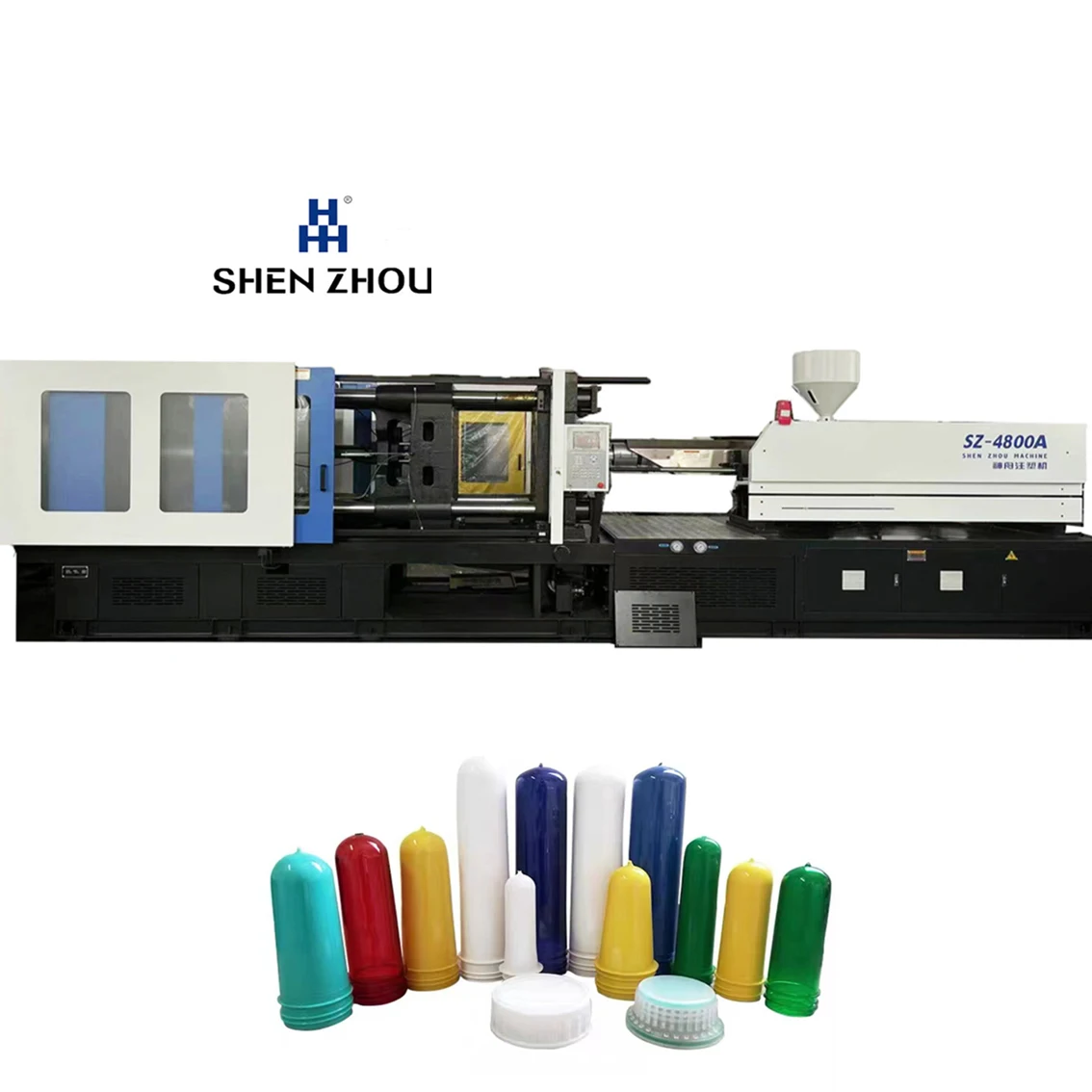

Full Automatic Plastic Cap Making Machines Making Injection Molding/moulding Machine

SZ—4800A Injection molding machine.

SCREW DIAMETER (mm) : 75

SCREW LID RATIO (L/D) :21

THEORETICAL SHOT VOLUME (CM3): 1545

SHOT WEIGHT(PS) (g): 1406

Description

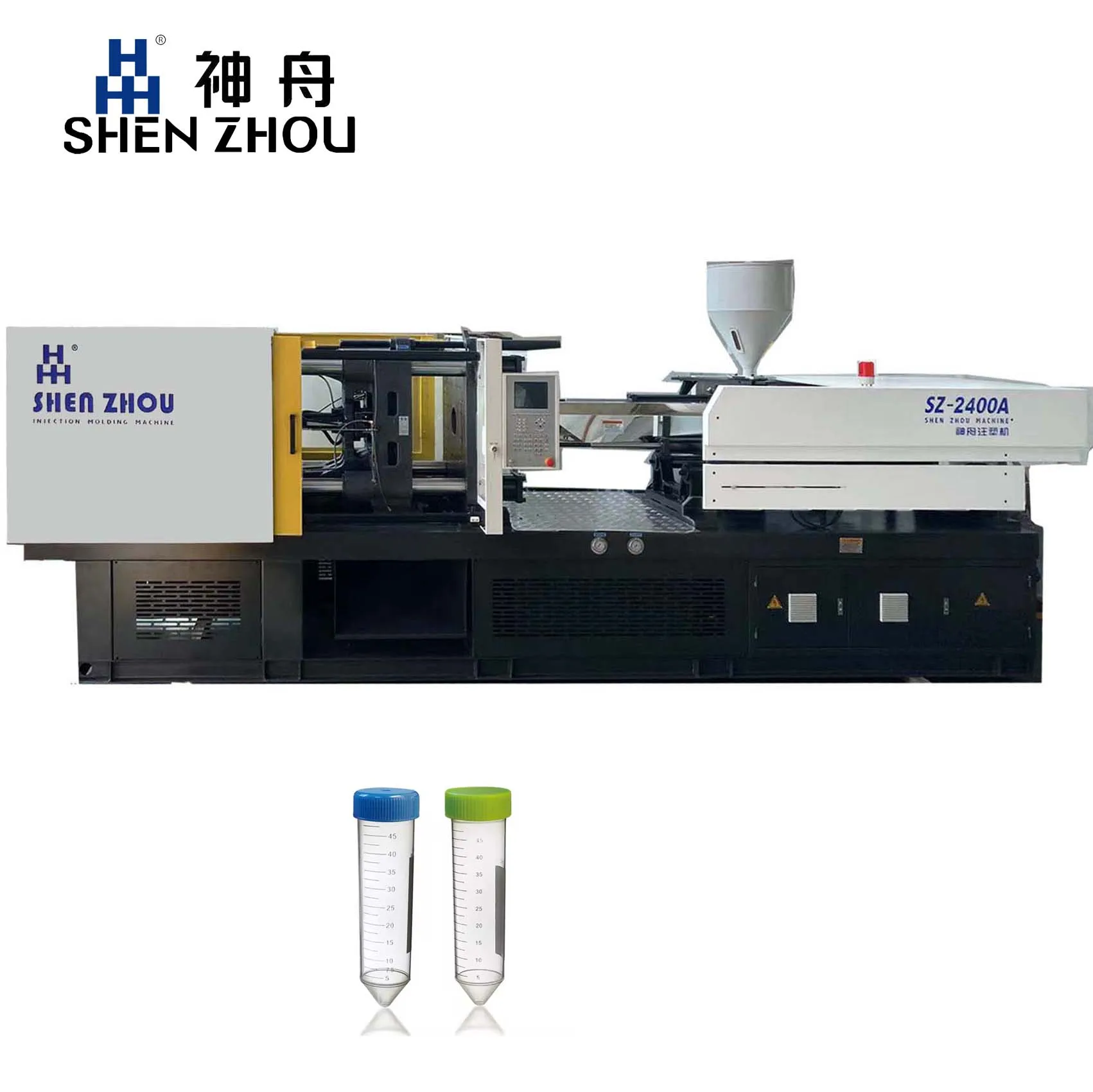

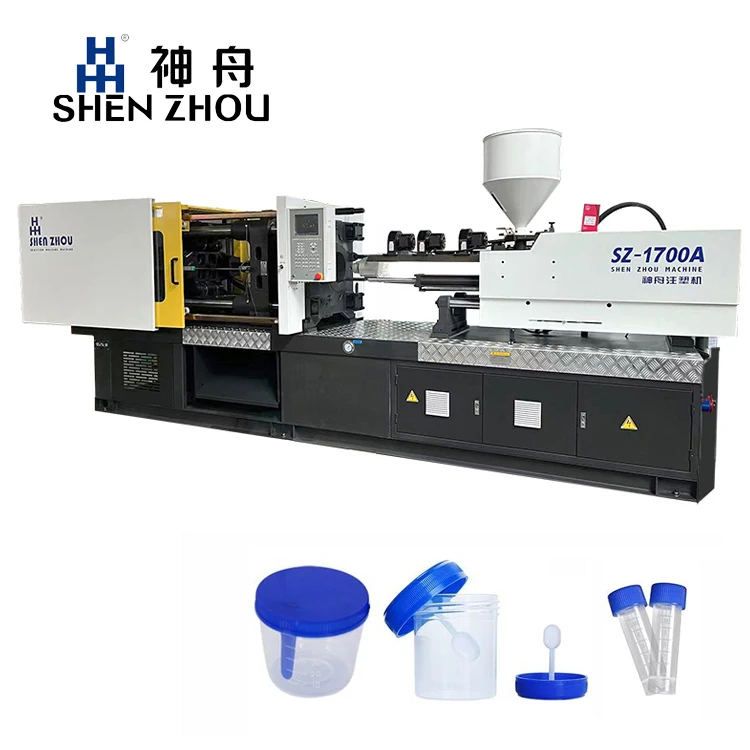

Introducing, the SHENZHOU’s Full Automatic Plastic Cap Making Machine, a top-of-the-line injection molding machine that is revolutionizing the production of plastic caps. This cutting-edge machine is designed to streamline the manufacturing process and increase efficiency, making it the perfect solution for businesses looking to boost their productivity and reduce production costs.

The SHENZHOU’s Plastic Cap Making Machine is a fully automatic machine that is capable of producing high-quality plastic caps with precision and accuracy. This machine is equipped with advanced technology that ensures consistent and reliable performance, allowing for seamless operation and optimal results every time.

One of the key features of the SHENZHOU’s Plastic Cap Making Machine is its injection molding capabilities. This machine uses a state-of-the-art injection molding process to create plastic caps that are durable, uniform, and defect-free. The injection molding process also allows for fast production speeds, making it ideal for businesses with high-volume production needs.

In addition to its injection molding capabilities, the SHENZHOU’s Plastic Cap Making Machine also offers a range of features that enhance its performance and usability. This machine is equipped with a user-friendly control panel that allows for easy operation and monitoring of the production process. It also has a high-speed cooling system that ensures rapid cooling of the plastic caps, allowing for quick cycle times and increased production efficiency.

The SHENZHOU’s Plastic Cap Making Machine is built to last, with a durable construction and high-quality components that ensure long-lasting performance. This machine is also easy to maintain, with simple cleaning and maintenance procedures that help to keep it running smoothly and efficiently.

The SHENZHOU’s Full Automatic Plastic Cap Making Machine is a reliable and efficient solution for businesses looking to improve their plastic cap production process. With its advanced technology, high-quality construction, and user-friendly design, this machine is a smart investment for businesses looking to stay ahead of the competition and maximize their production capabilities. Upgrade to the SHENZHOU’s Plastic Cap Making Machine today and experience the benefits of top-quality plastic cap production

We can provide from 200tons to 550 tons, shot weight from 1225 to 1600 tons injection molding machine for making different washing basin

washing basin molding machine technical specification

Screw diameter |

mm |

70 |

75 |

80 |

Screw L/D ratio |

L/D |

22.6 |

21 |

19.7 |

Shot weight |

gram |

1225 |

1406 |

1600 |

Injection capacity |

cm3 |

1346 |

1545 |

1758 |

Injection pressure |

Mpa |

201 |

175 |

154 |

Theoretical injection rate |

g/s |

370 |

423 |

484 |

Plastic capacity |

g/s |

60.4 |

71.4 |

83.7 |

Injection stroke |

mm |

350 |

||

Screw torque |

N/m |

3490 |

||

Max screw rotate speed |

r/min |

150 |

||

Clamping force |

Ton |

480 |

||

Opening stroke |

mm |

770 |

||

Space between tie bars |

mm |

760×760 |

||

Mould height |

mm |

280~790 |

||

Max daylight |

mm |

1560 |

||

Ejector force |

ton |

11.34 |

||

Ejector stroke |

mm |

195 |

||

Ejector quantity |

|

13 |

||

Oil pump motor |

kw |

45 |

||

Pump pressure |

Mpa |

16 |

||

Heating power |

kw |

28 |

||

Machine size |

M |

7.5*2.1*2.45 |

||

Machine weight |

ton |

20 |

||

Oil tank capacity |

L |

850 |

||

International designation |

|

4800-2710 |

||

Products details :

We have a professional and experience QC team, make sure good quality of every component of machine. All of machines are assembly by our 10 years experienced workers