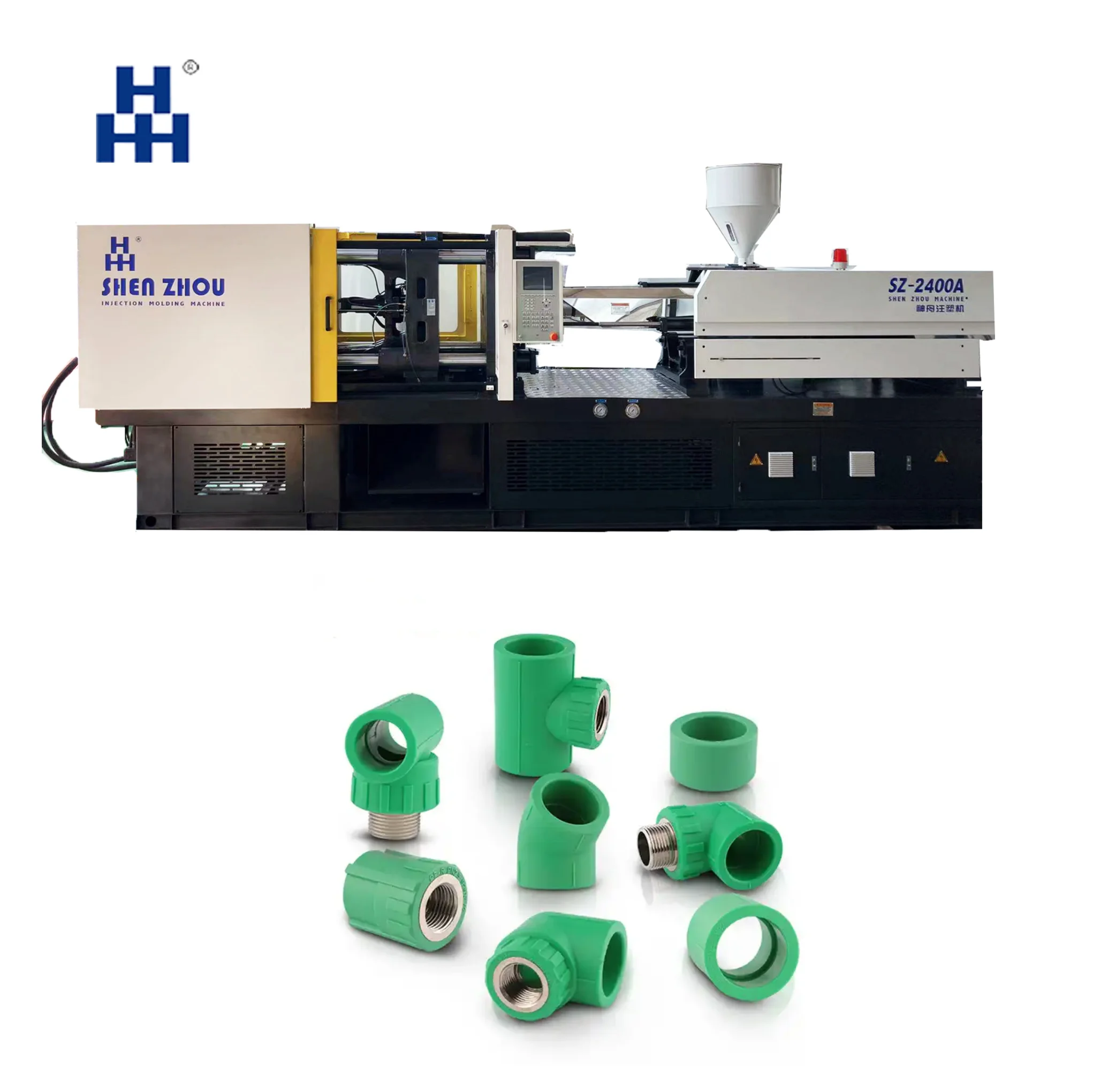

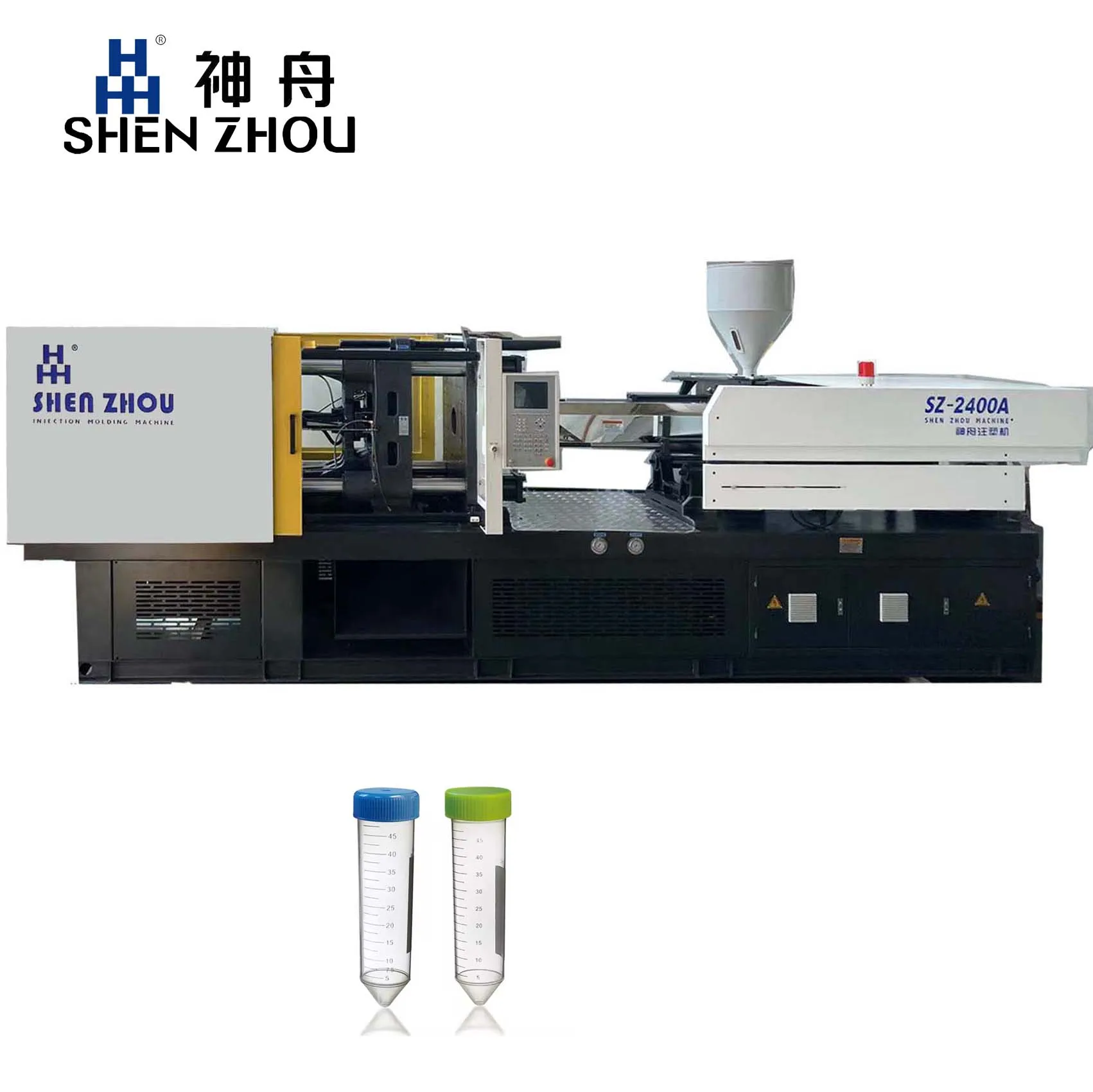

Plastic PPR Heat and Pvc for Pipe Fitting Making Injection Molding Machine

|

ITEM |

UNIT |

SZ—2400A |

||

|

INJECTION UNIT |

|

|

||

|

SCREW DIAMETER |

mm |

55 |

60 |

65 |

|

SCREW LID RATIO |

L/D |

22.9 |

21 |

19.4 |

|

THEORETICAL SHOT VOLUME |

CM3 |

665 |

791 |

929 |

|

SHOT WEIGHT(PS) |

g |

605 |

720 |

845 |

|

INJECTION PRESSURE |

Mpa |

210 |

176 |

150 |

|

THEORETICAL INJECTION RATE(PS) |

g/s |

176.5 |

210 |

245 |

|

PLASTICISING CAPACITY |

g/s |

26.4 |

32.5 |

40 |

|

SCREW TORQUE |

N.m |

2000 |

||

|

MAX.SCREW ROTATE SPEED |

r/min |

150 |

||

|

INJECTION STROKE |

mm |

280 |

||

|

CLAMPING UNIT |

|

|||

|

MAX.CLAMPING FORCE K |

KN |

2400 |

||

|

MAX.OPENING STROKE |

mm |

530 |

||

|

SPACE BETWEEN TIE BARS |

mm |

555×555 |

||

|

MOULD HEIGHT |

mm |

200-570 |

||

|

MAX.DAYLIGHT |

mm |

1100 |

||

|

EJECTOR FORCE |

KN |

61.5 |

||

|

EJECTOR STROKE |

mm |

135 |

||

|

EJECTOR QUANTITY |

|

9 |

||

|

HEATING ZONE |

|

5 |

||

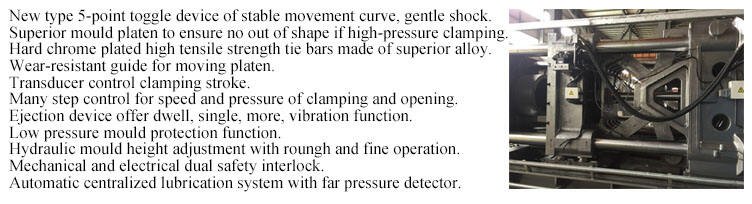

Description

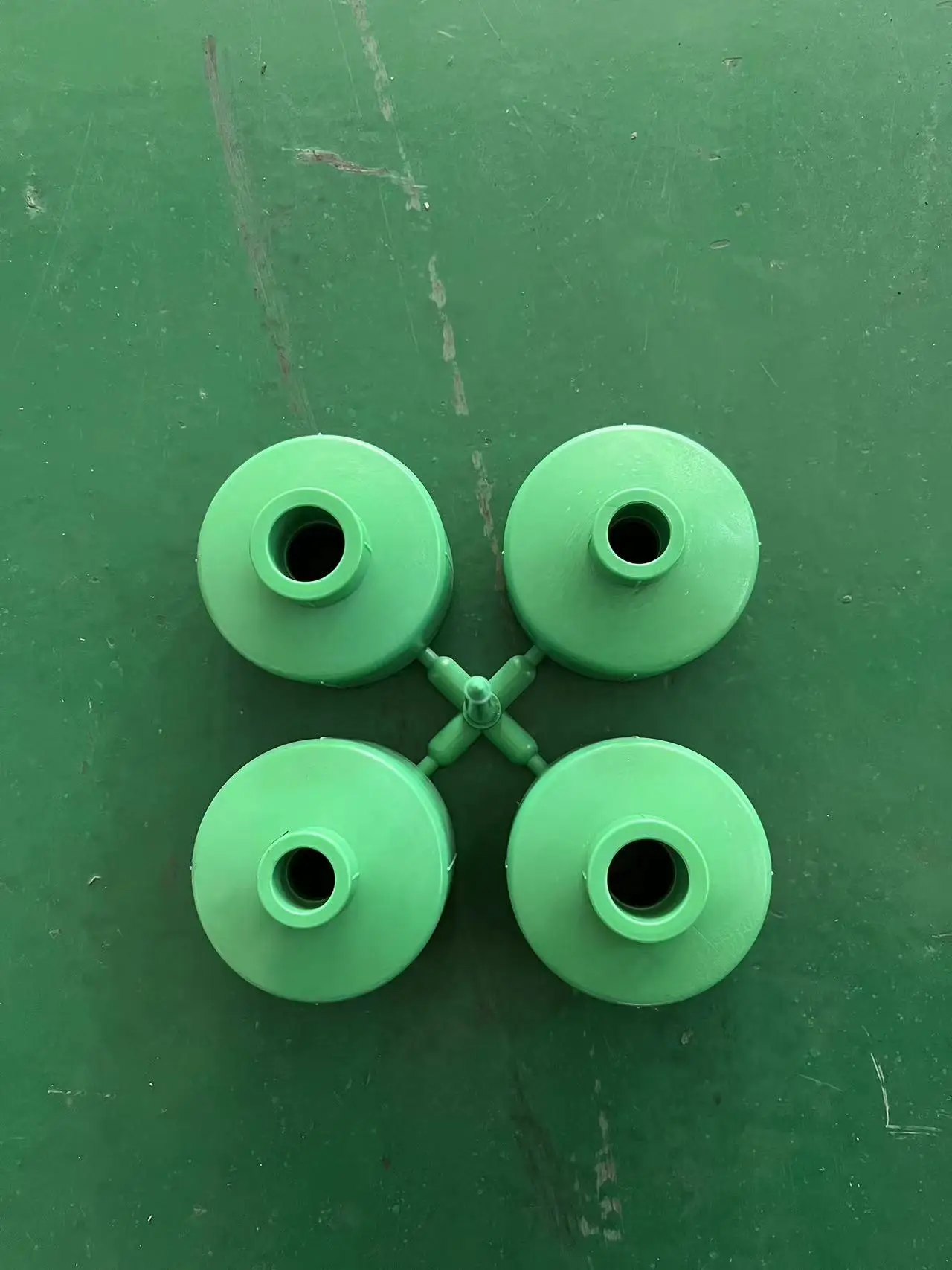

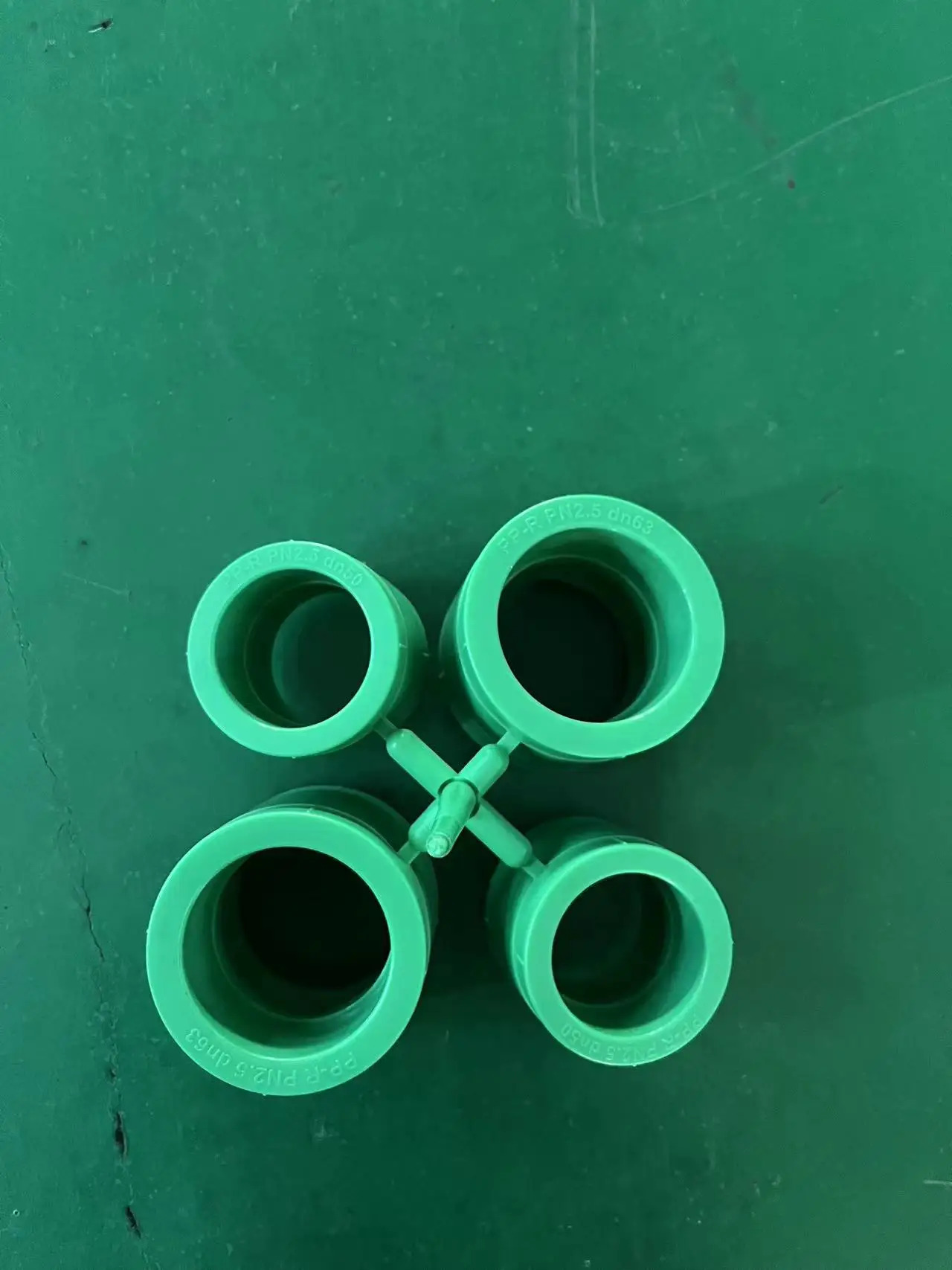

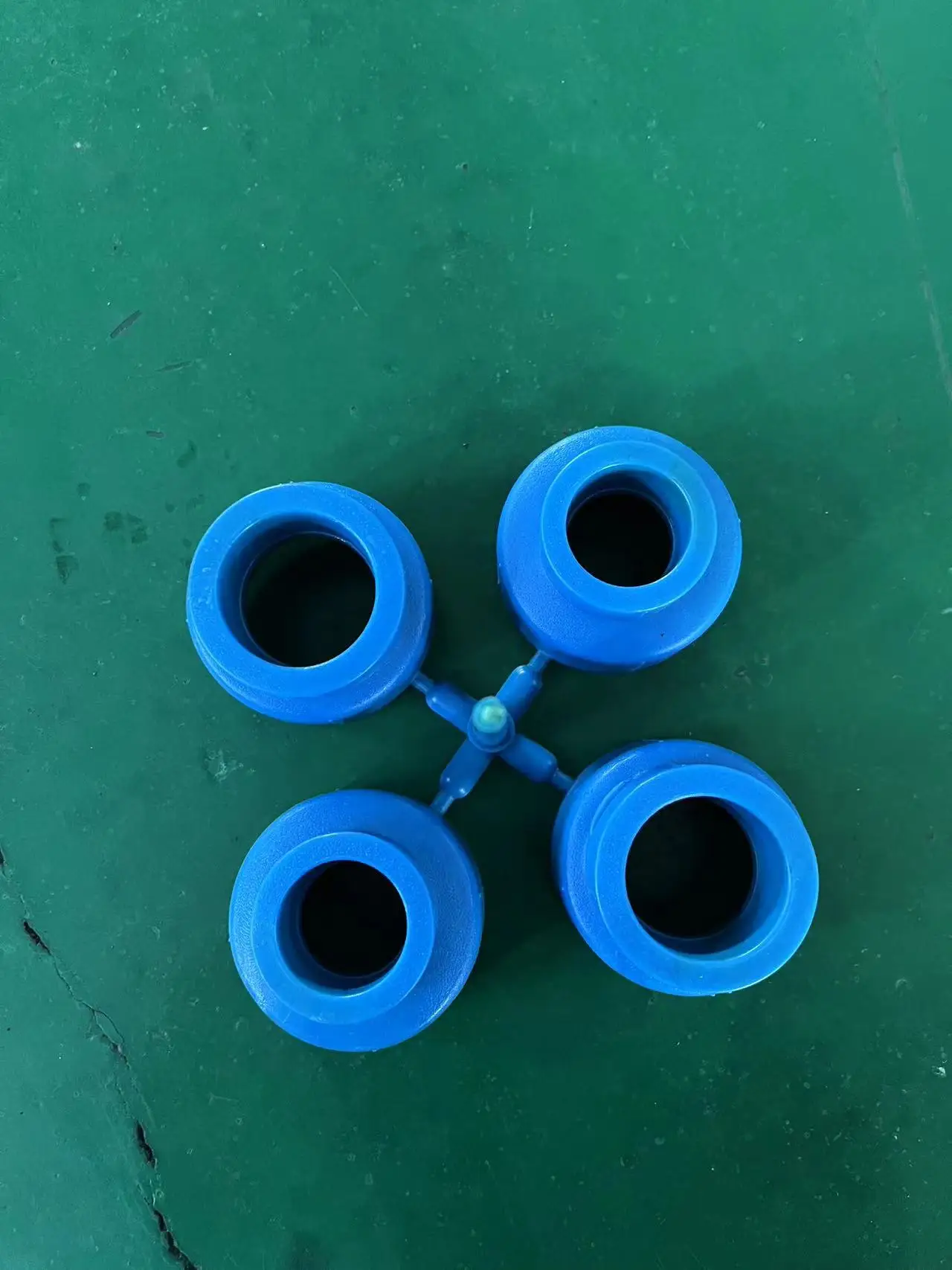

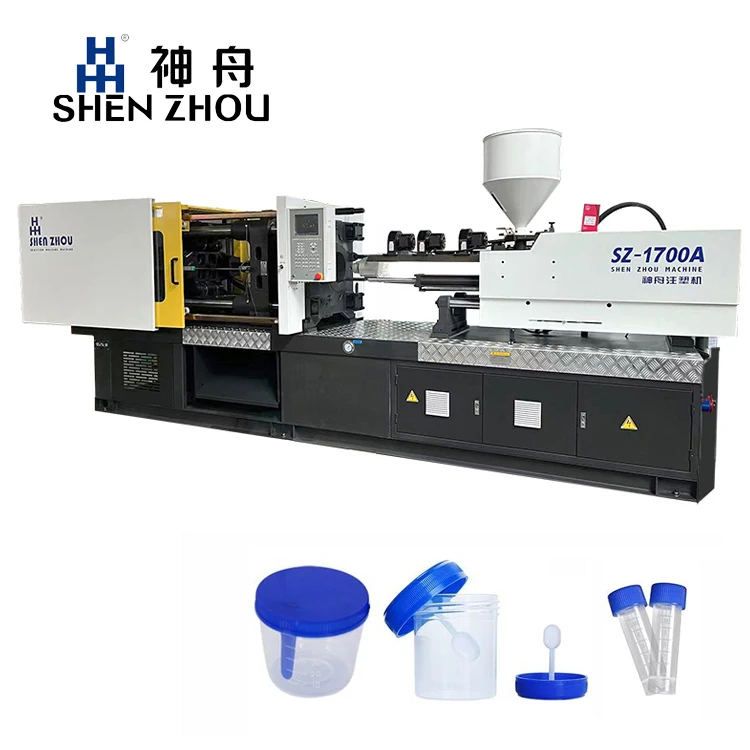

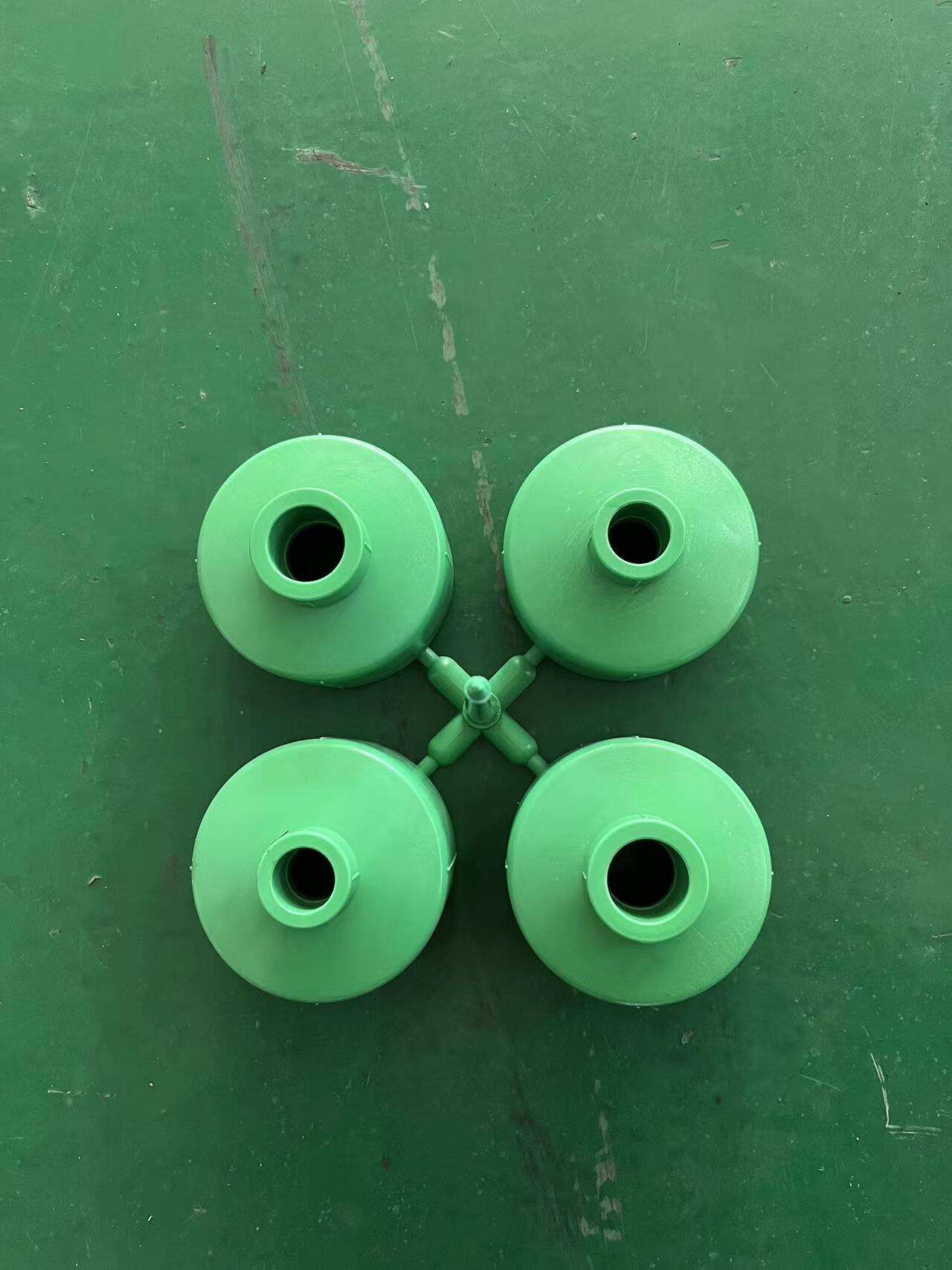

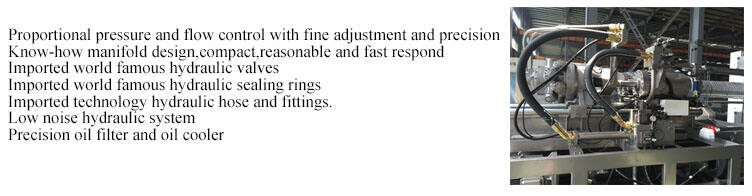

Introducing, the SHENZHOU’s Plastic PPR Heat and PVC Injection Molding Machine - the perfect solution for making pipe fittings with precision and efficiency. This state-of-the-art machine is designed to meet the growing demand for high-quality plastic products in various industries.

The SHENZHOU’s Injection Molding Machine is equipped with advanced technology that allows for seamless production of plastic pipe fittings. Whether you are manufacturing PPR heat or PVC fittings, this machine can handle it all with ease. Its robust construction and reliable performance ensure that you can meet your production targets consistently.

One of the standout features of the SHENZHOU’s Injection Molding Machine is its user-friendly interface. With intuitive controls and a touchscreen display, operators can easily set parameters and monitor the production process. This makes it easier to achieve the desired results without any hassle.

Another key advantage of this machine is its efficiency. The SHENZHOU’s Injection Molding Machine is designed to optimize the production process, reducing cycle times and minimizing wastage. This helps to improve overall productivity and maximize profitability for your business.

In addition, the SHENZHOU’s Injection Molding Machine is built to last. With high-quality components and a durable design, you can rely on this machine to perform consistently over time. This ensures that your investment is protected and that you can continue to meet the demands of your customers.

Whether you are a small-scale manufacturer or a large production facility, the SHENZHOU’s Injection Molding Machine is the ideal choice for making plastic pipe fittings. With its versatility, efficiency, and reliability, this machine offers unmatched value for businesses looking to enhance their production capabilities.

Invest in the SHENZHOU’s Plastic PPR Heat and PVC Injection Molding Machine today and take your pipe fitting production to the next level. Join the many satisfied customers who have experienced the benefits of this innovative machine and see the difference it can make for your business. Order yours now and start creating high-quality plastic pipe fittings with ease

SZ-2400A INJECTION UNIT |

||||||||

ITEM |

UNIT |

VALUE |

||||||

SCREW DIAMETER |

mm |

55 |

60 |

65 |

||||

SCREW L/D RATIO |

L/D |

22.9 |

21 |

19.4 |

||||

Theoretical Shot Volume |

cm^3 |

665 |

791 |

929 |

||||

SHOW WEIGHT - PS |

g |

605 |

720 |

845 |

||||

INJECTION PRESSURE |

Mpa |

210 |

176 |

150 |

||||

THEORETICAL INJECTION RATE - PS |

g/s |

176.5 |

210 |

245 |

||||

PLASTICISING CAPACITY |

g/s |

26.4 |

32.5 |

40 |

||||

SCREW TORQUE |

N/m |

2000 |

||||||

MAX. SCREW ROTATE SPEED |

r/min |

150 |

||||||

INJECTION STROKE |

mm |

280 |

||||||

SZ-2400A CLAMPING UNIT |

||||

ITEM |

UNIT |

VALUE |

||

MAX. CLAMPING FORCE |

KN |

2400 |

||

MAX. OPENING STROKE |

mm |

530 |

||

SPACE BETWEEN TIE BARS |

mm |

555*555 |

||

MOULD HEIGHT |

mm |

200-570 |

||

MAX. DAYLIGHT |

mm |

1100 |

||

EJECTOR FORCE |

KN |

61.5 |

||

EJECTOR STROKE |

mm |

135 |

||

EJECTOR QUANTITY |

9 |

|||

SZ-2400A OTHER |

||||

ITEM |

UNIT |

VALUE |

||

PUMP MOTOR POWER |

KW |

22 |

||

PUMP PRESSURE |

Mpa |

16 |

||

HEATING POWER |

KW |

18.5 |

||

HEATING ZONE |

5 |

|||

SIZE |

m |

6.2*1.6*2.1 |

||

NET WEIGHT |

t |

8.0 |

||

OIL TANK CAPACITY |

L |

440 |

||

INTERNATIONAL DESIGNATION |

2400-1390 |

|||

SHENZHOU-Your trusted plastic processing partner

A: Our factory is located in Shenzhou Machinery, No. 22 Zhenbei Road, Fenghuang Town, Zhangjiagang City China. All our clients, from home or abroad, are warmly welcome to visit us