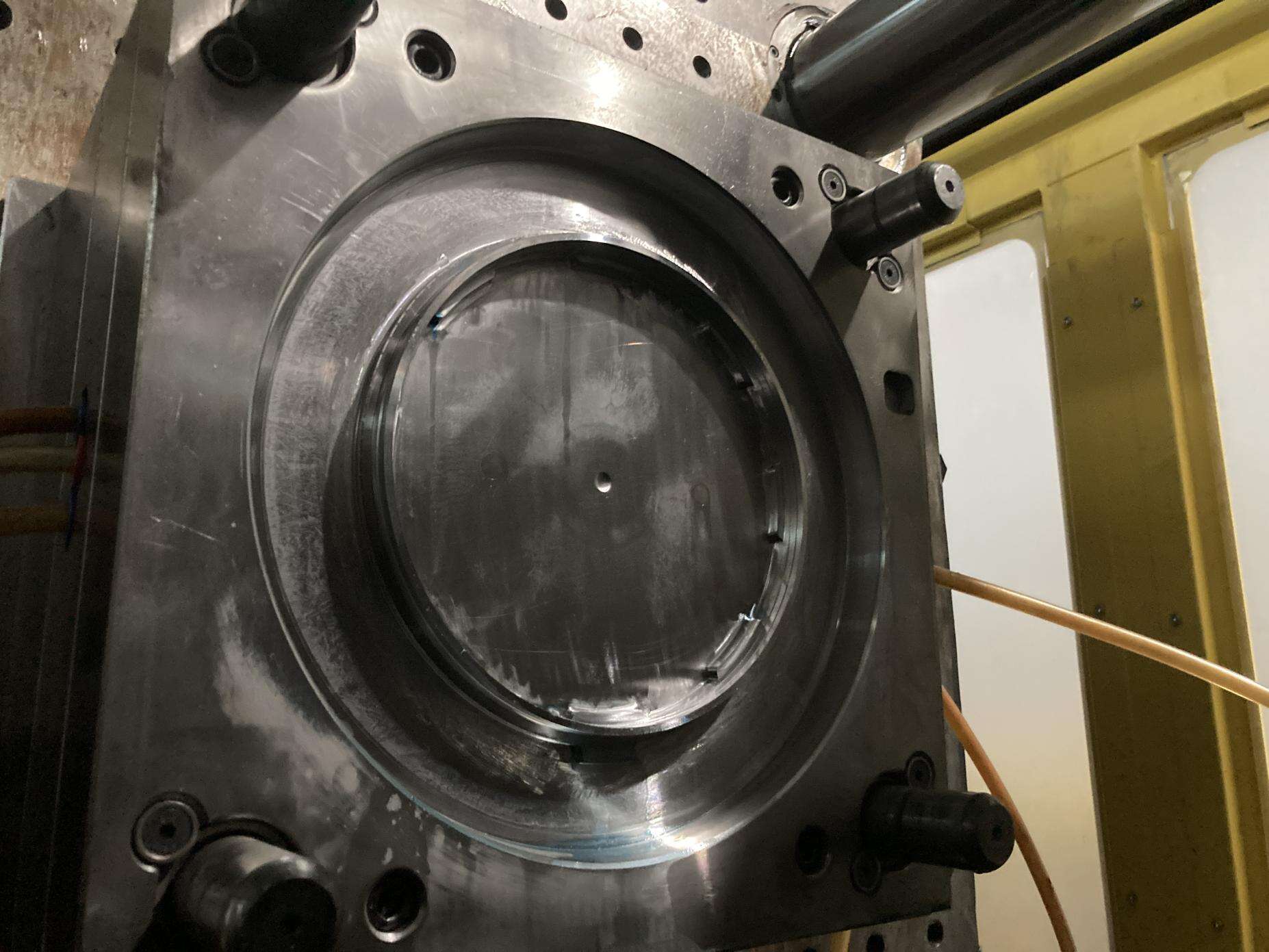

Automatic Plastic Paint Bucket Making Injection Molding Machine Mould

SZ—4800A Injection molding machine.

SCREW DIAMETER (mm) : 75

SCREW LID RATIO (L/D) :21

THEORETICAL SHOT VOLUME (CM3): 1545

SHOT WEIGHT(PS) (g):1406

Description

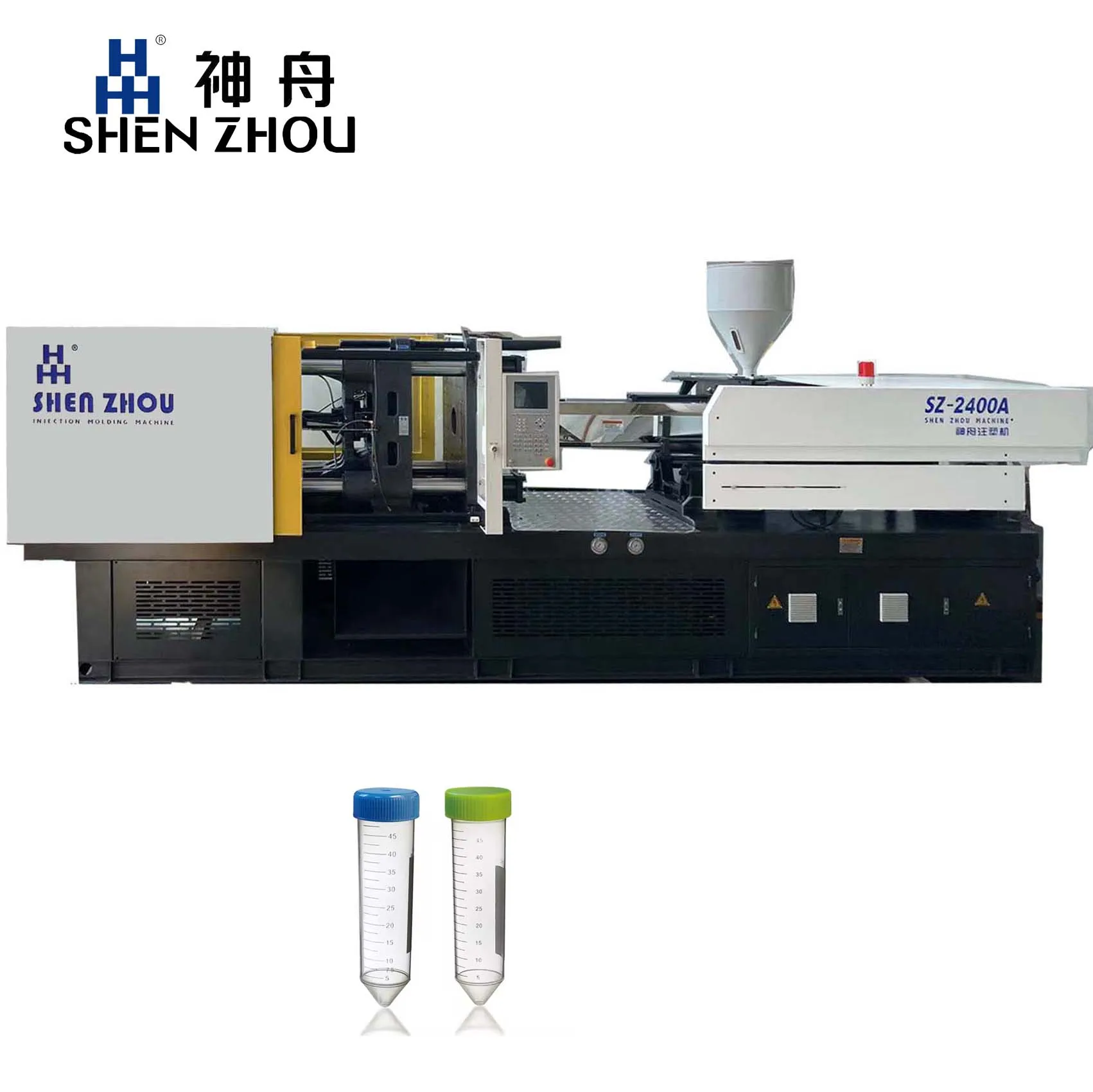

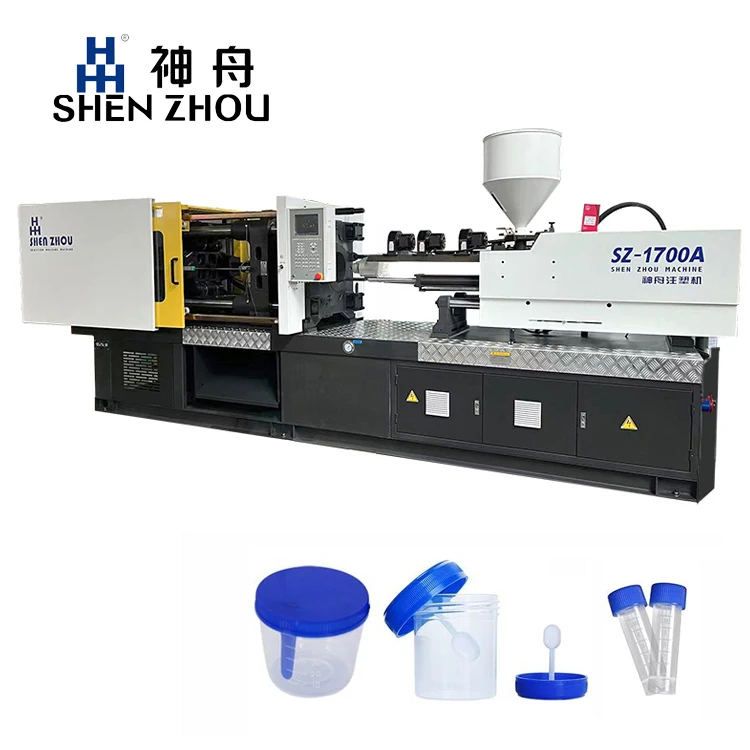

Introducing, the SHENZHOU’s Automatic Plastic Paint Bucket Making Injection Molding Machine Mould, a cutting-edge solution for manufacturing high-quality plastic paint buckets with ease and efficiency. This innovative machine is designed to streamline the production process, reducing labor costs and increasing productivity.

Crafted with precision and durability in mind, the SHENZHOU’s Automatic Plastic Paint Bucket Making Injection Molding Machine Mould is built to last. The sturdy construction ensures long-lasting performance, making it a reliable investment for your business. With its user-friendly interface, this machine is easy to operate, allowing for seamless operation and minimal downtime.

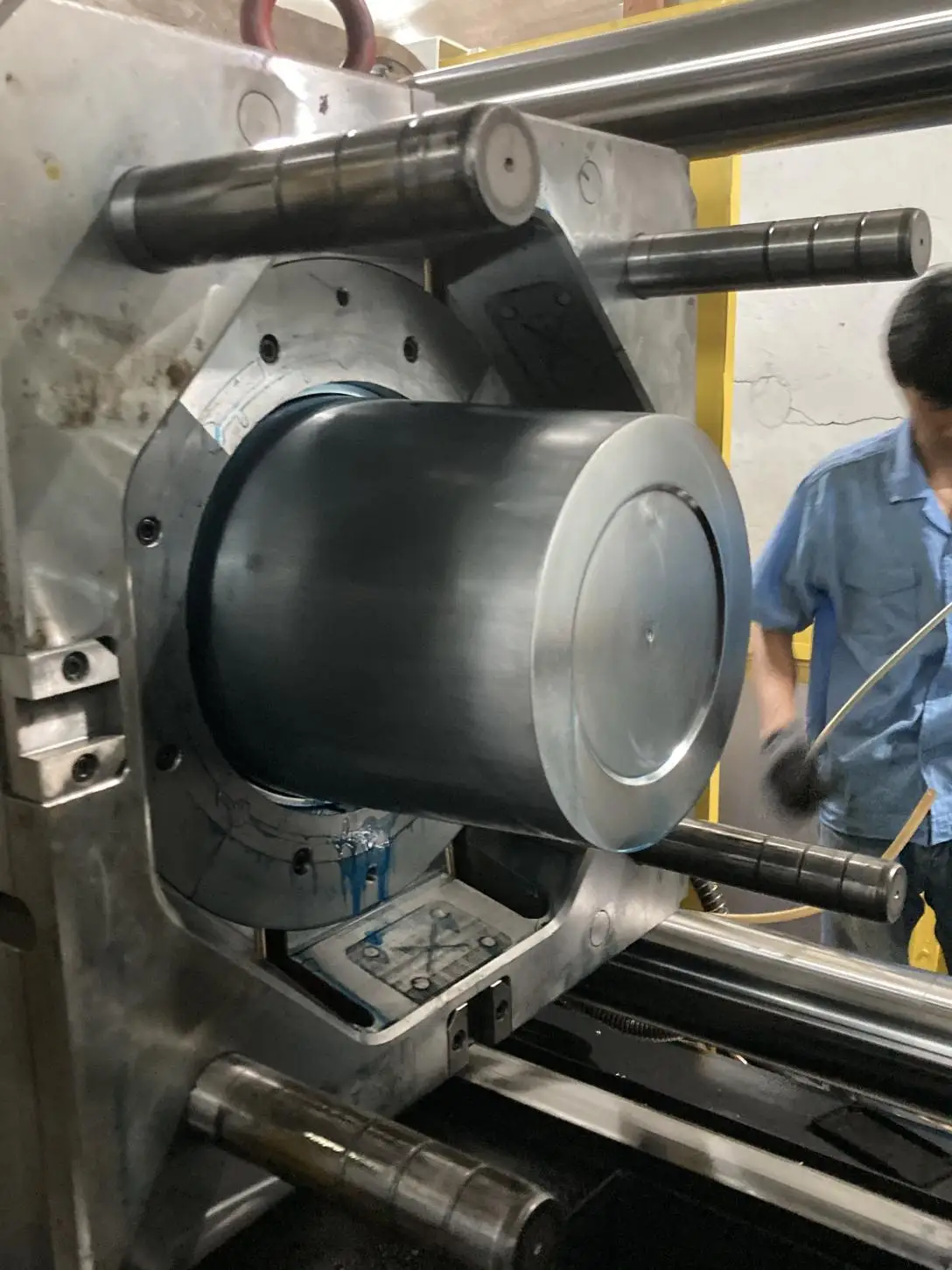

Equipped with advanced technology, the SHENZHOU’s Automatic Plastic Paint Bucket Making Injection Molding Machine Mould offers precise molding capabilities, producing paint buckets that meet industry standards for quality and consistency. The automation feature of this machine eliminates the need for manual intervention, ensuring a smooth and efficient production process.

Whether you are a small business looking to expand your product line or a large-scale manufacturer seeking to increase output, the SHENZHOU’s Automatic Plastic Paint Bucket Making Injection Molding Machine Mould is the ideal solution for your needs. With its high-speed operation and high production capacity, this machine can meet the demands of any production environment, delivering superior results every time.

In addition to its impressive performance, the SHENZHOU’s Automatic Plastic Paint Bucket Making Injection Molding Machine Mould is also designed with safety in mind. The machine is equipped with safety features that protect operators and prevent accidents, giving you peace of mind while maximizing productivity.

With its reliable performance, user-friendly design, and high-quality results, the SHENZHOU’s Automatic Plastic Paint Bucket Making Injection Molding Machine Mould is a must-have for any business looking to optimize their production process. Invest in this top-of-the-line machine today and experience the difference it can make in your manufacturing operations

ITEM |

UNIT |

SZ—3000A |

||

SCREW DIAMETER |

mm |

60 |

65 |

70 |

SCREW LID RATIO |

L/D |

22.7 |

21 |

19.5 |

THEORETICAL SHOT VOLUME |

CM3 |

848 |

995 |

1154 |

SHOT WEIGHT - PS |

g |

772 |

905 |

1050 |

INJECTION PRESSURE |

Mpa |

207 |

176 |

152 |

THEORETICAL INJECTION RATE - PS |

g/s |

241 |

283 |

328 |

PLASTICISING CAPACITY |

g/s |

35.2 |

43.3 |

51.8 |

SCREW TORQUE |

N/m |

2530 |

||

MAX. SCREW ROTATE SPEED |

r/min |

150 |

||

INJECTION STROKE |

mm |

300 |

||

MAX. CLAMPING FORCEK |

KN |

3000 |

||

MAX. OPENING STROKE |

mm |

590 |

||

SPACE BETWEEN TIE BARS |

mm |

610×610 |

||

MOULD HEIGHT |

mm |

220-630 |

||

MAX. DAYLIGHT |

mm |

1220 |

||

EJECTOR FORCE |

KN |

70.6 |

||

EJECTOR STROKE |

mm |

150 |

||

EJECTOR QUANTITY |

|

9 |

||

PUMP MOTOR POWER |

KW |

30 |

||

PUMP PRESSURE |

Mpa |

16 |

||

HEATING POWER |

KW |

22 |

||

HEATING ZONE |

|

5 |

||

SIZE |

m |

6.7×1.75×2.25 |

||

NET WEIGHT |

t |

11 |

||

OIL TANK CAPACITY |

L |

560 |

||

INTERNATIONAL DESIGNATION |

|

3000—1750 |

||

1: Are you a trading company or a manufactory

We are a manufactory, we supply the factory price'' with good quality, welcome to visit

2:Do you have QC or any safety standards for your plastic injection molding machine

Yes, we have established a highly strict quality control department to guanrantee good quality

3:Why choose our plastic injection molding machine

High quality with competitive price

4:How about quality control in your factory

"Quality is first, Customers are friends"