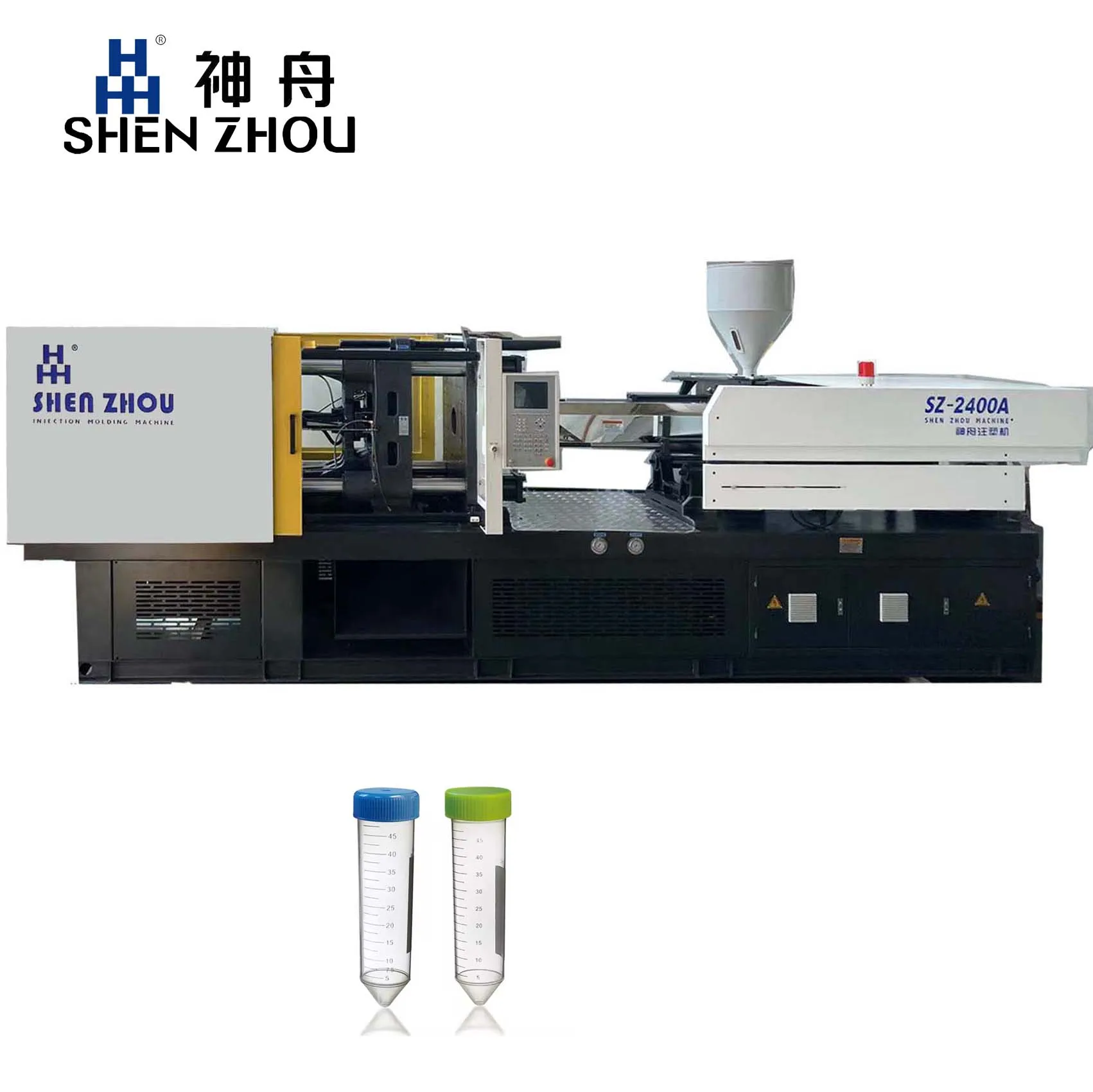

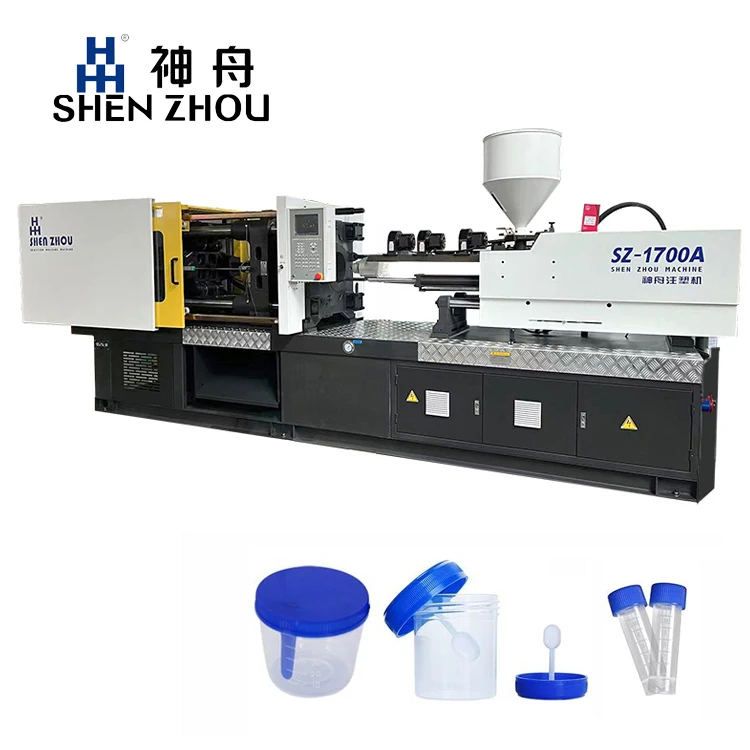

Plastic Restaurant Dining Room Chair Stackable Windmill Stool Injection Making Molding Machine

Description

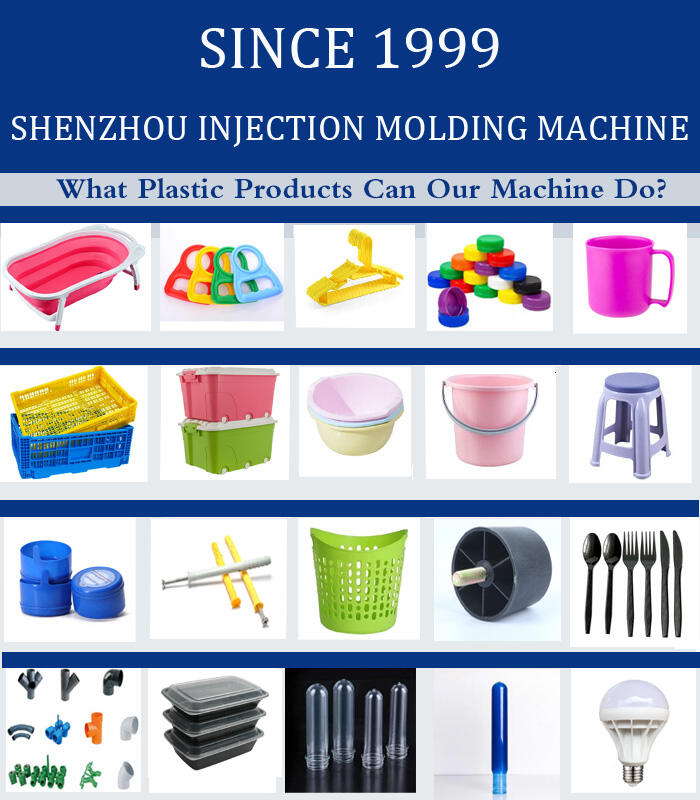

Introducing, the SHENZHOU’s Plastic Restaurant Dining Room Chair Stackable Windmill Stool Injection Making Molding Machine, a game-changer in the world of furniture manufacturing. This innovative machine is designed to revolutionize the production process of plastic chairs and stools, making it easier and more efficient than ever before.

With its cutting-edge technology and top-of-the-line components, the SHENZHOU’s Molding Machine is capable of producing high-quality plastic furniture with precision and speed. Whether you are a furniture manufacturer looking to ramp up production or a restaurant owner in need of sturdy and stylish dining chairs, this machine is the perfect solution for all your furniture-making needs.

One of the key features of the SHENZHOU’s Molding Machine is its ability to stack and mold multiple chairs or stools at once, saving you time and labor costs. The machine's windmill design ensures even distribution of plastic material, resulting in flawlessly molded and durable furniture pieces every time.

In addition, the SHENZHOU’s Molding Machine is built to be stackable, making it easy to store and transport. This space-saving design is ideal for manufacturers with limited floor space or those who need to move the machine from one location to another.

But the benefits of the SHENZHOU’s Molding Machine don't stop there. Its user-friendly interface and intuitive controls make it easy to operate, even for beginners. With just a few simple steps, you can start producing high-quality plastic furniture pieces with minimal training and supervision.

Furthermore, the SHENZHOU’s Molding Machine is equipped with safety features to ensure a smooth and secure production process. From automatic shut-off mechanisms to emergency stop buttons, this machine prioritizes the well-being of its operators and the longevity of the equipment.

The SHENZHOU’s Plastic Restaurant Dining Room Chair Stackable Windmill Stool Injection Making Molding Machine is a must-have for anyone in the furniture manufacturing industry. With its advanced technology, user-friendly design, and top-notch performance, this machine is sure to take your production process to the next level. Don't miss out on this opportunity to streamline your operations and produce high-quality plastic furniture with ease. Invest in the SHENZHOU’s Molding Machine today and see the difference it can make for your business

项目 ITEM |

单位UNIT |

SZ—2400A |

|||||||

注射装置 INJECTION UNIT |

|||||||||

螺杆直径 |

SCREW DIAMETER |

mm |

55 |

60 |

65 |

||||

螺杆长径比 |

SCREW LID RATIO |

L/D |

22.9 |

21 |

19.4 |

||||

理论注射容积 |

THEORETICAL SHOT VOLUME |

CM3 |

665 |

791 |

929 |

||||

注射质量 - PS料 |

SHOT WEIGHT - PS |

g |

605 |

720 |

845 |

||||

注射压力 |

INJECTION PRESSURE |

Mpa |

210 |

176 |

150 |

||||

理论注射速率 - PS料 |

THEORETICAL INJECTION RATE - PS |

g/s |

176.5 |

210 |

245 |

||||

塑化能力 - PS料 |

PLASTICISING CAPACITY |

g/s |

26.4 |

32.5 |

40 |

||||

螺杆驱动扭矩 |

SCREW TORQUE |

N/m |

2000 |

||||||

螺杆最高转速 |

MAX. SCREW ROTATE SPEED |

r/min |

150 |

||||||

洼射行程 |

INJECTION STROKE |

mm |

280 |

||||||

合模装置 CLAMPING UNIT |

|||||||||

合模力 |

MAX. CLAMPING FORCE K |

KN |

2400 |

||||||

移模行程 |

MAX. OPENING STROKE |

mm |

530 |

||||||

拉杆有效间距 - VxH |

SPACE BETWEEN TIE BARS |

mm |

555×555 |

||||||

允许模厚 - MIN-MAX |

MOULD HEIGHT |

mm |

200-570 |

||||||

模板最大开距 |

MAX. DAYLIGHT |

mm |

1100 |

||||||

液压顶出力 |

EJECTOR FORCE |

KN |

61.5 |

||||||

液压顶出行程 |

EJECTOR STROKE |

mm |

135 |

||||||

液压顶出杆总数 |

EJECTOR QUANTITY |

9 |

|||||||

其它 OTHER |

|||||||||

油泵电动机功率 |

PUMP MOTOR POWER |

KW |

22 |

||||||

油泵最高压力 |

PUMP PRESSURE |

Mpa |

16 |

||||||

料简加热功率 |

HEATING POWER |

KW |

18.5 |

||||||

加热区段 |

HEATING ZONE |

5 |

|||||||

机器外形 - LxWxH |

SIZE |

m |

6.2×1.6×2.1 |

||||||

机器净重 |

NET WEIGHT |

t |

8.0 |

||||||

油箱容积 |

OIL TANK CAPACITY |

L |

440 |

||||||

国际公认型号 |

INTERNATIONAL DESIGNATION |

2400—1390 |

|||||||

A: Our factory is located in Shenzhou Machinery, No. 22 Zhenbei Road, Fenghuang Town, Zhangjiagang City China. All our clients, from home or abroad, are warmly welcome to visit us