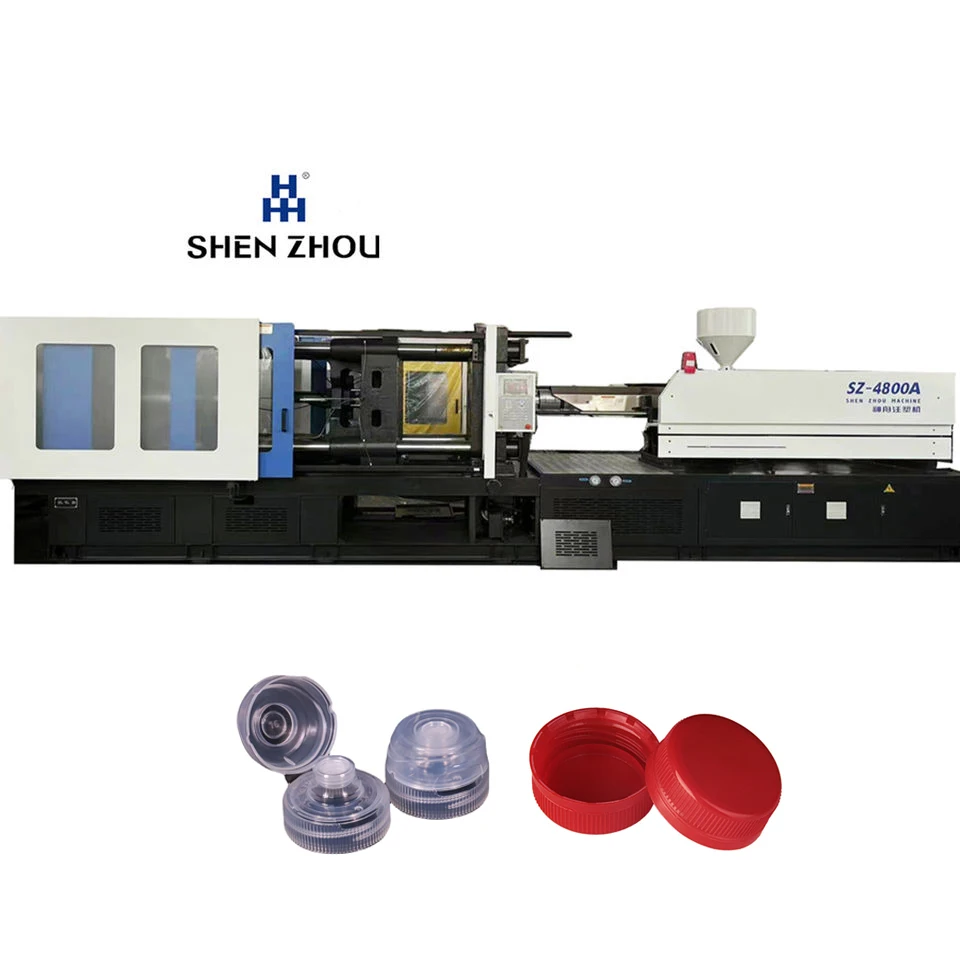

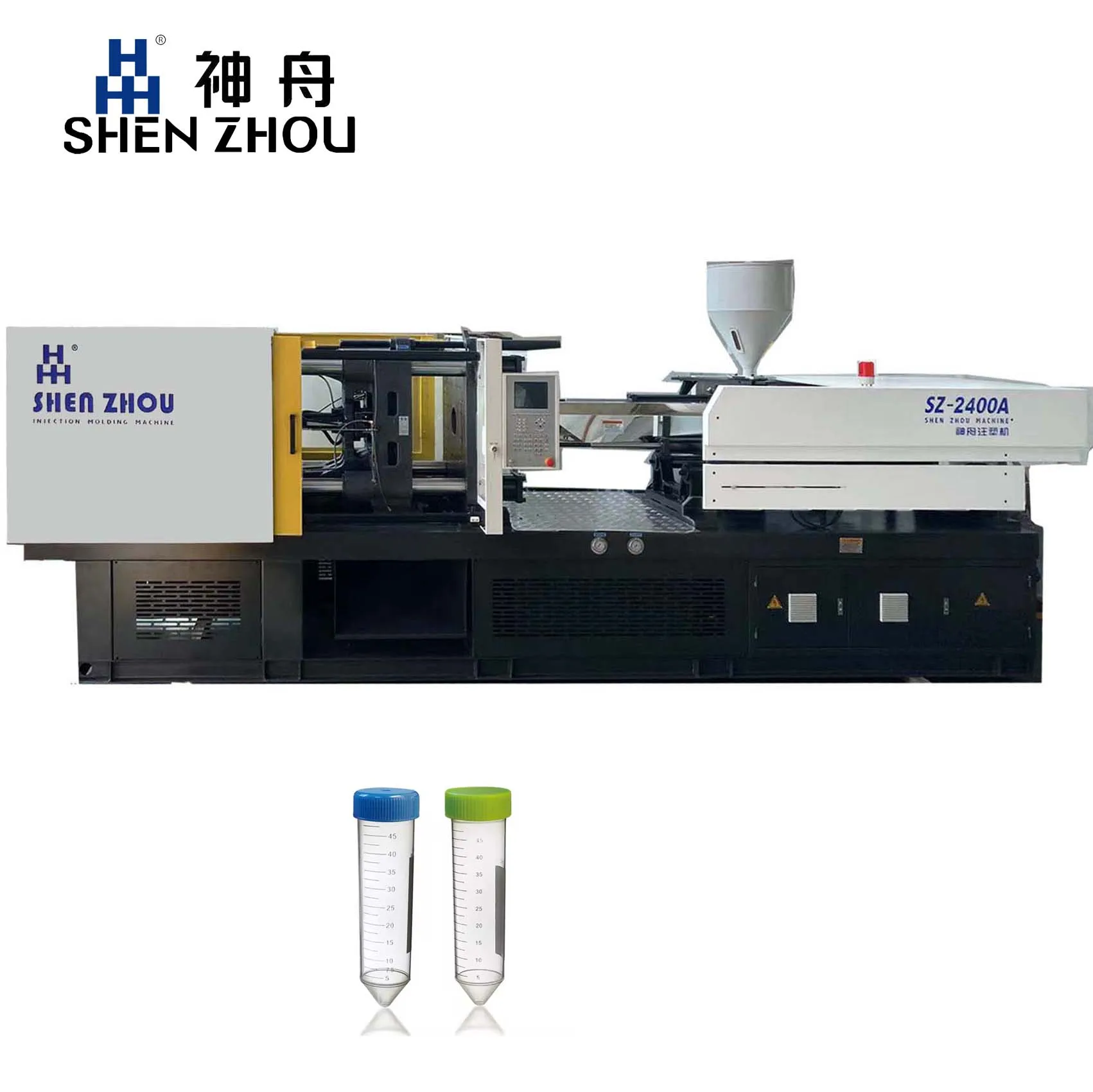

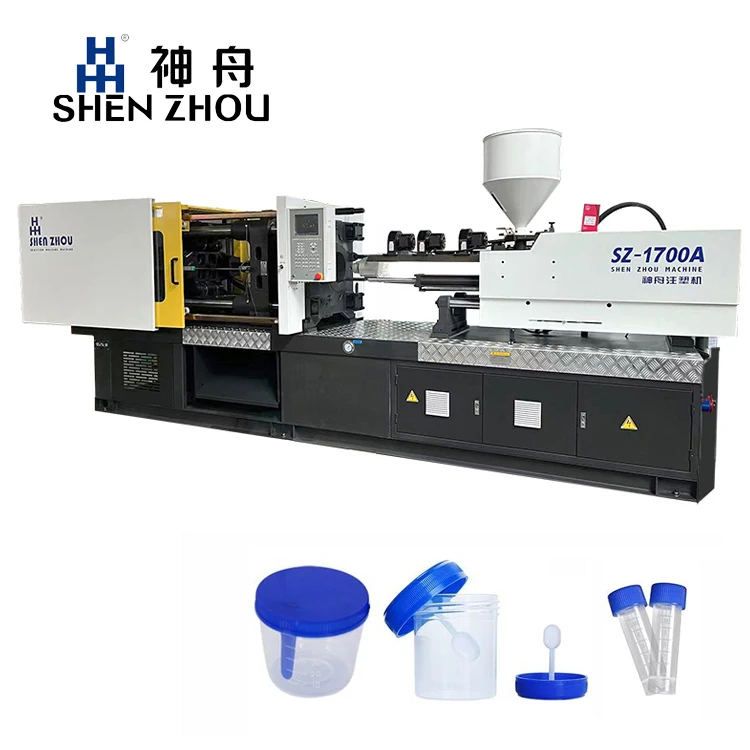

Full Automatic Pet Preform Plastic Bottle Cap Making Water Bottle Capping Injection Machine

Description

The SHENZHOU’s Full Automatic Pet Preform Plastic Bottle Cap Making Water Bottle Capping Injection Machine is a high-quality and reliable machine that is perfect for businesses looking to streamline their bottle cap production process. This machine is designed to be fully automatic, meaning that it can work efficiently and effectively without the need for constant supervision.

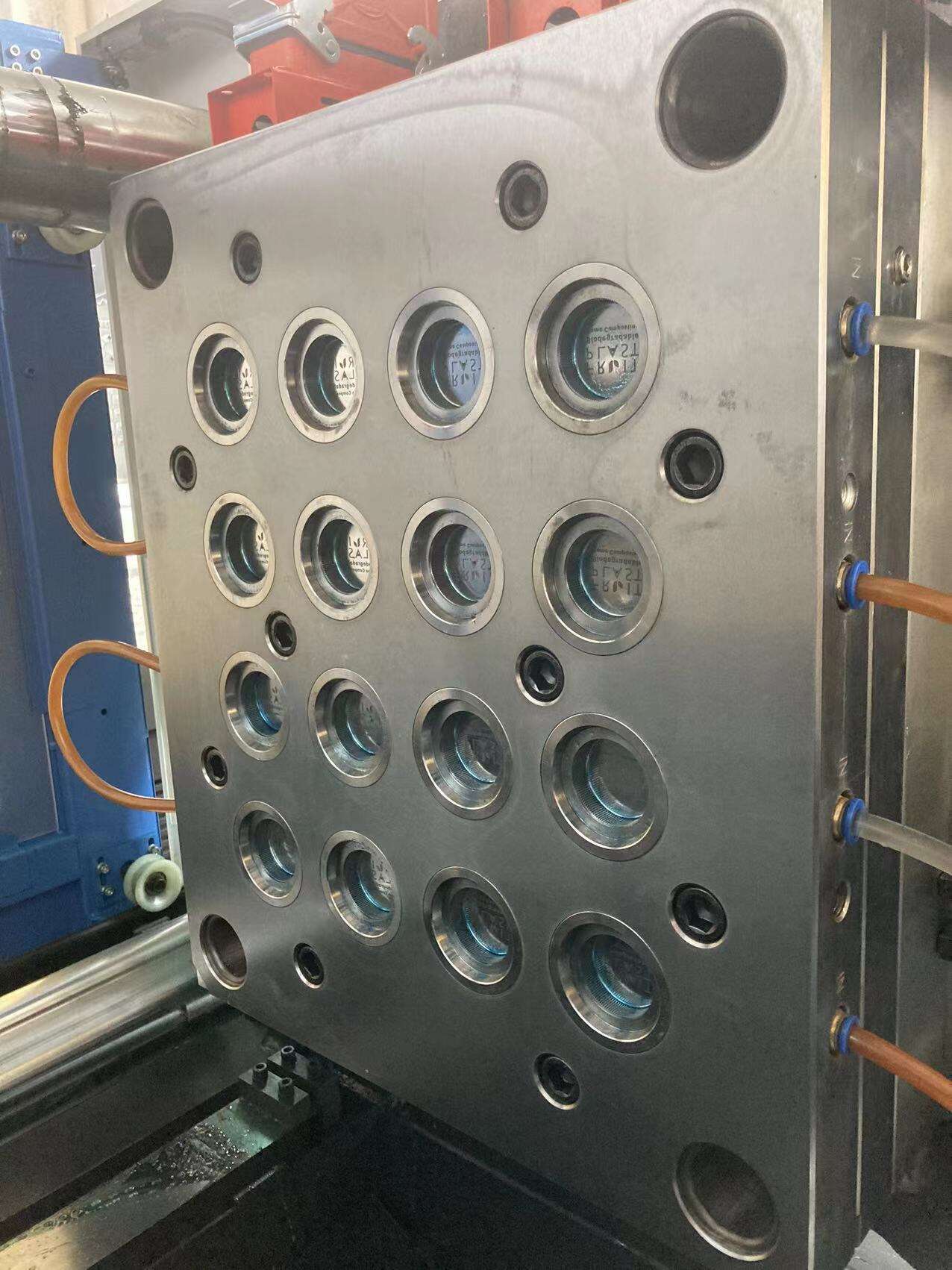

With this machine, you can produce high-quality pet preform plastic bottle caps quickly and easily. The injection molding process ensures that each cap is made with precision and accuracy, resulting in a consistent and reliable product every time. This is essential for businesses that need to meet strict quality standards and ensure customer satisfaction.

The SHENZHOU’s Full Automatic Pet Preform Plastic Bottle Cap Making Water Bottle Capping Injection Machine is also incredibly versatile. It can be used to produce a wide range of bottle cap sizes and styles, making it ideal for businesses that need to produce caps for different types of bottles. Whether you need a small cap for a water bottle or a larger cap for a soda bottle, this machine can handle it all with ease.

One of the standout features of this machine is its water bottle capping capabilities. With its advanced technology and precision engineering, this machine can cap water bottles quickly and securely. This is essential for businesses that need to produce large quantities of water bottles quickly and efficiently.

In addition to its impressive capabilities, the SHENZHOU’s Full Automatic Pet Preform Plastic Bottle Cap Making Water Bottle Capping Injection Machine is also incredibly easy to use. Its user-friendly interface makes it simple for operators to set up and monitor the machine, ensuring that production runs smoothly and efficiently.

The SHENZHOU’s Full Automatic Pet Preform Plastic Bottle Cap Making Water Bottle Capping Injection Machine is a top-of-the-line product that is perfect for businesses looking to streamline their bottle cap production process. With its advanced technology, versatility, and ease of use, this machine is a must-have for any business that needs to produce high-quality bottle caps quickly and efficiently

ITEM |

SZ—4800A |

|||||

SCREW DIAMETER |

mm |

70 |

75 |

80 |

||

SCREW LID RATIO |

L/D |

22.6 |

21 |

19.7 |

||

SHOT WEIGHT - PS |

g |

1225 |

1406 |

1600 |

||

INJECTION PRESSURE |

Mpa |

201 |

175 |

154 |

||

THEORETICAL INJECTION RATE - PS |

g/s |

370 |

423 |

484 |

||

PLASTICISING CAPACITY |

g/s |

60.4 |

71.4 |

83.7 |

||

SCREW TORQUE |

N/m |

3490 |

||||

MAX. SCREW ROTATE SPEED |

r/min |

150 |

||||

INJECTION STROKE |

mm |

350 |

||||

MAX. CLAMPING FORCE K |

KN |

4800 |

||||

MAX. OPENING STROKE |

mm |

770 |

||||

SPACE BETWEEN TIE BARS |

mm |

760×760 |

||||

MOULD HEIGHT |

mm |

280-790 |

||||

MAX. DAYLIGHT |

mm |

1560 |

||||

EJECTOR FORCE |

KN |

113.4 |

||||

EJECTOR STROKE |

mm |

195 |

||||

EJECTOR QUANTITY |

13 |

|||||

PUMP MOTOR POWER |

KW |

45 |

||||

PUMP PRESSURE |

Mpa |

16 |

||||

HEATING POWER |

KW |

28 |

||||

HEATING ZONE |

5 |

|||||

SIZE |

m |

7.5×2.1×2.45 |

||||

NET WEIGHT |

t |

20 |

||||

OIL TANK CAPACITY |

L |

850 |

||||

INTERNATIONAL DESIGNATION |

4800—2710 |

|||||

A: Industry and Trade Integration, we supply the factory price with good quality, welcome to visit

2. Q:How does your factory do regarding quality control

A:"Quality is priority. We always attach great importance to quality controlling from the very beginning to the very end and we have a dedicated quality control department

3. Q:What are your normal lead times

A:Our company typical lead times range from 25-35days after receipt of order. We also have independent venues and engineers to deal with more urgent orders, which can be shipped within 2 weeks

4. Q:About the price

A:We will estimate the cost and provide you with the best price. We can guarantee you the best product quality and after-sales service at the same price. Old customers will enjoy more price concessions

5. Q:How is your machine different from other businesses

A:We have optimized the overall layout of each part of the machine to make the machine run smoothly and have a longer service life. The fine parts have exclusive marks, which makes it more convenient for customers to replace parts and use

6. Q:Where is your factory located? How can I visit there

A: Our factory is located in Shenzhou Machinery, No. 22 Zhenbei Road, Fenghuang Town, Zhangjiagang City China. All our clients, from home or abroad, are warmly welcome to visit us