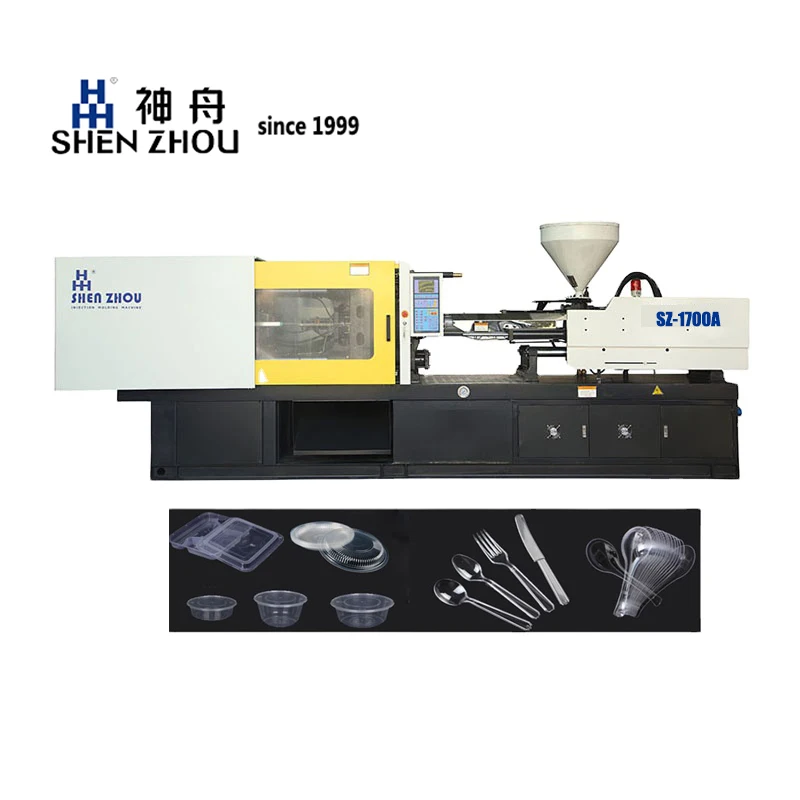

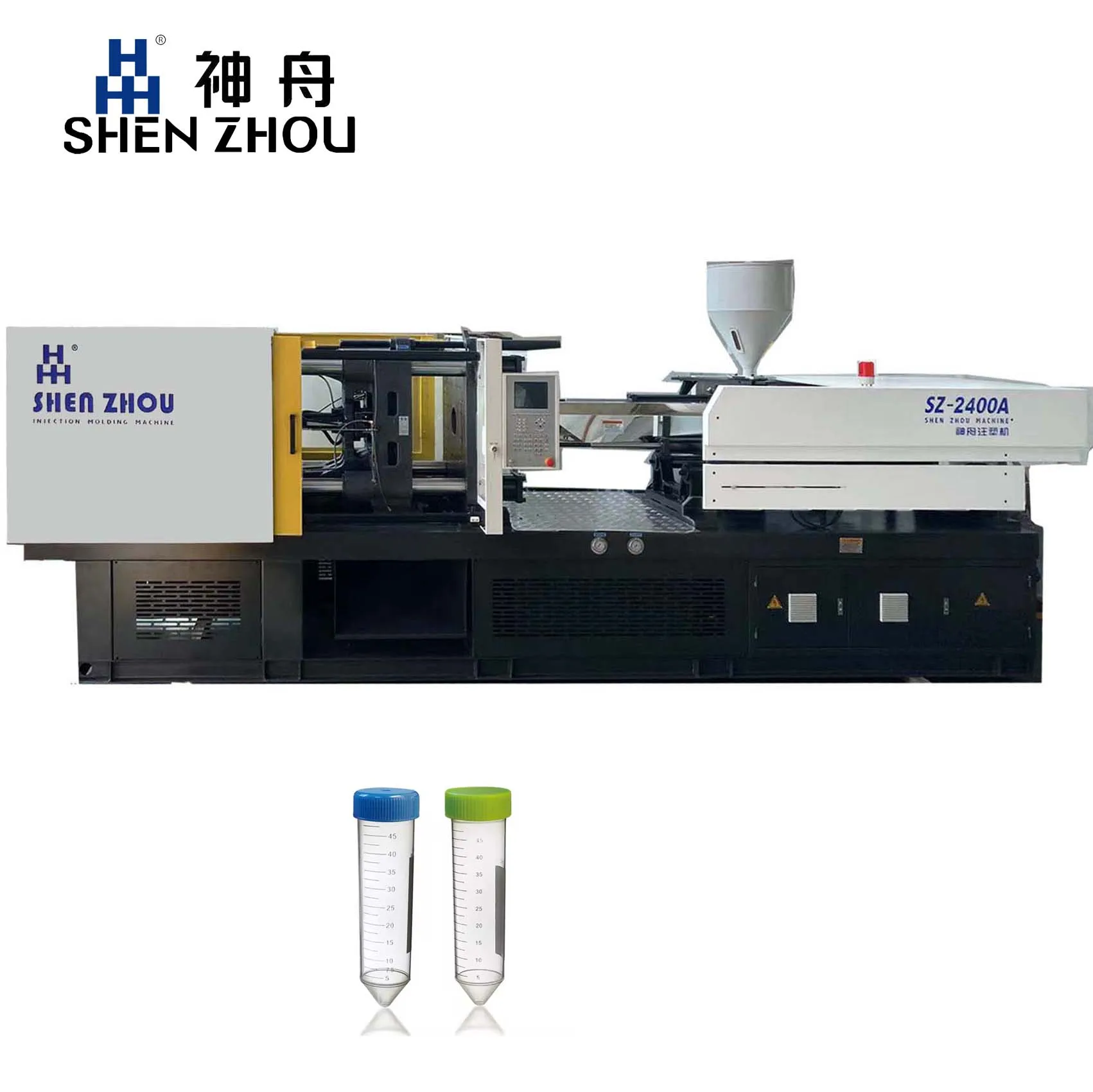

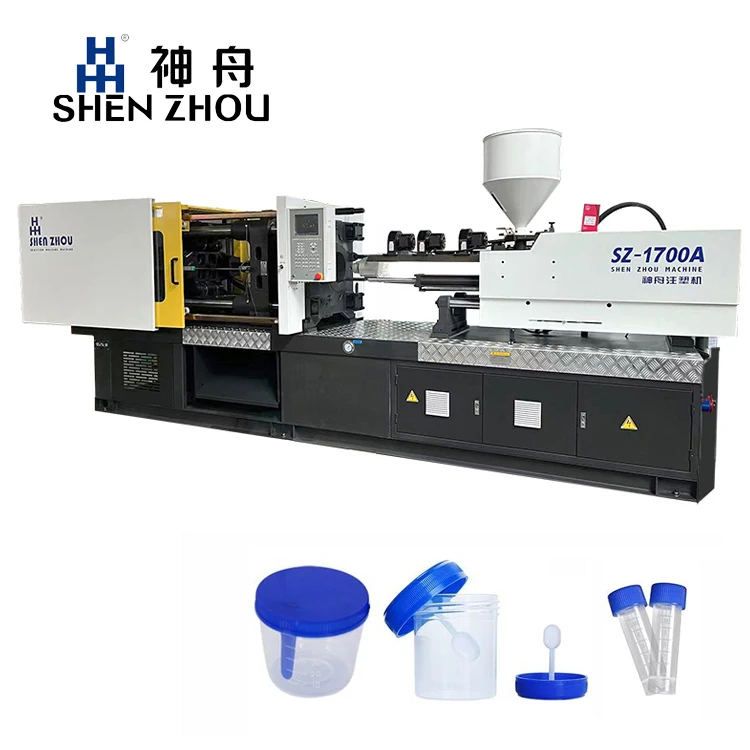

Introducing, the SHENZHOU’s High Speed Plastic Thin Wall Container Making Injection Molding Machine - the ultimate solution for your manufacturing needs. This advanced machine is designed to produce thin wall containers with precision and efficiency, making it the ideal choice for industries requiring high-speed production.

The SHENZHOU’s Injection Molding Machine is equipped with state-of-the-art technology to ensure fast and reliable performance. With a high-speed injection system, this machine can quickly and accurately mold plastic containers with thin walls, resulting in high-quality products every time. The precision control system allows for consistent and uniform production, making it perfect for mass production of containers.

In addition to its speed and accuracy, the SHENZHOU’s Injection Molding Machine is also designed for durability and longevity. Made from high-quality materials, this machine is built to last and can withstand the rigors of continuous use. With proper maintenance, you can count on this machine to deliver consistent results for years to come.

One of the standout features of the SHENZHOU’s Injection Molding Machine is its user-friendly design. With intuitive controls and easy-to-follow instructions, operating this machine is a breeze. Whether you are a seasoned professional or new to the industry, you will find it easy to set up, operate, and maintain this machine.

When it comes to price, the SHENZHOU’s Injection Molding Machine offers excellent value for money. With competitive pricing and high-quality performance, this machine is a smart investment for any manufacturing business looking to increase production efficiency and output.

The SHENZHOU’s High Speed Plastic Thin Wall Container Making Injection Molding Machine is a top-of-the-line product that delivers exceptional results. With its fast production speed, precision molding capabilities, and user-friendly design, this machine is a must-have for any business in need of high-quality plastic container production. Invest in the SHENZHOU’s Injection Molding Machine today and experience the difference it can make for your business

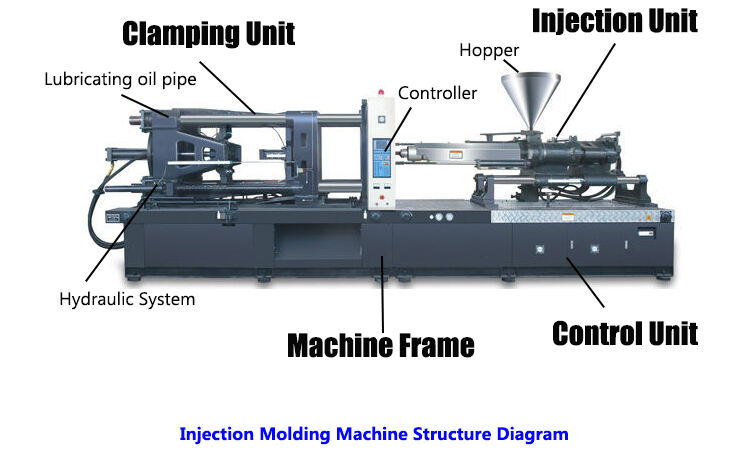

Clamping Unit

âNew type 5-point toggle device of stable movement curve, gentle shock

âSuperior mould platen to ensure no out of shape if high-pressure clamping

âHard chrome plated high tensile strength tie bars made of superior alloy

âWear-resistant guide for moving platen

âTransducer control clamping stroke

âMany step control for speed and pressure of clamping and opening

âEiection device offer dwell, single, more, vibration function

âLow pressure mould protection function

âHydraulic mould height adjustment with rough and fine operation

âMechanical and electrical dual safety interlock

âAutomatic centralized lubrication system with far pressure detector

Injection Unit

âNitrided screw and barrel with long service life

âSmelted screw with big L/D ratio with good plasticizing and color-fixing

âDouble injection cylinder of compact construction and good equilibrant

âTransducer control injection stroke

âThe speed of low speed and large torque hydraulic motor can be adjusted

âScrew back pressure control and nozzle anti-leakage control movable hopper for easy remove material

âInjection-catriage can be used for slacking, re-feedingor fixed-feeding

âSpeed and pressure of injecting and holding controlled by time or position

âEquipped with reverse device to be easily removed and cleaned

Hydraulic System

âProportional pressure and flow control with fine adjustment and precision

âKnow-how manifold design, compact, reasonable and fast respond

âImported world famous hydraulic valves

âImported world famous hydraulic sealing rings

âImported technology hydraulic hose and fittings

âLow noise hydraulic system

âPrecision oil filter and oil cooler

Control System

âAdopt PLC control system

âHigh reliability and strong anti-interference ability

âComplete functions and strong applicability

âUser-friendly Design. It is easy to operate and is well received by engineering and technical personnel

âPLC replaces wiring logic with storage logic, which greatly shortens the design and construction cycle of the control system. It is easy to maintain, easy to transform, and suitable for many kinds of production occasions

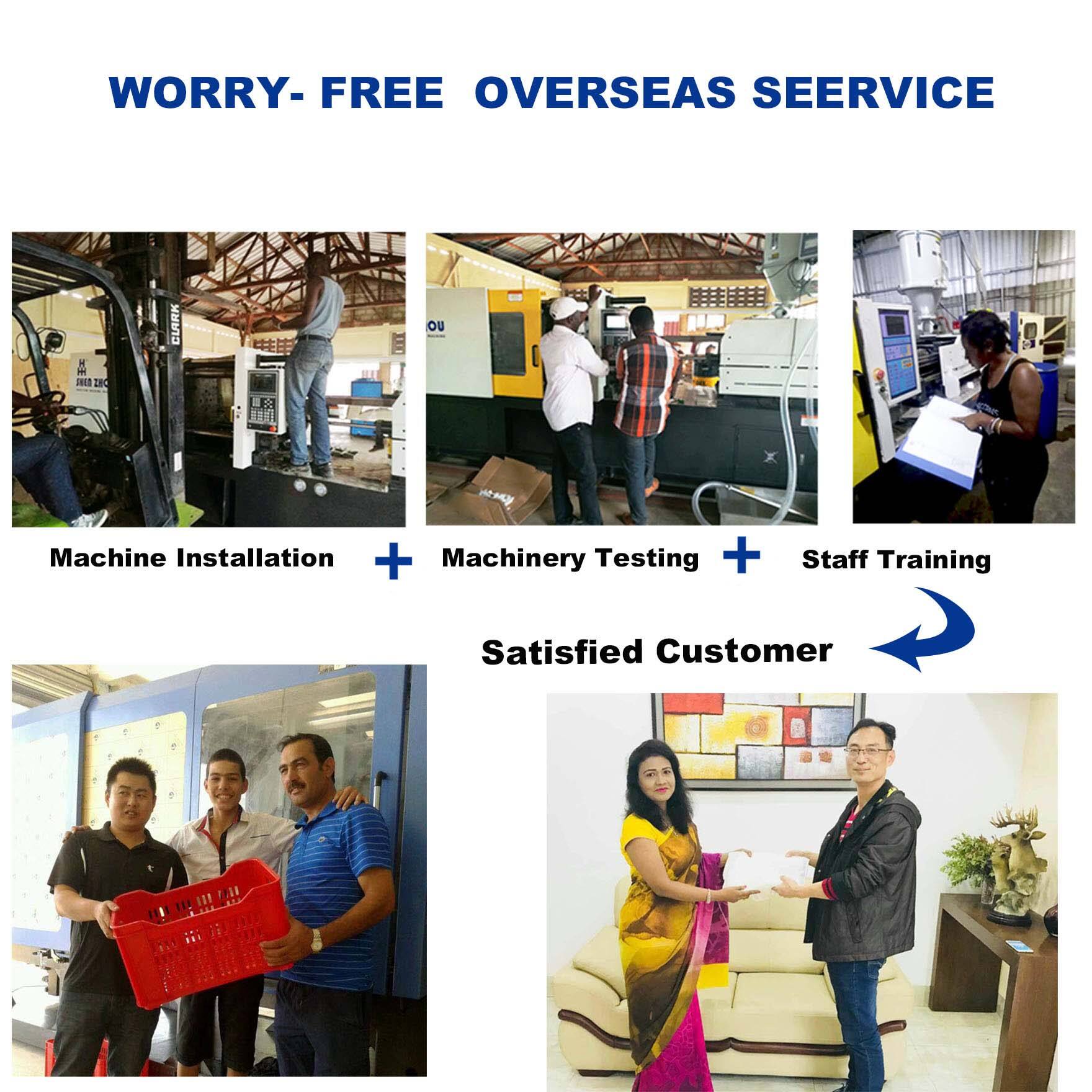

1. 20 years of professional injection molding machine and mold manufacturer, excellent quality, honest management

2. Continuous technological innovation, optimized product structure, longer service life

3. Lifetime maintenance of the product, 24 hours after-sales service

4. The main components are all world-renowned brands

5. Dedicated quality control department

6. Ex-factory price

ONE-STOP Injection Molding Engineering Solution

1.

Supporting service capabilities. From injection molding machines to molds, auxiliary machines, and plastic products, we can achieve turnkey projects; we can help you complete the plant design and quickly build a complete production line

2. Quick response capability. We have after-sales service centers and technical representatives in many places at home and abroad. If your products have any problems, we can solve them in time

3. Comprehensive service capabilities. Customer first! We strictly implement this principle in every aspect of the transaction. For example, during machine R&D and design, the layout of the operating system and circuit is optimized to facilitate the subsequent operation and maintenance of customers. We have always been thinking about problems from the perspective of customers and providing you with the most humane service

Follow us and you will get:

1. Live exploration factory

2. A service team with 20 years of rich experience

3. Auxiliary machines or accessories are free! etc

|

|

|

|

|

|

UNIT |

|

|

|

|

|

SCREW DIAMETER |

mm |

45 |

50 |

55 |

|

|

|

|

SCREW L/D RATIO |

L/D |

23.3 |

21 |

19.1 |

|

|

|

|

Theoretical Shot Volume |

cm^3 |

358 |

442 |

534 |

|

|

|

|

SHOW WEIGHT - PS |

g |

326 |

402 |

486 |

|

|

|

|

INJECTION PRESSURE |

Mpa |

219 |

178 |

147 |

|

|

|

|

THEORETICAL INJECTION RATE - PS |

g/s |

142 |

175 |

212 |

|

|

|

|

PLASTICISING CAPACITY |

g/s |

20.1 |

26.5 |

34.2 |

|

|

|

|

SCREW TORQUE |

N/m |

|

|

|

|

|

MAX. SCREW ROTATE SPEED |

r/min |

|

|

|

|

|

INJECTION STROKE |

mm |

|

|

|

|

|

|

|

|

|

|

ITEM |

UNIT |

|

VALUE |

|

|

|

MAX. CLAMPING FORCE |

KN |

|

1700 |

|

|

|

MAX. OPENING STROKE |

mm |

|

460 |

|

|

|

SPACE BETWEEN TIE BARS |

mm |

|

480*480 |

|

|

|

MOULD HEIGHT |

mm |

|

180-500 |

|

|

|

MAX. DAYLIGHT |

mm |

|

960 |

|

|

|

EJECTOR FORCE |

KN |

|

45.2 |

|

|

|

EJECTOR STROKE |

mm |

|

115 |

|

|

|

EJECTOR QUANTITY |

|

|

5 |

|

|

|

|

|

|

|

|

ITEM |

UNIT |

|

VALUE |

|

|

|

PUMP MOTOR POWER |

kw |

|

15 |

|

|

|

PUMP PRESSURE |

Mpa |

|

16 |

|

|

|

HEATING POWER |

kw |

|

13.6 |

|

|

|

HEATING ZONE |

|

|

4 |

|

|

|

SIZE |

m |

|

5.3*1.35*1.9 |

|

|

|

NET WEIGHT |

t |

|

5.6 |

|

|

|

OIL TANK CAPACITY |

L |

|

420 |

|

|

|

INTERNATIONAL DESIGNATION |

|

|

1700-785 |

|

|

|

SHENZHOU-Since 1999

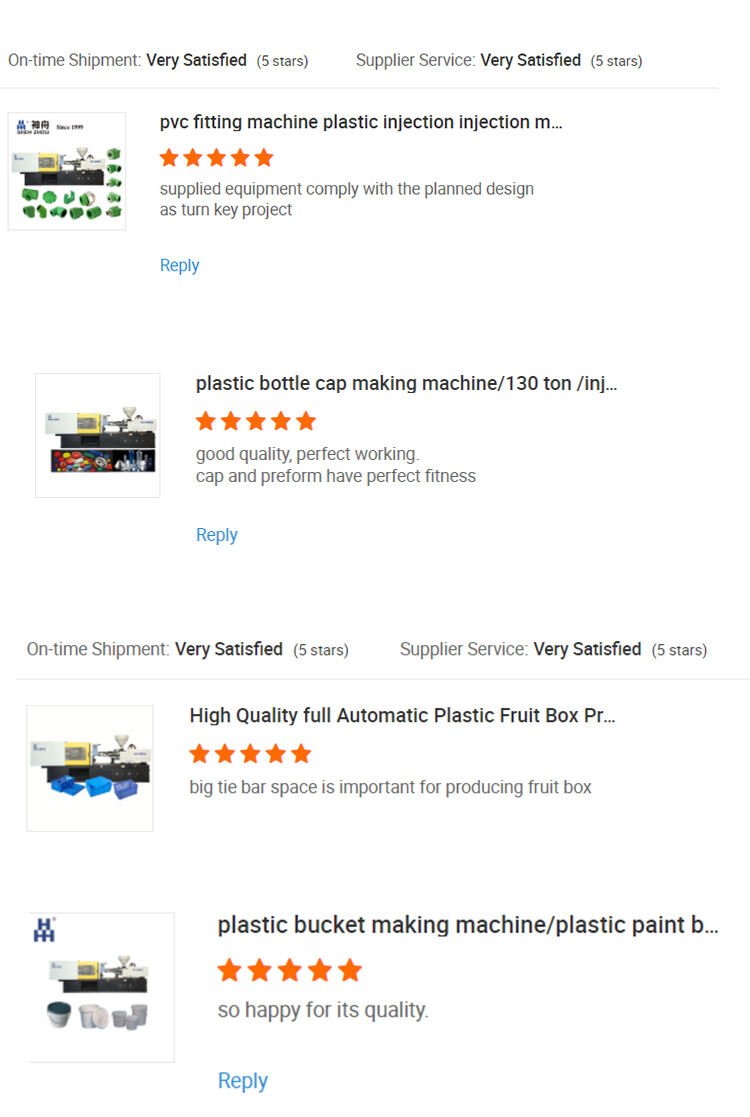

We specialize in manufacturing and exporting injection molding machines, with an injection weight of 60-10000 grams and a clamping force of 95-1600 tons. Using more than 20 years of injection molding machine knowledge and experience, implementing the most modern design and precision manufacturing, using imported famous and high-quality hydraulic, electrical, and sealing parts, we have manufactured the SZ series of fully automatic computerized injection molding machines and their downstream equipment. They are characterized by high quality, high reliability, stable operation and attractive price/performance ratio

Our machines can meet customer needs and profits. Compared with machines in other factories, our machine has larger injection weight, larger opening stroke and larger distance between tie rods. With high-quality and innovative products, excellent productivity, efficient management, perfect technical solutions and services, our machines are sold to more than 20 domestic provinces and cities, and exported to the Middle East, Southeast Asia, Russia, Central Asia, Africa, America, Europe and many more. All our customers have given high praise to our machines and services

Old friend

The client's name is Obed, from Tanzania. He is our old friend. We have been working with him for more than 15 years and we have established a deep friendship. At the beginning, Obed was our ordinary customer. After a period of mutual cooperation and understanding, he has become our technical representative in Tanzania and can provide various technical support to our customers in Tanzania. At the end of 2020, we will have 23 injection molding machines and a large number of molds sent to Tanzania

Large Orders

The order is from Turkmenistan. A customer friend of ours bought 26 injection molding machines of various models and a large number of molds and auxiliary equipment at a time. After receiving the order, we attach great importance to it, speed up the operation of the workshop, and complete the scheduled tasks in advance. The picture shows a customer in Uzbekistan. We have a vast market in this region

Government program

This project is a cooperation project between us and Ethiopian AG pipe fitting company in 2019. Our company started cooperation with Ethiopia long ago. We have delivered more than 15 injection molding machines and more molds to Ethiopia

We will apply lubricating oil and spray anti-rust agent to the products before shipment, prepare enough spare parts, and confirm that they are fully fixed before shipment. We pay attention to details and hope to bring you a better experience

1. Q:Are you a factory or trading company

A: Industry and Trade Integration, we supply the factory price with good quality, welcome to visit

2. Q:How does your factory do regarding quality control

A:"Quality is priority. we always attach great importance to quality controlling from the very beginning to the very end and we have a dedicated quality control department

3. Q:What are your normal lead times

A:Our company typical lead times range from 25-35days after receipt of order. We also have independent venues and engineers to deal with more urgent orders, which can be shipped within 2 weeks

4. Q:About the price

A:We will estimate the cost and provide you with the best price. We can guarantee you the best product quality and after-sales service at the same price. Old customers will enjoy more price concessions

5. Q:How is your machine different from other businesses

A:We have optimized the overall layout of each part of the machine to make the machine run smoothly and have a longer service life. The fine parts have exclusive marks, which makes it more convenient for customers to replace parts and use

6. Q:Where is your factory located? How can I visit thereA: Our factory is located in Shenzhou Machinery, No. 22 Zhenbei Road, Fenghuang Town, Zhangjiagang City China. All our clients, from home or abroad, are warmly welcome to visit us

You are welcome to send us samples, we will customize high-quality machines for you! Best wishes for you