Description

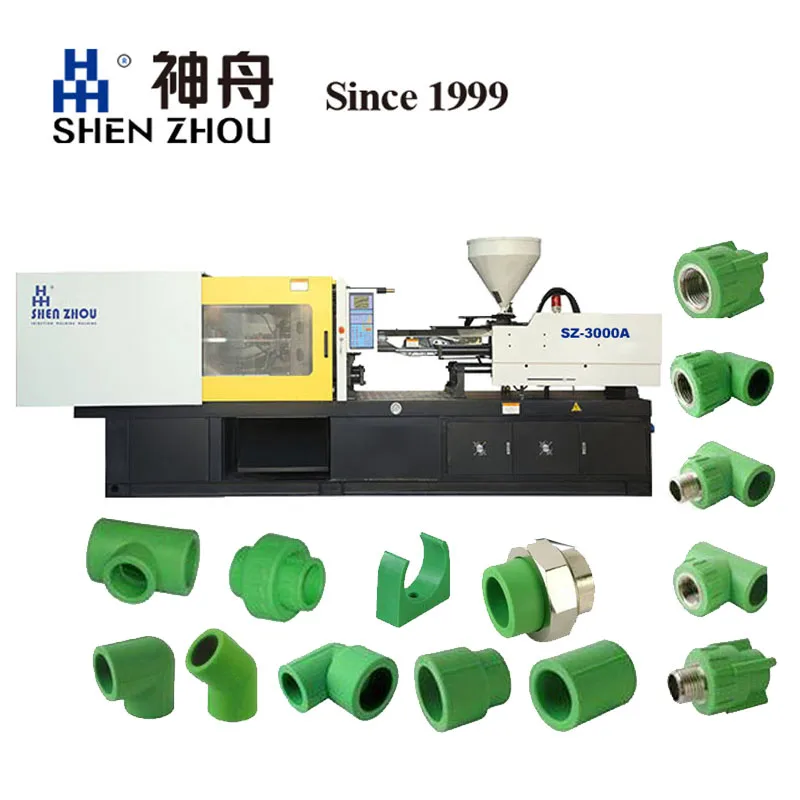

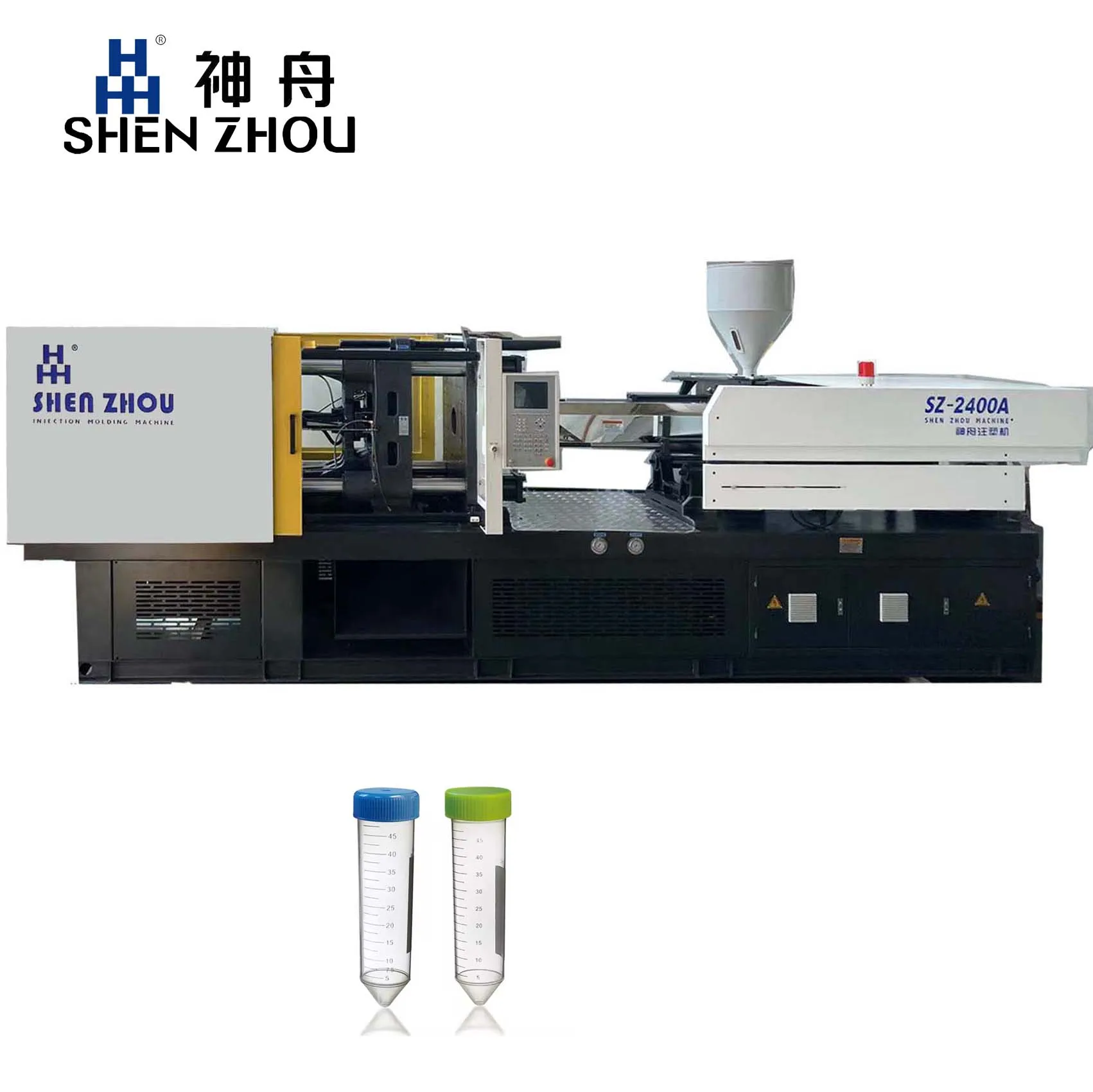

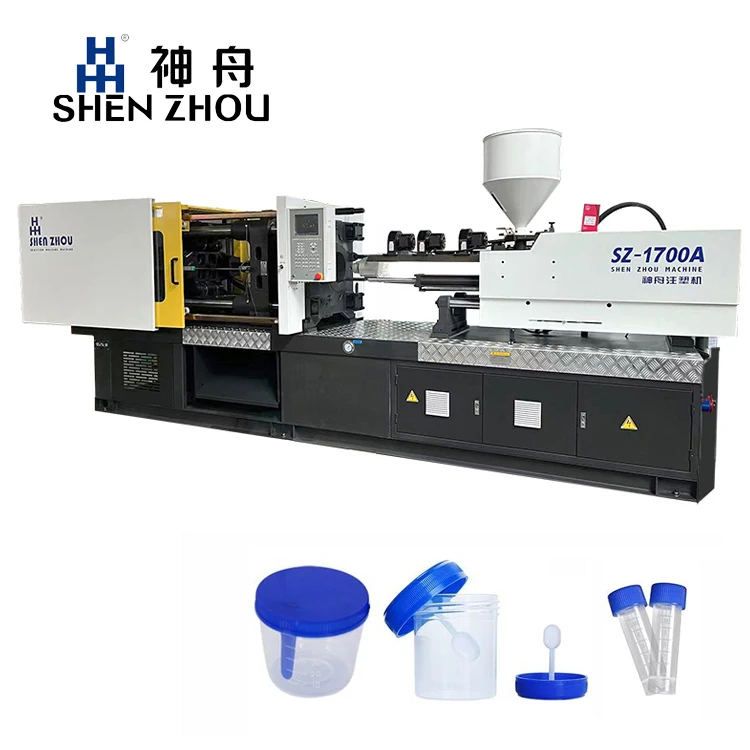

Introducing, the SHENZHOU’s Plastic PPR PVC PP Pipe Fittings Fitting Injection Mold Moulding Molding Machine, the ultimate solution for manufacturing high-quality pipe fittings with precision and efficiency.

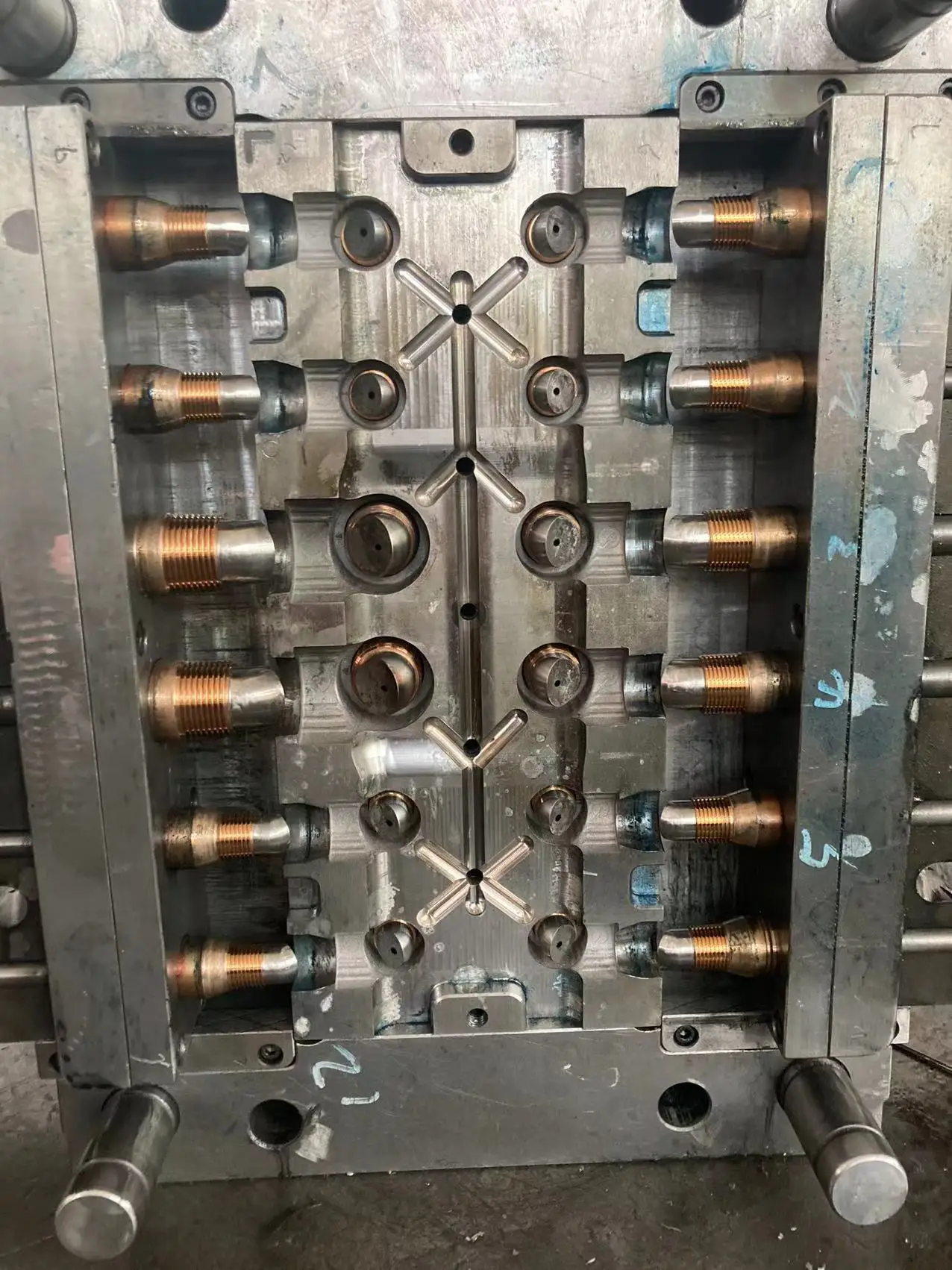

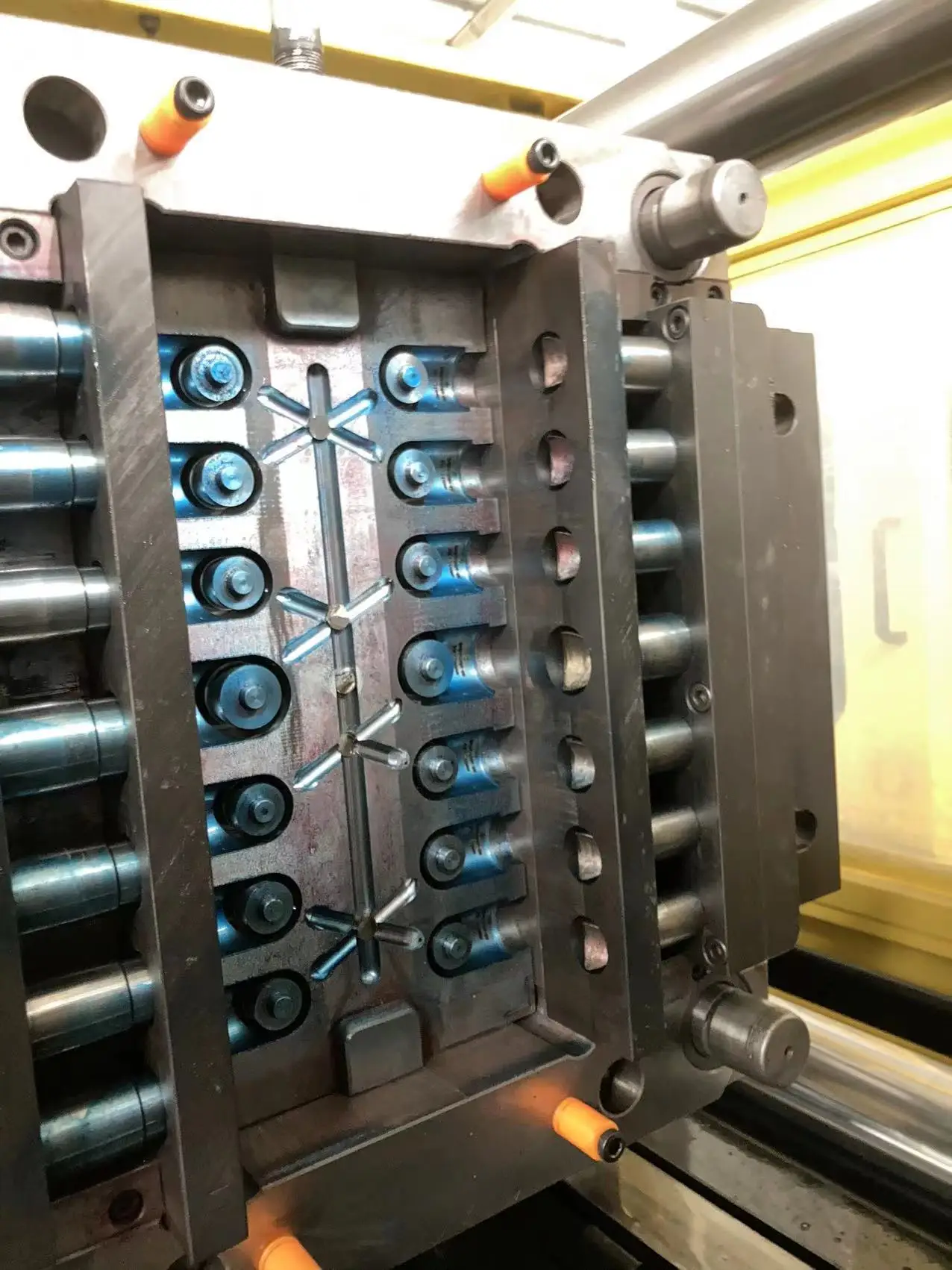

This advanced machine is designed to streamline the injection molding process, allowing for seamless production of various types of plastic pipe fittings including PPR, PVC, and PP. Whether you are looking to create elbows, tees, reducers, or any other type of fitting, this machine has got you covered.

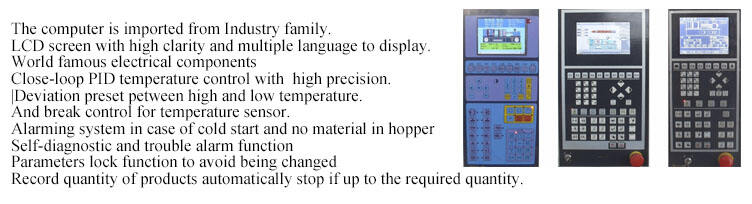

The SHENZHOU machine boasts a user-friendly interface, making it easy for operators to set up and adjust the machine for different molding requirements. With its innovative design and cutting-edge technology, it ensures precise molding of pipe fittings with minimal wastage and maximum efficiency.

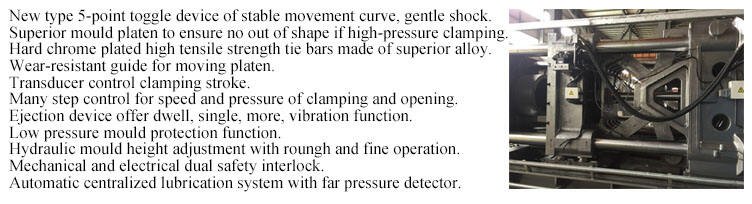

Made from durable materials, the SHENZHOU machine is built to last and can withstand the rigors of continuous operation. Its robust construction and reliable performance make it a valuable asset for any manufacturing facility looking to increase their productivity and output.

In addition, this machine is equipped with safety features to protect operators during operation, ensuring a secure working environment. With its high-speed operation and consistent results, the SHENZHOU machine delivers exceptional quality pipe fittings that meet industry standards and exceed expectations.

Whether you are a small-scale manufacturer or a large industrial operation, the SHENZHOU’s Plastic PPR PVC PP Pipe Fittings Fitting Injection Mold Moulding Molding Machine is the perfect choice for all your molding needs. Experience the difference that this machine can make in your production process and take your business to the next level.

Invest in the SHENZHOU’s Plastic PPR PVC PP Pipe Fittings Fitting Injection Mold Moulding Molding Machine today and enjoy reliable performance, precision molding, and unmatched efficiency. Upgrade your manufacturing capabilities with this top-of-the-line machine and stay ahead of the competition

INJECTION UNIT |

||||||||

ITEM |

UNIT |

VALUE |

||||||

SCREW DIAMETER |

mm |

45 |

50 |

55 |

||||

SCREW L/D RATIO |

L/D |

23.3 |

21 |

19.1 |

||||

Theoretical Shot Volume |

cm^3 |

358 |

442 |

534 |

||||

SHOW WEIGHT - PS |

g |

326 |

402 |

486 |

||||

INJECTION PRESSURE |

Mpa |

219 |

178 |

147 |

||||

THEORETICAL INJECTION RATE - PS |

g/s |

142 |

175 |

212 |

||||

PLASTICISING CAPACITY |

g/s |

20.1 |

26.5 |

34.2 |

||||

SCREW TORQUE |

N/m |

1250 |

||||||

MAX. SCREW ROTATE SPEED |

r/min |

200 |

||||||

INJECTION STROKE |

mm |

225 |

||||||

CLAMPING UNIT |

||||

ITEM |

UNIT |

VALUE |

||

MAX. CLAMPING FORCE |

KN |

1600 |

||

MAX. OPENING STROKE |

mm |

460 |

||

SPACE BETWEEN TIE BARS |

mm |

480*480 |

||

MOULD HEIGHT |

mm |

180~500 |

||

MAX. DAYLIGHT |

mm |

960 |

||

EJECTOR FORCE |

kn |

45.2 |

||

EJECTOR STROKE |

mm |

115 |

||

EJECTOR QUANTITY |

pc |

5 |

||

OTHER |

||||

ITEM |

UNIT |

VALUE |

||

PUMP MOTOR POWER |

KW |

15 |

||

PUMP PRESSURE |

Mpa |

16 |

||

HEATING POWER |

KW |

13.6 |

||

HEATING ZONE |

4 |

|||

SIZE |

m |

5.3*1.35*1.9 |

||

NET WEIGHT |

t |

5.6 |

||

OIL TANK CAPACITY |

L |

420 |

||

INTERNATIONAL DESIGNATION |

1700—785 |

|||

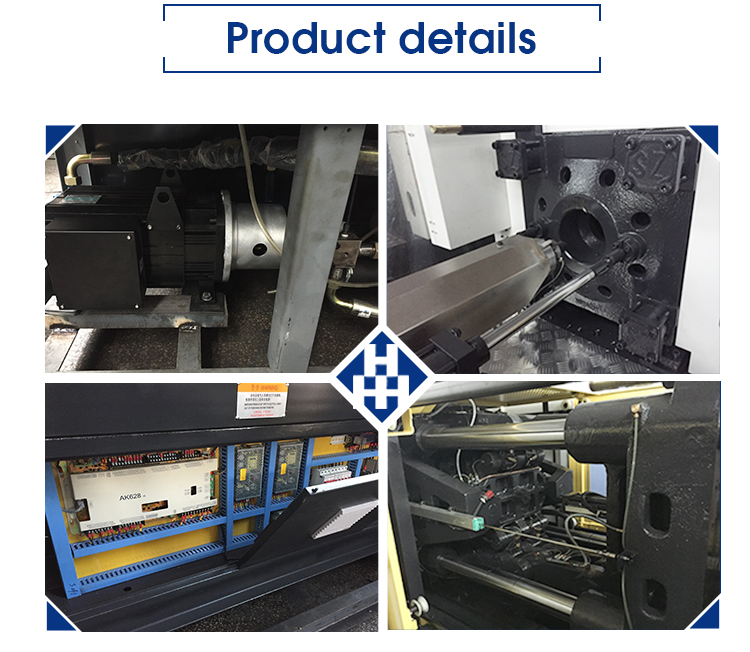

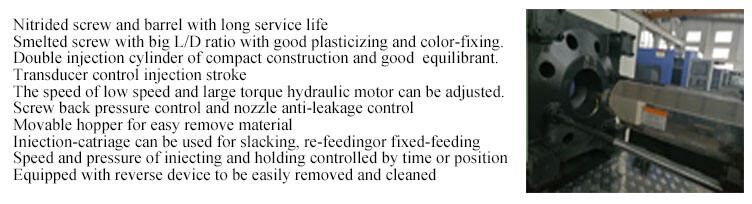

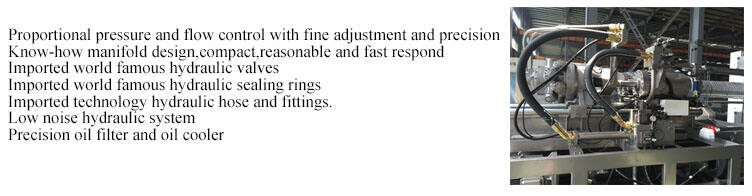

The company has accumulated rich experience in manufacturing injection molding machines for many years, high standard design and precision processing, using imported famous brand hydraulic, electrical and sealing components, and fully creating SZ series automatic computer injection molding machine and peripheral supporting equipment, with its excellent quality and stability. The performance, superior price performance ratio, to the greatest extent to meet the interests and needs of customers

A: Industry and Trade Integration, we supply the factory price with good quality, welcome to visit

2. Q:Where is your factory located? How can I visit there

A: Our factory is located in Shenzhou Machinery, No. 22 Zhenbei Road, Fenghuang Town, Zhangjiagang City China. All our clients, from home or abroad, are warmly welcome to visit us

3. Q:How does your factory do regarding quality control

A:"Quality is priority. we always attach great importance to quality controlling from the very beginning to the very end and we have a dedicated quality control department