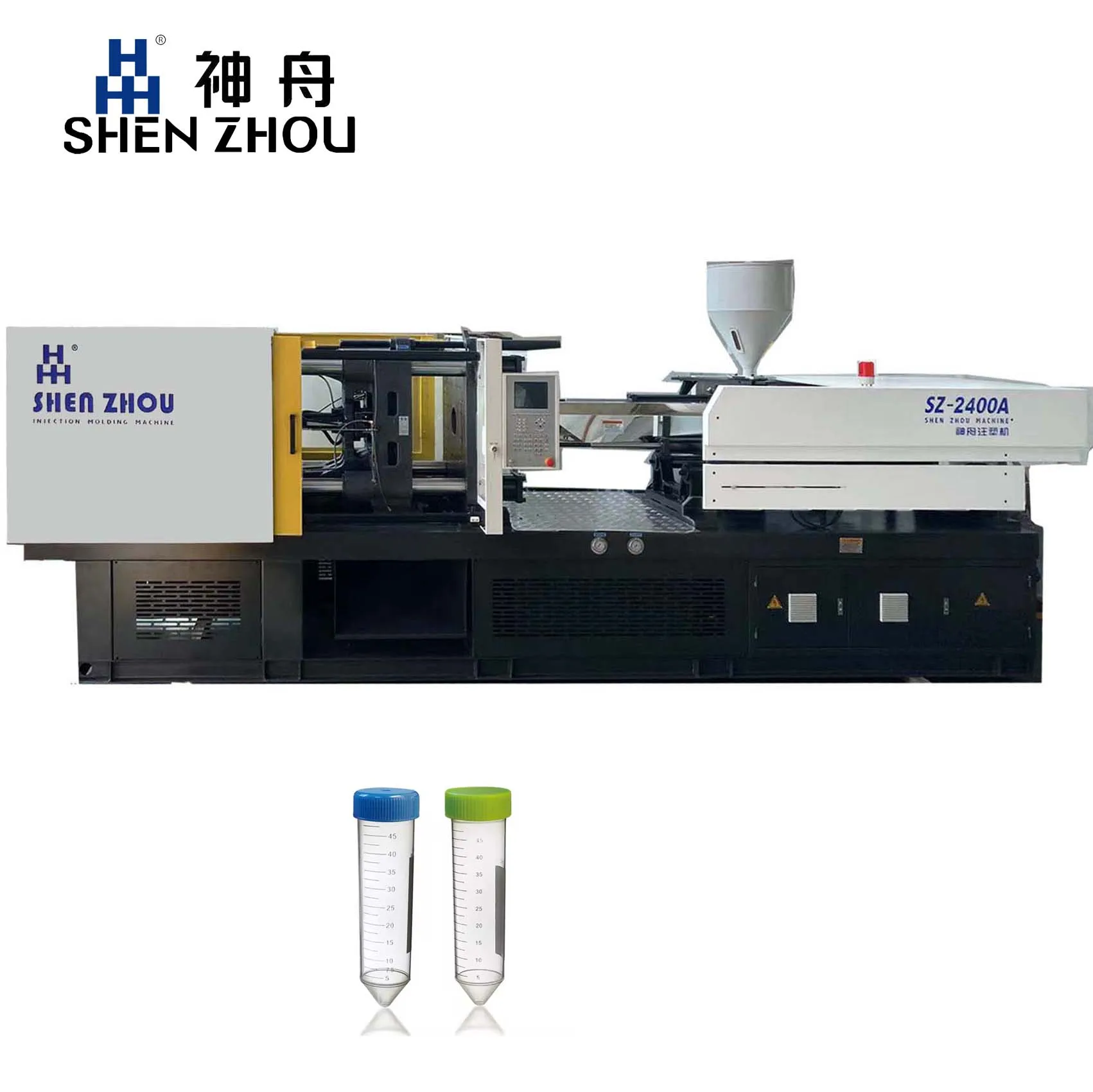

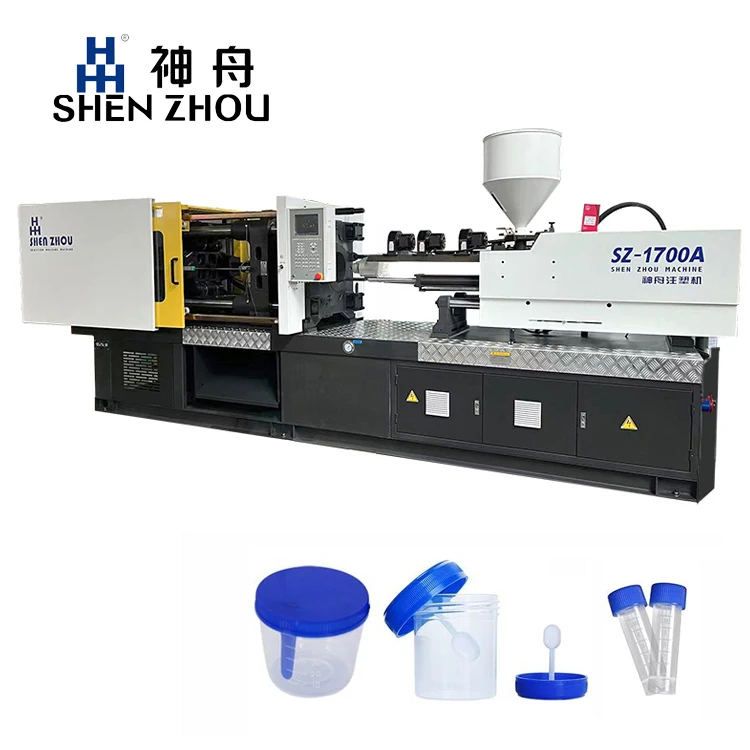

Plastic Manual Eva Injection Molding Machine Price With CE and ISO

SZ—4800A Injection molding machine.

SCREW DIAMETER (mm) : 75

SCREW LID RATIO (L/D) :21

THEORETICAL SHOT VOLUME (CM3): 1545

SHOT WEIGHT(PS) (g):1406

Description

Introducing, the SHENZHOU’s Plastic Manual Eva Injection Molding Machine, the perfect solution for all your injection molding needs. With its durable construction and high-quality materials, this machine is designed to deliver consistent and reliable results every time.

This injection molding machine is incredibly versatile, making it suitable for a wide range of applications. Whether you are producing small components or larger parts, the SHENZHOU’s Plastic Manual Eva Injection Molding Machine can handle it all with ease. Its manual operation allows for precise control over the molding process, ensuring that you get the exact results you desire.

One of the standout features of this machine is its ability to work with Eva materials. Eva is a popular thermoplastic material known for its flexibility, durability, and resistance to impact. With the SHENZHOU’s Plastic Manual Eva Injection Molding Machine, you can effortlessly mold Eva materials into the desired shapes and sizes, achieving professional results every time.

In addition to its exceptional performance, this injection molding machine is also incredibly user-friendly. It is easy to operate, even for those who are new to injection molding. The machine comes with clear instructions and a user-friendly interface, making it simple to set up and start producing high-quality parts in no time.

When it comes to safety and reliability, the SHENZHOU’s Plastic Manual Eva Injection Molding Machine excels. It is CE and ISO certified, ensuring that it meets the highest standards of quality and safety. You can trust that this machine is built to last and will provide years of efficient and reliable service.

The SHENZHOU’s Plastic Manual Eva Injection Molding Machine is a top-quality product that offers exceptional performance, versatility, and ease of use. With its affordable price and superior construction, this machine is a must-have for any business or individual looking to produce high-quality molded parts. Invest in the SHENZHOU’s Plastic Manual Eva Injection Molding Machine today and take your injection molding projects to the next level

项目 ITEM |

单位UNIT |

SZ—3000A |

|||||||

注射装置 INJECTION UNIT |

|||||||||

螺杆直径 |

SCREW DIAMETER |

mm |

60 |

65 |

70 |

||||

螺杆长径比 |

SCREW LID RATIO |

L/D |

22.7 |

21 |

19.5 |

||||

理论注射容积 |

THEORETICAL SHOT VOLUME |

CM3 |

848 |

995 |

1154 |

||||

注射质量 - PS料 |

SHOT WEIGHT - PS |

g |

772 |

905 |

1050 |

||||

注射压力 |

INJECTION PRESSURE |

Mpa |

207 |

176 |

152 |

||||

理论注射速率 - PS料 |

THEORETICAL INJECTION RATE - PS |

g/s |

241 |

283 |

328 |

||||

塑化能力 - PS料 |

PLASTICISING CAPACITY |

g/s |

35.2 |

43.3 |

51.8 |

||||

螺杆驱动扭矩 |

SCREW TORQUE |

N/m |

2530 |

||||||

螺杆最高转速 |

MAX. SCREW ROTATE SPEED |

r/min |

150 |

||||||

洼射行程 |

INJECTION STROKE |

mm |

300 |

||||||

合模装置 CLAMPING UNIT |

|||||||||

合模力 |

MAX. CLAMPING FORCE K |

KN |

3000 |

||||||

移模行程 |

MAX. OPENING STROKE |

mm |

590 |

||||||

拉杆有效间距 - VxH |

SPACE BETWEEN TIE BARS |

mm |

610×610 |

||||||

允许模厚 - MIN-MAX |

MOULD HEIGHT |

mm |

220-630 |

||||||

模板最大开距 |

MAX. DAYLIGHT |

mm |

1220 |

||||||

液压顶出力 |

EJECTOR FORCE |

KN |

70.6 |

||||||

液压顶出行程 |

EJECTOR STROKE |

mm |

150 |

||||||

液压顶出杆总数 |

EJECTOR QUANTITY |

9 |

|||||||

其它 OTHER |

|||||||||

油泵电动机功率 |

PUMP MOTOR POWER |

KW |

30 |

||||||

油泵最高压力 |

PUMP PRESSURE |

Mpa |

16 |

||||||

料简加热功率 |

HEATING POWER |

KW |

22 |

||||||

加热区段 |

HEATING ZONE |

5 |

|||||||

机器外形 - LxWxH |

SIZE |

m |

6.7×1.75×2.25 |

||||||

机器净重 |

NET WEIGHT |

t |

11 |

||||||

油箱容积 |

OIL TANK CAPACITY |

L |

560 |

||||||

国际公认型号 |

INTERNATIONAL DESIGNATION |

3000—1750 |

|||||||

The warranty period of the machine is 1 year, and the after-sale is lifelong

LC 、TT、credit card

Of course, we can send professional engineers to the customer's location for professional technical guidance and training

Yes, we will work out a suitable plan according to the client's budget

We have agents in Peru, Zimbabwe, Ethiopia, Kazakhstan, India

At least 20 years