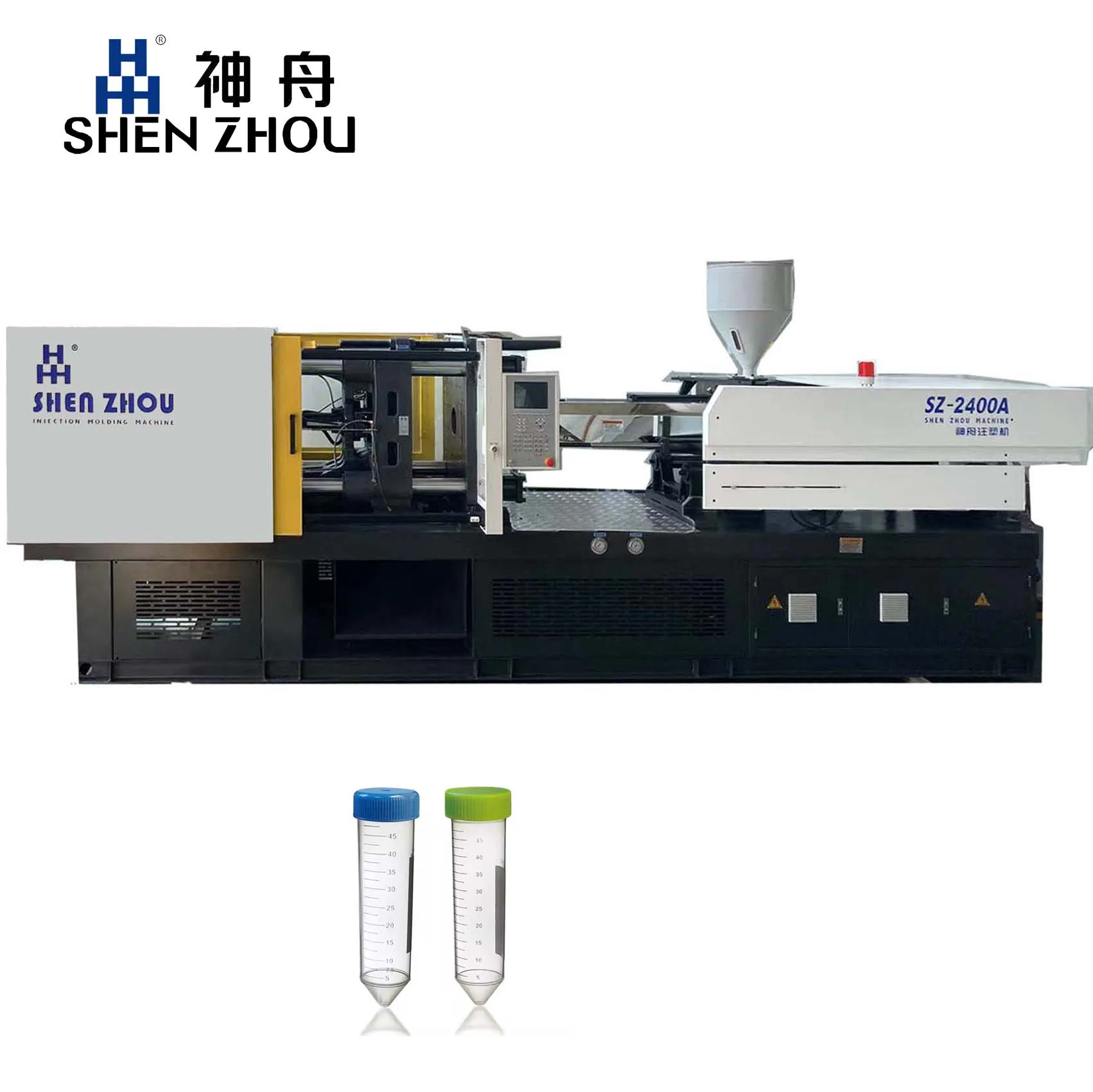

Plastic Factory Direct Sale Centrifuge Tube Tube Bottom Centrifugal Pipe Injection Molding Machine

|

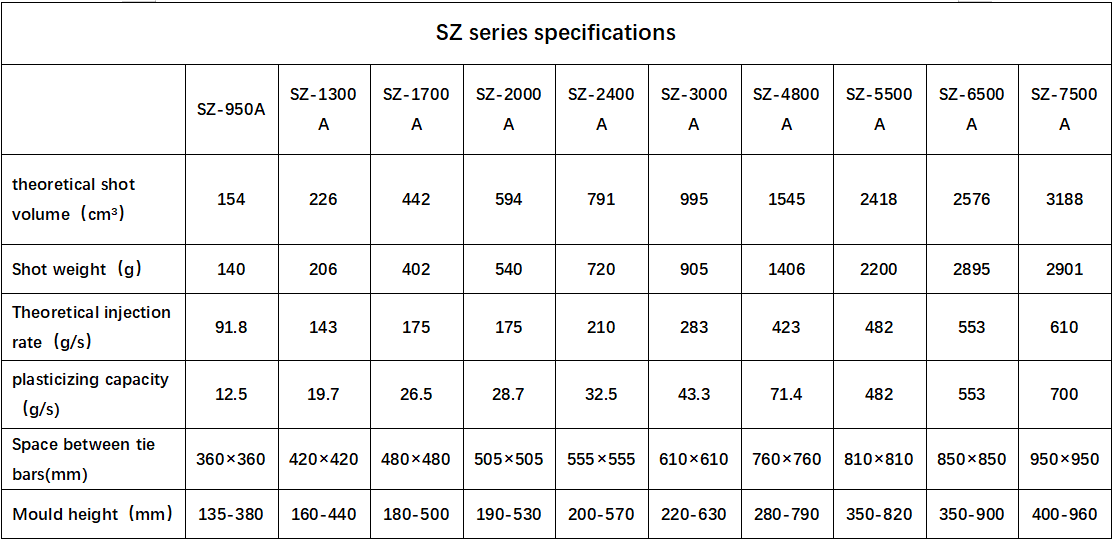

ITEM |

UNIT |

SZ—2400A |

||

|

INJECTION UNIT |

|

|

||

|

SCREW DIAMETER |

mm |

55 |

60 |

65 |

|

SCREW LID RATIO |

L/D |

22.9 |

21 |

19.4 |

|

THEORETICAL SHOT VOLUME |

CM3 |

665 |

791 |

929 |

|

SHOT WEIGHT(PS) |

g |

605 |

720 |

845 |

|

INJECTION PRESSURE |

Mpa |

210 |

176 |

150 |

|

THEORETICAL INJECTION RATE(PS) |

g/s |

176.5 |

210 |

245 |

|

PLASTICISING CAPACITY |

g/s |

26.4 |

32.5 |

40 |

|

SCREW TORQUE |

N.m |

2000 |

||

|

MAX.SCREW ROTATE SPEED |

r/min |

150 |

||

|

INJECTION STROKE |

mm |

280 |

||

Description

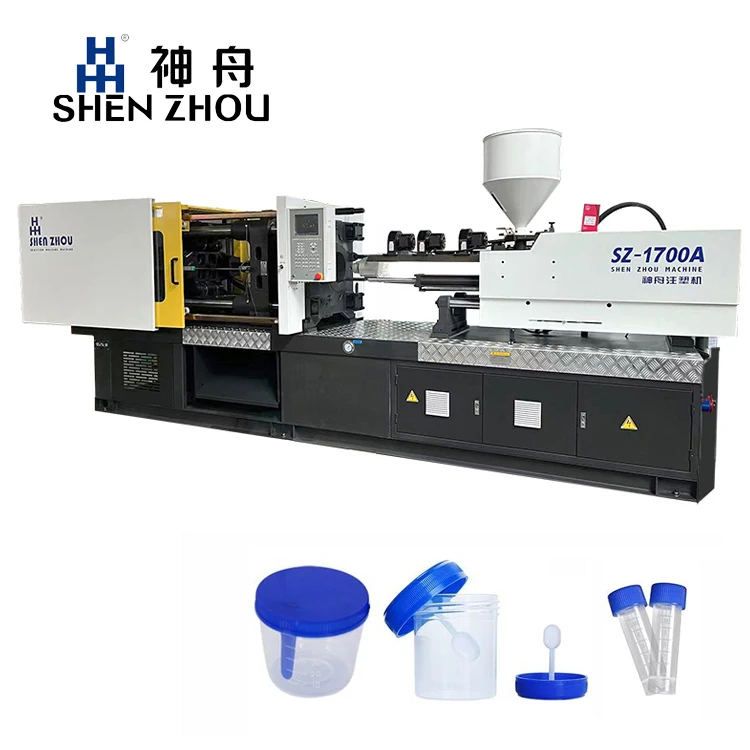

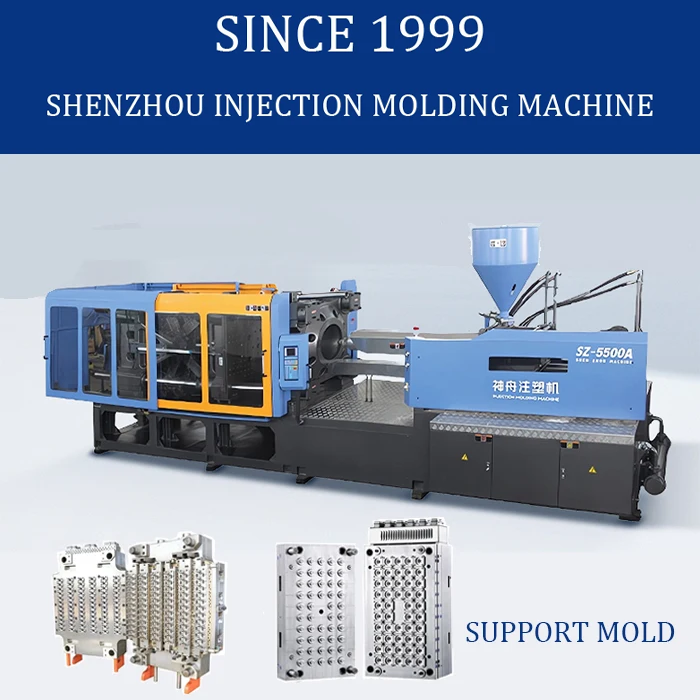

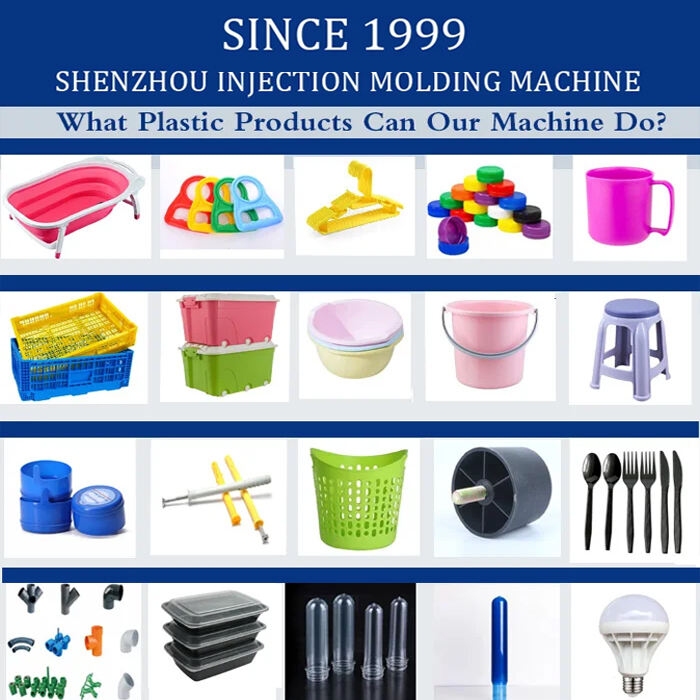

Introducing, the SHENZHOU’s Plastic Factory Direct Sale Centrifuge Tube Tube Bottom Centrifugal Pipe Injection Molding Machine - the ultimate solution for all your plastic manufacturing needs. This cutting-edge machine is designed to streamline the production process and ensure top-quality results every time.

With its advanced technology and precision engineering, the SHENZHOU’s Centrifuge Tube Injection Molding Machine is capable of producing a wide range of plastic products with unmatched speed and efficiency. Whether you're in the medical, automotive, or consumer goods industry, this machine is the perfect choice for manufacturing centrifuge tubes, tube bottoms, or centrifugal pipes.

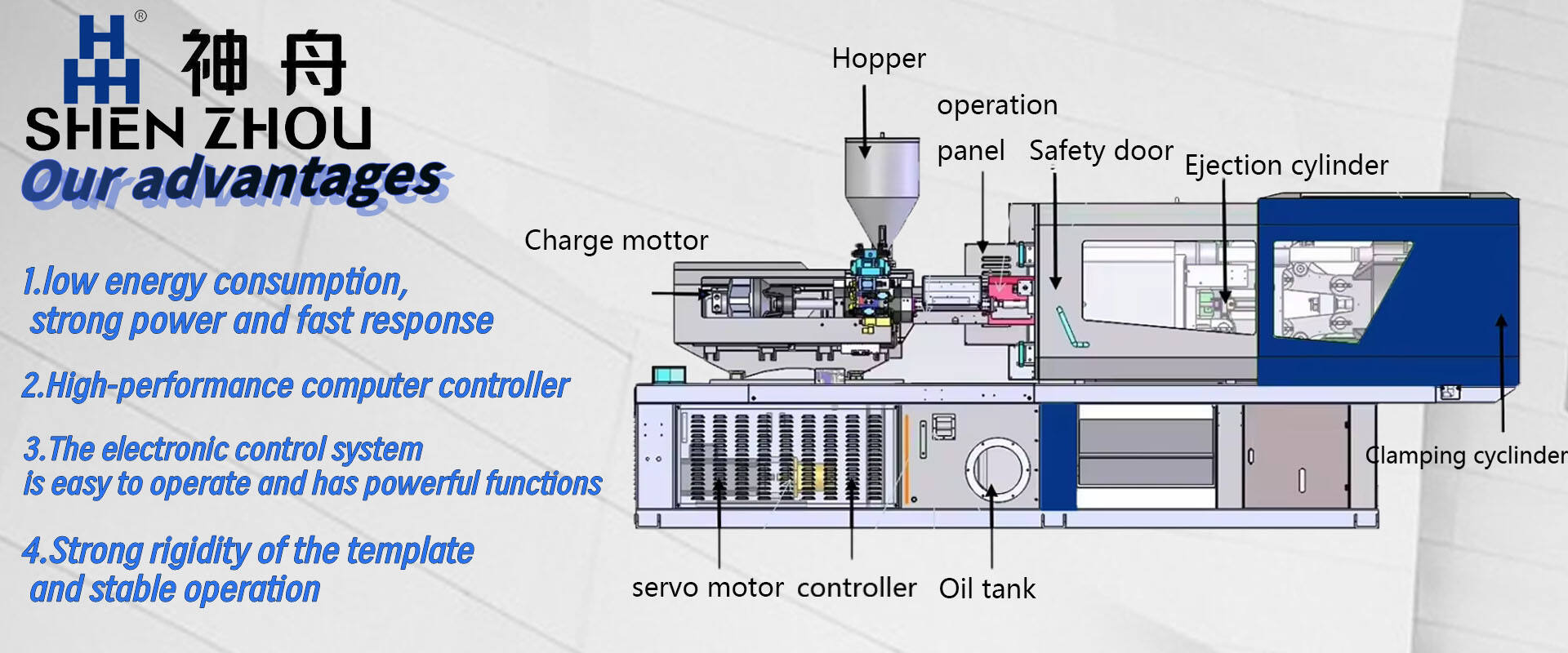

One of the key features of the SHENZHOU’s Injection Molding Machine is its user-friendly design, which makes it easy to operate and adjust according to your specific production requirements. The machine is equipped with a digital control panel that allows you to monitor and control the injection process with precision. This ensures consistent product quality and minimizes waste, saving you time and money in the long run.

In addition to its high performance, the SHENZHOU’s Centrifuge Tube Injection Molding Machine is also built to last. Made from durable materials and with a robust construction, this machine is designed to withstand the rigors of daily use in a factory setting. You can rely on it to deliver consistent results over time, making it a worthwhile investment for your business.

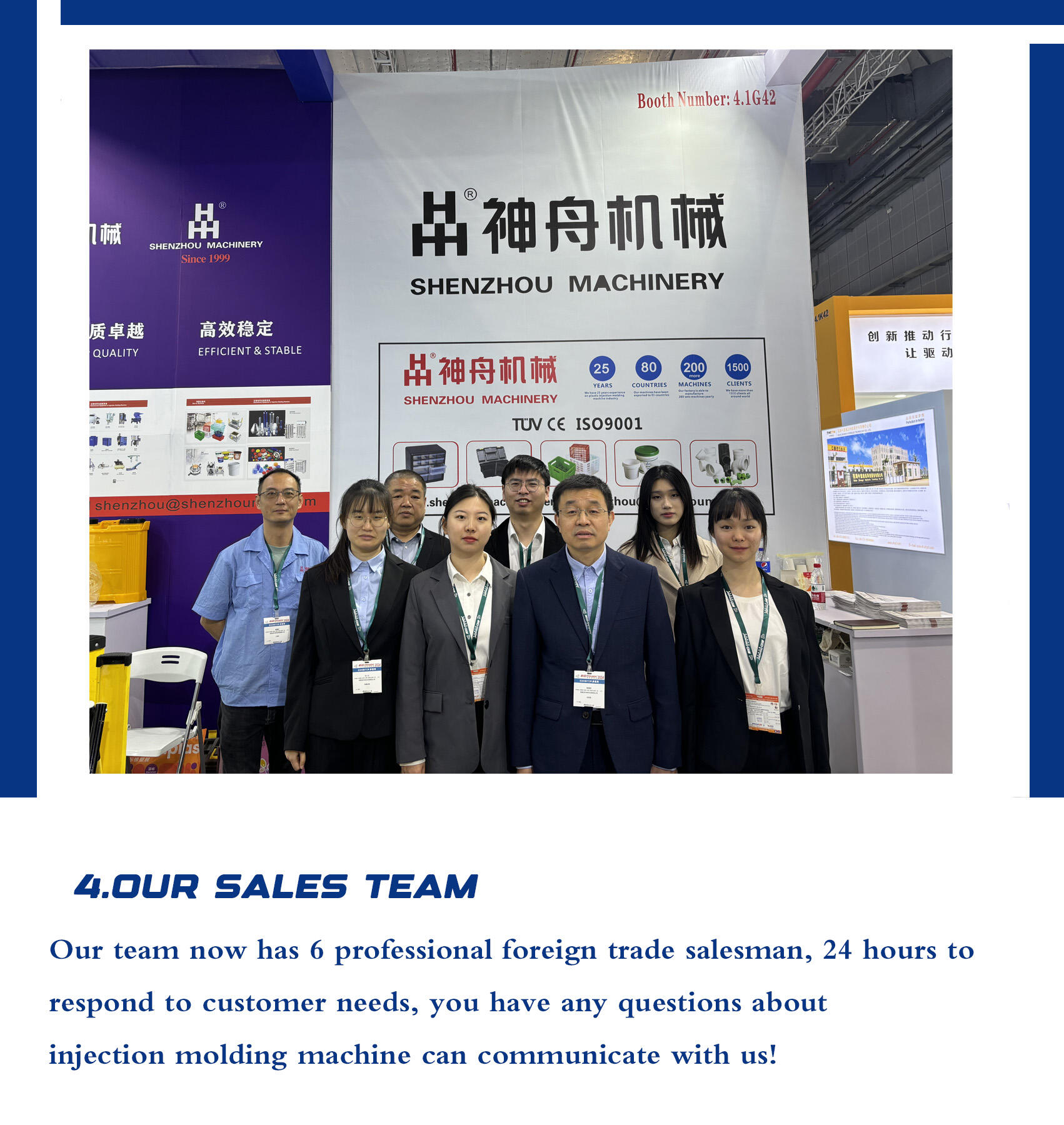

Furthermore, the SHENZHOU’s Injection Molding Machine is backed by excellent customer service and technical support. Our team of experts is always ready to assist you with any questions or concerns you may have, ensuring that your production process runs smoothly and efficiently.

The SHENZHOU’s Plastic Factory Direct Sale Centrifuge Tube Tube Bottom Centrifugal Pipe Injection Molding Machine is a top-of-the-line solution for all your plastic manufacturing needs. With its advanced technology, user-friendly design, and durable construction, this machine will help you streamline your production process and achieve superior results. Don't settle for anything less - choose SHENZHOU for your injection molding needs

项目 ITEM |

单位UNIT |

SZ—2400A |

|||||||

注射装置 INJECTION UNIT |

|||||||||

螺杆直径 |

SCREW DIAMETER |

mm |

55 |

60 |

65 |

||||

螺杆长径比 |

SCREW LID RATIO |

L/D |

22.9 |

21 |

19.4 |

||||

理论注射容积 |

THEORETICAL SHOT VOLUME |

CM3 |

665 |

791 |

929 |

||||

注射质量 - PS料 |

SHOT WEIGHT - PS |

g |

605 |

720 |

845 |

||||

注射压力 |

INJECTION PRESSURE |

Mpa |

210 |

176 |

150 |

||||

理论注射速率 - PS料 |

THEORETICAL INJECTION RATE - PS |

g/s |

176.5 |

210 |

245 |

||||

塑化能力 - PS料 |

PLASTICISING CAPACITY |

g/s |

26.4 |

32.5 |

40 |

||||

螺杆驱动扭矩 |

SCREW TORQUE |

N/m |

2000 |

||||||

螺杆最高转速 |

MAX. SCREW ROTATE SPEED |

r/min |

150 |

||||||

洼射行程 |

INJECTION STROKE |

mm |

280 |

||||||

合模装置 CLAMPING UNIT |

|||||||||

合模力 |

MAX. CLAMPING FORCE K |

KN |

2400 |

||||||

移模行程 |

MAX. OPENING STROKE |

mm |

530 |

||||||

拉杆有效间距 - VxH |

SPACE BETWEEN TIE BARS |

mm |

555×555 |

||||||

允许模厚 - MIN-MAX |

MOULD HEIGHT |

mm |

200-570 |

||||||

模板最大开距 |

MAX. DAYLIGHT |

mm |

1100 |

||||||

液压顶出力 |

EJECTOR FORCE |

KN |

61.5 |

||||||

液压顶出行程 |

EJECTOR STROKE |

mm |

135 |

||||||

液压顶出杆总数 |

EJECTOR QUANTITY |

9 |

|||||||

其它 OTHER |

|||||||||

油泵电动机功率 |

PUMP MOTOR POWER |

KW |

22 |

||||||

油泵最高压力 |

PUMP PRESSURE |

Mpa |

16 |

||||||

料简加热功率 |

HEATING POWER |

KW |

18.5 |

||||||

加热区段 |

HEATING ZONE |

5 |

|||||||

机器外形 - LxWxH |

SIZE |

m |

6.2×1.6×2.1 |

||||||

机器净重 |

NET WEIGHT |

t |

8.0 |

||||||

油箱容积 |

OIL TANK CAPACITY |

L |

440 |

||||||

国际公认型号 |

INTERNATIONAL DESIGNATION |

2400—1390 |

|||||||

A:"Quality is priority. we always attach great importance to quality controlling from the very beginning to the very end and we have a dedicated quality control department.

3. Q:What are your normal lead times

A:Our company typical lead times range from 25-35days after receipt of order. We also have independent venues and engineers to deal with more urgent orders, which can be shipped within 2 weeks.

A: Our factory is located in Shenzhou Machinery, No. 22 Zhenbei Road, Fenghuang Town, Zhangjiagang City China. All our clients, from home or abroad, are warmly welcome to visit us