Introducing, the SHENZHOU’s Plastic Pet Bottles Caps Preform Making Injector Injection Molding Machine!

This top-of-the-line machine is perfect for creating high-quality plastic bottles, caps, and preforms with ease. Whether you are a small business owner or a large-scale manufacturer, this machine is versatile enough to meet all your production needs.

The SHENZHOU machine is designed for efficiency and precision. It can produce a wide range of bottle sizes and shapes, making it ideal for any packaging requirements. With its advanced injection molding technology, you can trust that each product will be uniform in quality and appearance.

One of the key features of this machine is its user-friendly interface. With intuitive controls and settings, you can easily adjust the machine to meet your specific production requirements. Whether you need to change the mold, adjust the injection pressure, or set the cooling time, the SHENZHOU machine makes it simple and hassle-free.

Not only is this machine easy to use, but it is also built to last. Made from durable materials and components, the SHENZHOU machine is designed for longevity and reliability. You can trust that it will provide consistent performance for years to come, ensuring that your production process runs smoothly and efficiently.

In addition to its exceptional performance, the SHENZHOU machine is also energy-efficient. With its innovative design and technology, it consumes minimal energy while still delivering top-notch results. This not only helps reduce your operational costs but also contributes to a more sustainable and eco-friendly production process.

The SHENZHOU’s Plastic Pet Bottles Caps Preform Making Injector Injection Molding Machine is a must-have for any manufacturer looking to streamline their production process and enhance the quality of their plastic products. With its superior performance, durability, and energy efficiency, this machine is sure to exceed your expectations and deliver outstanding results. Upgrade to the SHENZHOU machine today and take your production capabilities to the next level

项目 ITEM |

|

单位UNIT |

SZ—4800A |

|

|

|

注射装置 INJECTION UNIT |

|

|

|

|

|

|

螺杆直径 |

SCREW DIAMETER |

mm |

70 |

75 |

80 |

|

|

|

|

螺杆长径比 |

SCREW LID RATIO |

L/D |

22.6 |

21 |

19.7 |

|

|

|

|

理论注射容积 |

THEORETICAL SHOT VOLUME |

CM3 |

1346 |

1545 |

1758 |

|

|

|

|

注射质量 - PS料 |

SHOT WEIGHT - PS |

g |

1225 |

1406 |

1600 |

|

|

|

|

注射压力 |

INJECTION PRESSURE |

Mpa |

201 |

175 |

154 |

|

|

|

|

理论注射速率 - PS料 |

THEORETICAL INJECTION RATE - PS |

g/s |

370 |

423 |

484 |

|

|

|

|

塑化能力 - PS料 |

PLASTICISING CAPACITY |

g/s |

60.4 |

71.4 |

83.7 |

|

|

|

|

螺杆驱动扭矩 |

SCREW TORQUE |

N/m |

3490 |

|

|

|

|

螺杆最高转速 |

MAX. SCREW ROTATE SPEED |

r/min |

150 |

|

|

|

|

洼射行程 |

INJECTION STROKE |

mm |

350 |

|

|

|

|

合模装置 CLAMPING UNIT |

|

|

|

|

|

合模力 |

MAX. CLAMPING FORCE K |

KN |

4800 |

|

|

|

|

移模行程 |

MAX. OPENING STROKE |

mm |

770 |

|

|

|

|

拉杆有效间距 - VxH |

SPACE BETWEEN TIE BARS |

mm |

760×760 |

|

|

|

|

允许模厚 - MIN-MAX |

MOULD HEIGHT |

mm |

280-790 |

|

|

|

|

模板最大开距 |

MAX. DAYLIGHT |

mm |

1560 |

|

|

|

|

液压顶出力 |

EJECTOR FORCE |

KN |

113.4 |

|

|

|

|

液压顶出行程 |

EJECTOR STROKE |

mm |

195 |

|

|

|

|

液压顶出杆总数 |

EJECTOR QUANTITY |

|

13 |

|

|

|

|

其它 OTHER |

|

|

|

|

|

油泵电动机功率 |

PUMP MOTOR POWER |

KW |

45 |

|

|

|

|

油泵最高压力 |

PUMP PRESSURE |

Mpa |

16 |

|

|

|

|

料简加热功率 |

HEATING POWER |

KW |

28 |

|

|

|

|

加热区段 |

HEATING ZONE |

|

5 |

|

|

|

|

机器外形 - LxWxH |

SIZE |

m |

7.5×2.1×2.45 |

|

|

|

|

机器净重 |

NET WEIGHT |

t |

20 |

|

|

|

|

油箱容积 |

OIL TANK CAPACITY |

L |

850 |

|

|

|

|

国际公认型号 |

INTERNATIONAL DESIGNATION |

|

4800—2710 |

|

|

|

|

●New type 5-point toggle device of stable movement curve, gentle shock●Superior mould platen to ensure no out of shape if high-pressure clamping

●Hard chrome plated high tensile strength tie bars made of superior alloy

●Wear-resistant guide for moving platen

●Transducer control clamping stroke

●Many step control for speed and pressure of clamping and opening

●Eiection device offer dwell, single, more, vibration function

●Low pressure mould protection function

●Hydraulic mould height adjustment with rough and fine operation

●Mechanical and electrical dual safety interlock

●Automatic centralized lubrication system with far pressure detector

●Proportional pressure and flow control with fine adjustment and precision

●Know-how manifold design, compact, reasonable and fast respond

●Imported world famous hydraulic valves

●Imported world famous hydraulic sealing rings

●Imported technology hydraulic hose and fittings

●Low noise hydraulic system

●Precision oil filter and oil cooler

●Nitrided screw and barrel with long service life

●Smelted screw with big L/D ratio with good plasticizing and color-fixing

●Double injection cylinder of compact construction and good equilibrant

●Transducer control injection stroke

●The speed of low speed and large torque hydraulic motor can be adjusted

●Screw back pressure control and nozzle anti-leakage control movable hopper for easy remove material

●Injection-catriage can be used for slacking, re-feedingor fixed-feeding

●Speed and pressure of injecting and holding controlled by time or position

●Equipped with reverse device to be easily removed and cleaned

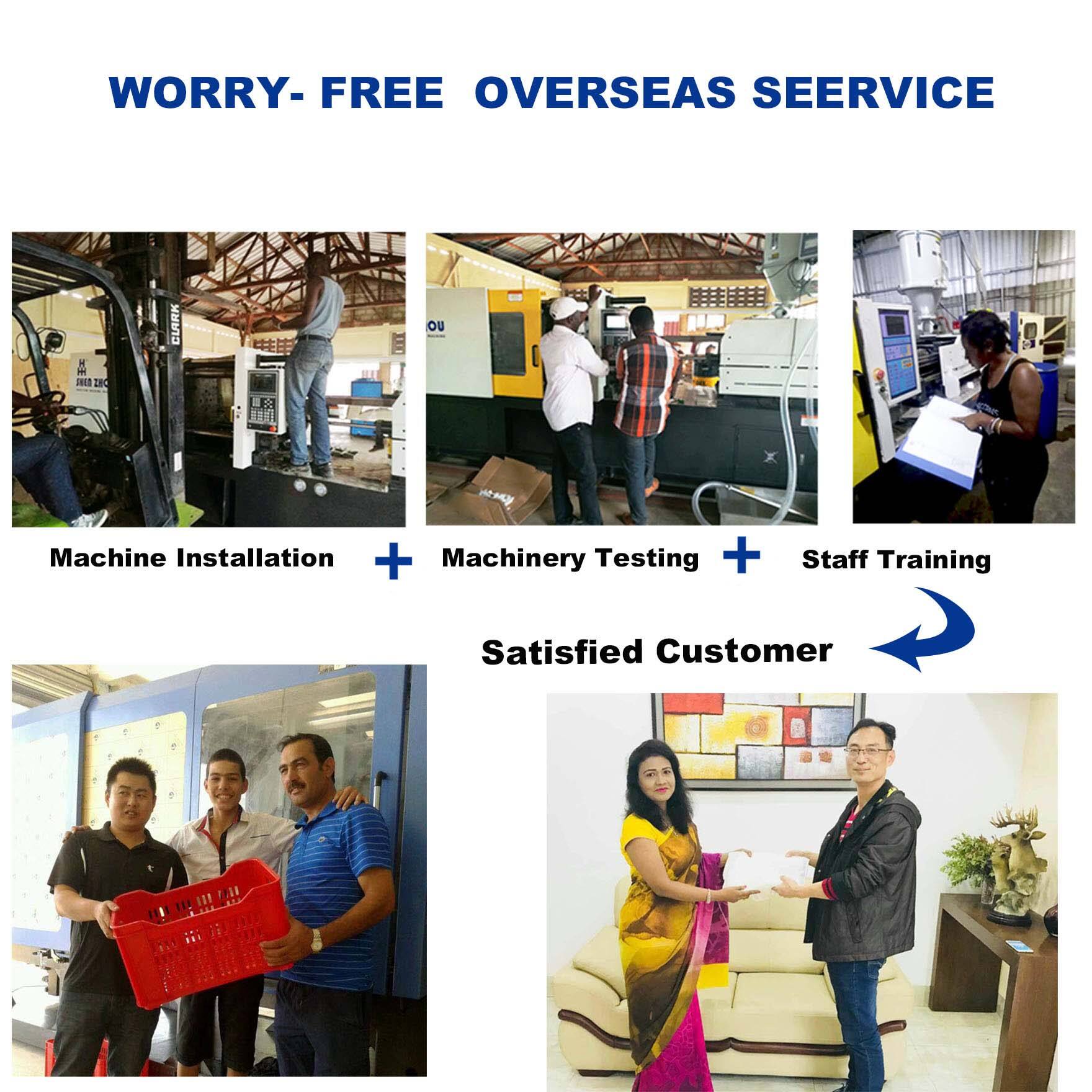

1. 20 years of professional injection molding machine and mold manufacturer, excellent quality, honest management

2. Continuous technological innovation, optimized product structure, longer service life

3. Lifetime maintenance of the product, 24 hours after-sales service

4. The main components are all world-renowned brands

5. Dedicated quality control department

6. Ex-factory price

SHENZHOU-Your trusted plastic processing partner

Our company - injection molding machine, blow molding machine, main blower, mold, computer embroidery machine professional manufacturer - located in the national new port city of Zhangjiagang City, Xizhang Town, close to the Yanjiang Expressway and 204 National Road, close to Shanghai, Nanjing, Suzhou, Wuxi Large and medium-sized cities such as Nantong have convenient transportation

The company has accumulated rich experience in manufacturing injection molding machines for many years, high standard design and precision processing, using imported famous brand hydraulic, electrical and sealing components, and fully creating SZ series automatic computer injection molding machine and peripheral supporting equipment, with its excellent quality and stability. The performance, superior price performance ratio, to the greatest extent to meet the interests and needs of customers

We will apply lubricating oil and spray anti-rust agent to the products before shipment, prepare enough spare parts, and confirm that they are fully fixed before shipment. We pay attention to details and hope to bring you a better experience

1. Q:Are you a factory or trading company

A: Industry and Trade Integration, we supply the factory price with good quality, welcome to visit

2. Q:How does your factory do regarding quality control

A:"Quality is priority. We always attach great importance to quality controlling from the very beginning to the very end and we have a dedicated quality control department

3. Q:What are your normal lead times

A:Our company typical lead times range from 25-35days after receipt of order. We also have independent venues and engineers to deal with more urgent orders, which can be shipped within 2 weeks

4. Q:About the price

A:We will estimate the cost and provide you with the best price. We can guarantee you the best product quality and after-sales service at the same price. Old customers will enjoy more price concessions

5. Q:How is your machine different from other businesses

A:We have optimized the overall layout of each part of the machine to make the machine run smoothly and have a longer service life. The fine parts have exclusive marks, which makes it more convenient for customers to replace parts and use

6. Q:Where is your factory located? How can I visit thereA: Our factory is located in Shenzhou Machinery, No. 22 Zhenbei Road, Fenghuang Town, Zhangjiagang City China. All our clients, from home or abroad, are warmly welcome to visit us

You are welcome to send us samples, we will customize high-quality machines for you! Best wishes for you