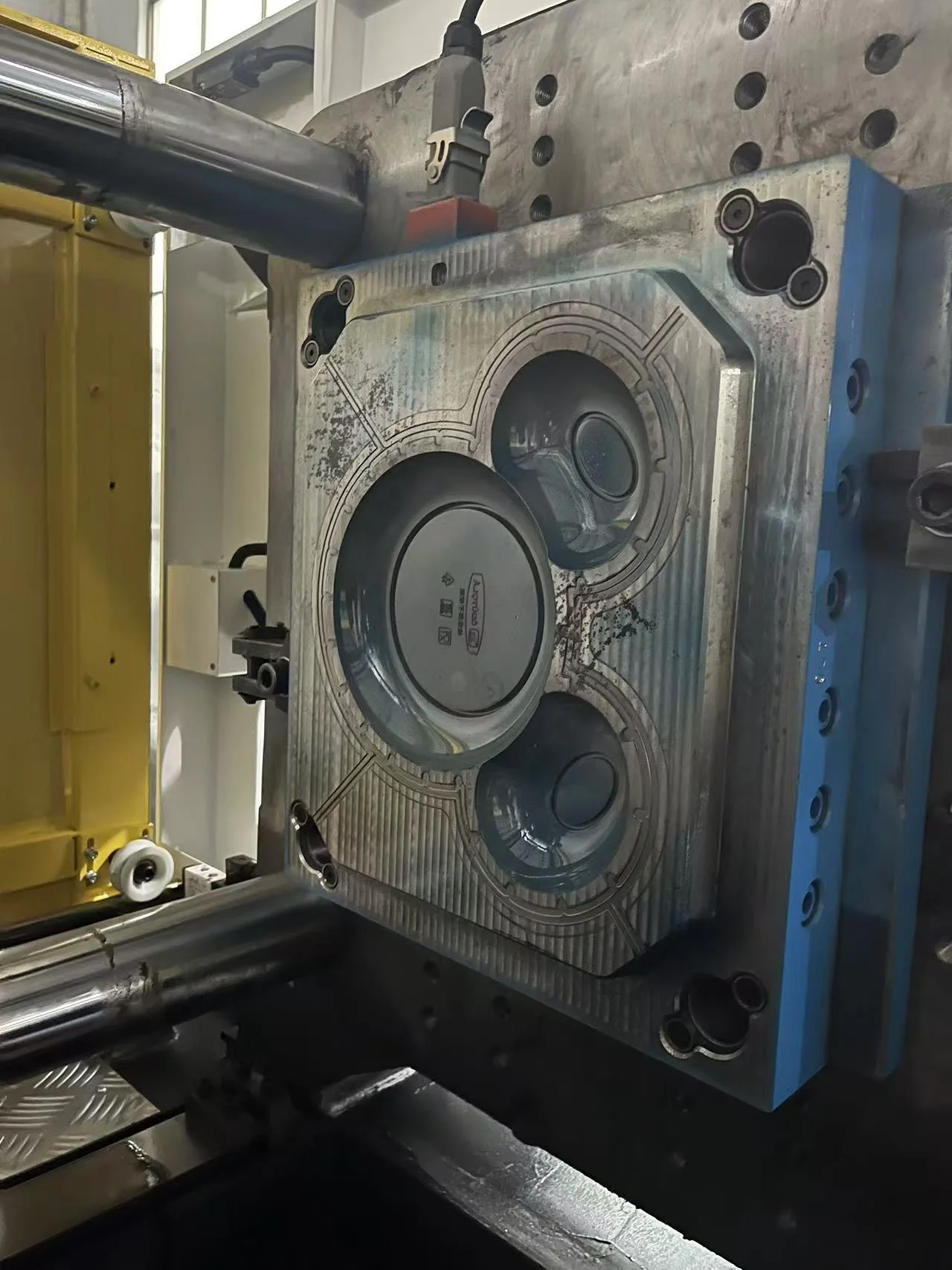

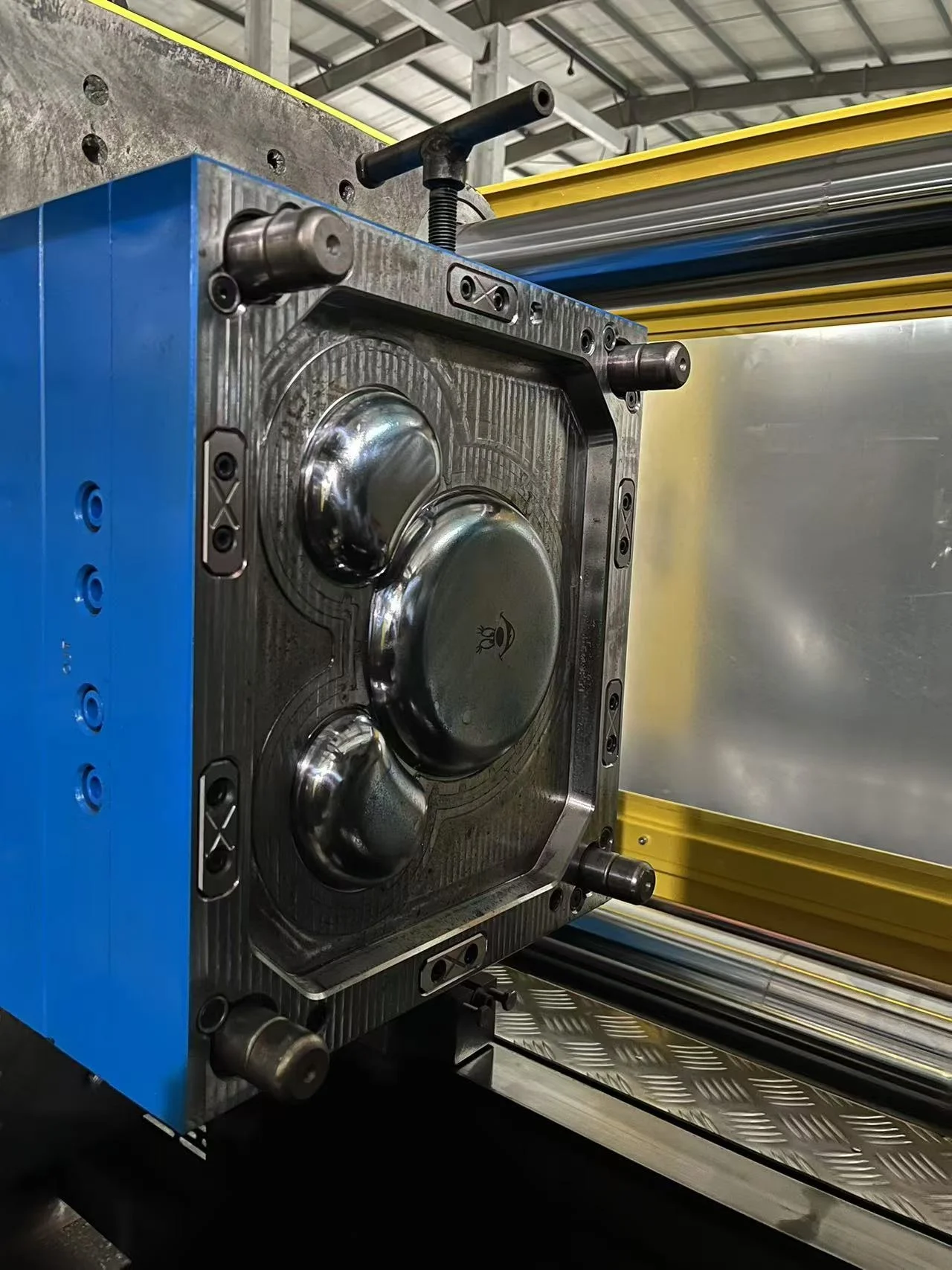

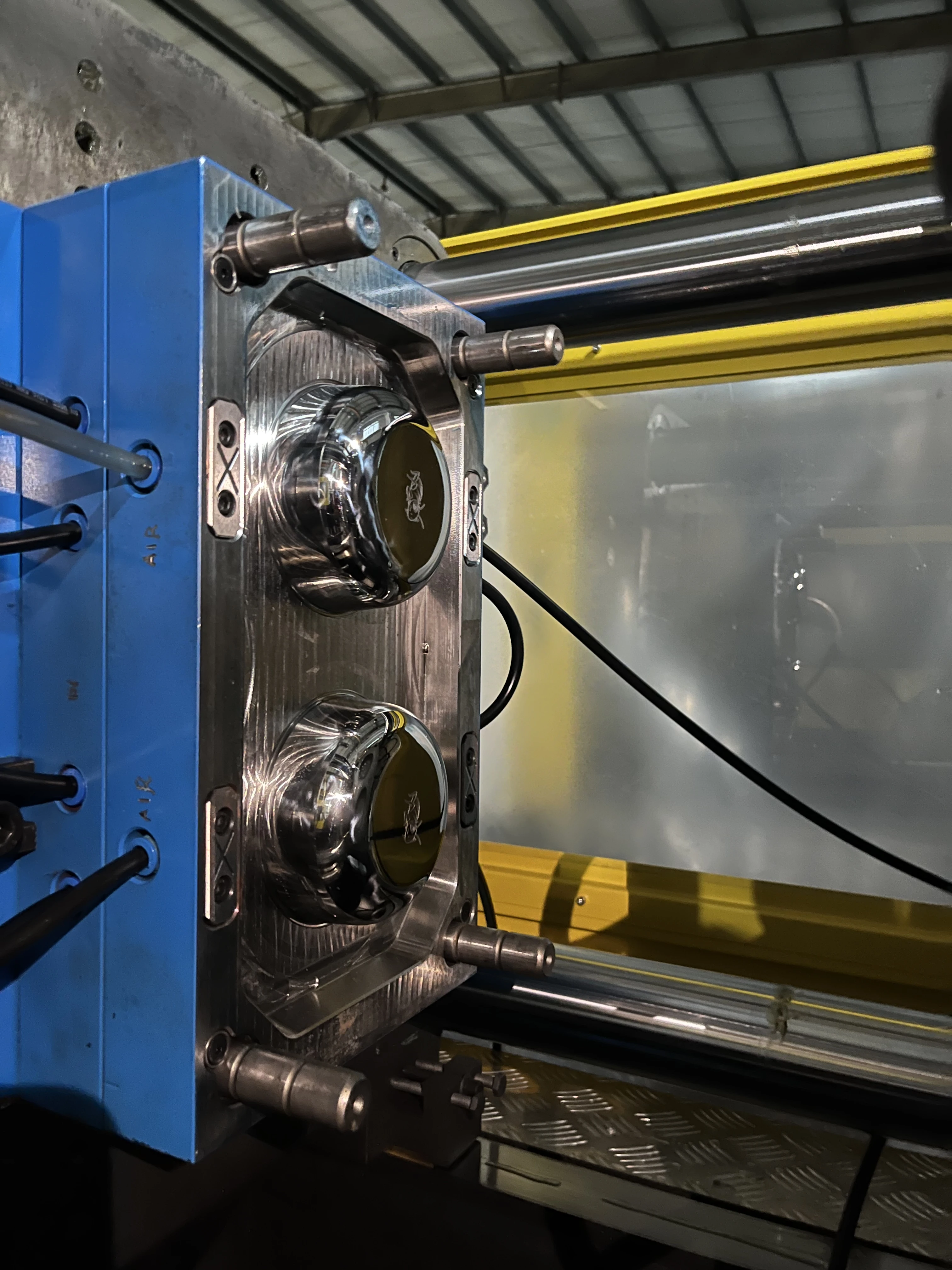

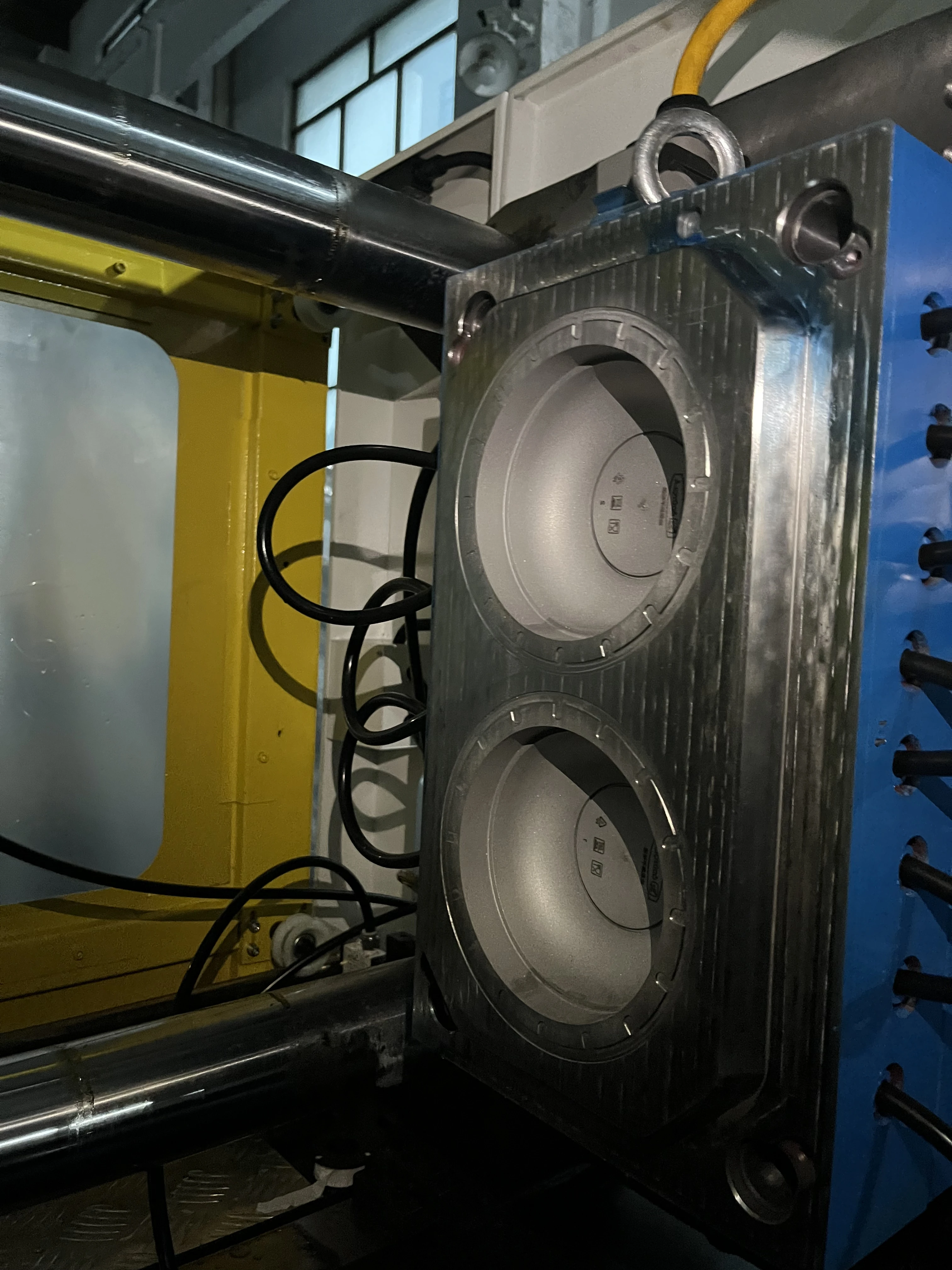

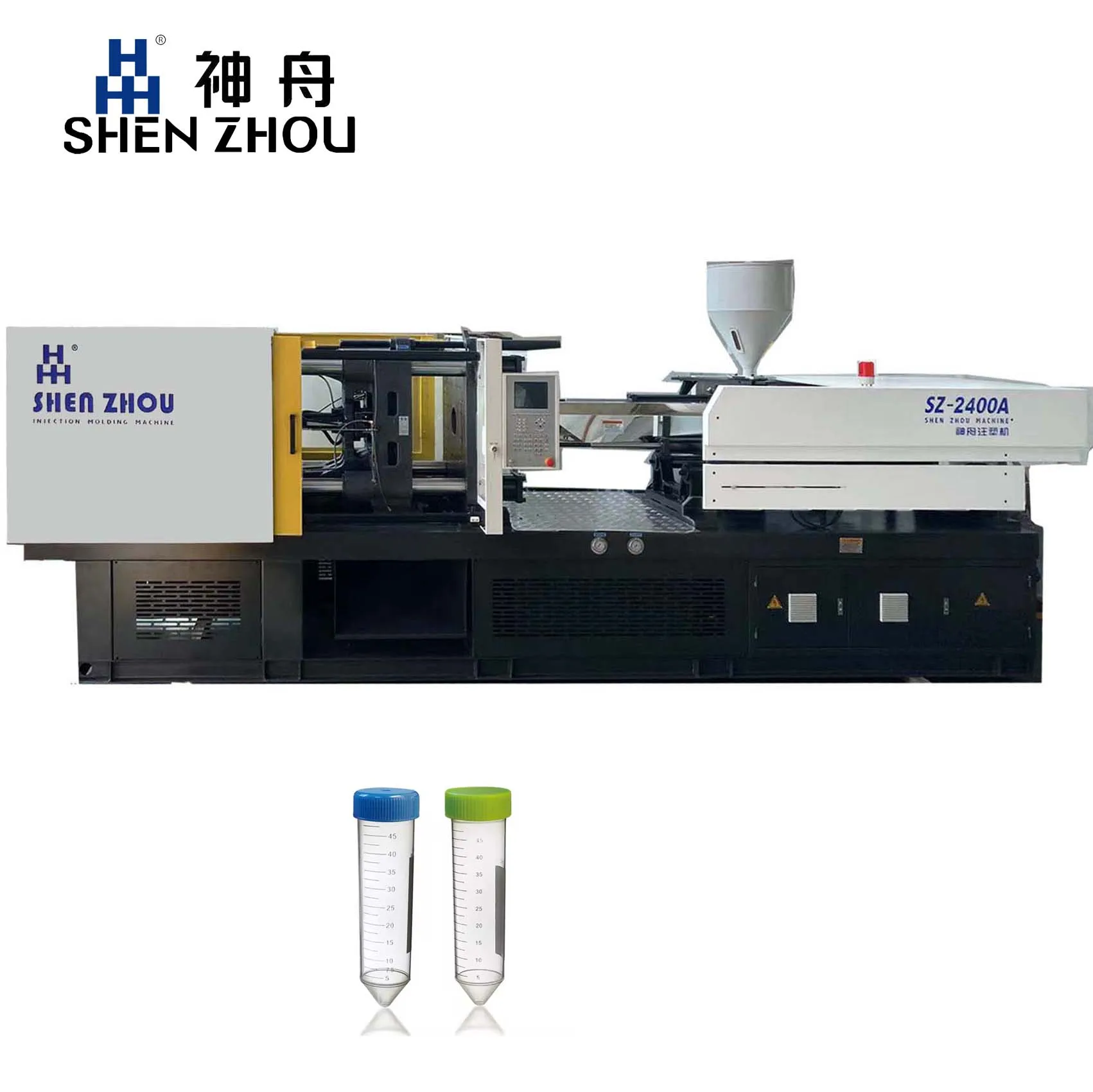

Plastic Reusable Kitchen Straw Food Salad Dessert Soup Bowl Molds Injected Injection Molding Machine

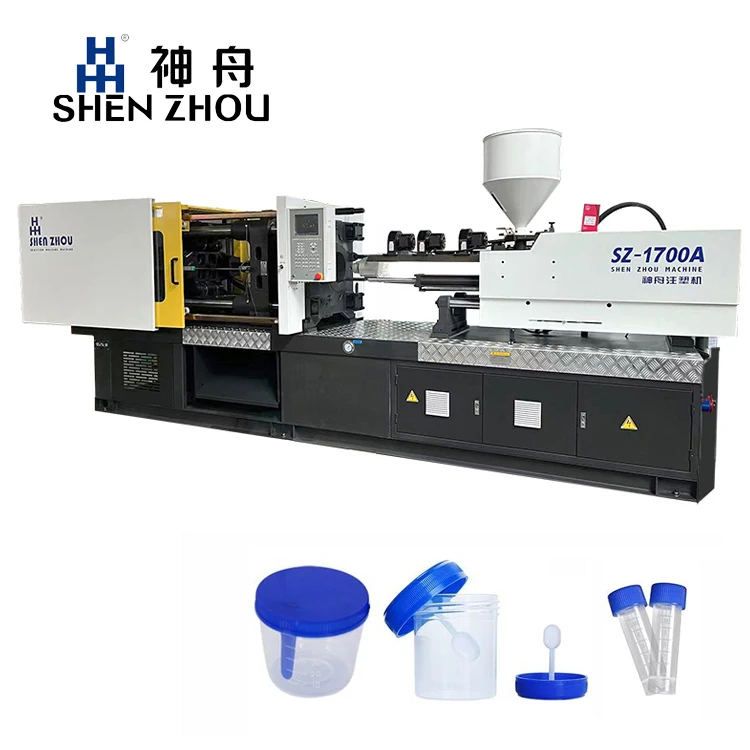

SZ—1700A Injection molding machine.

SCREW DIAMETER (mm) : 50

SCREW LID RATIO (L/D) :21

THEORETICAL SHOT VOLUME (CM3): 442

SHOT WEIGHT(PS) (g): 402

Description

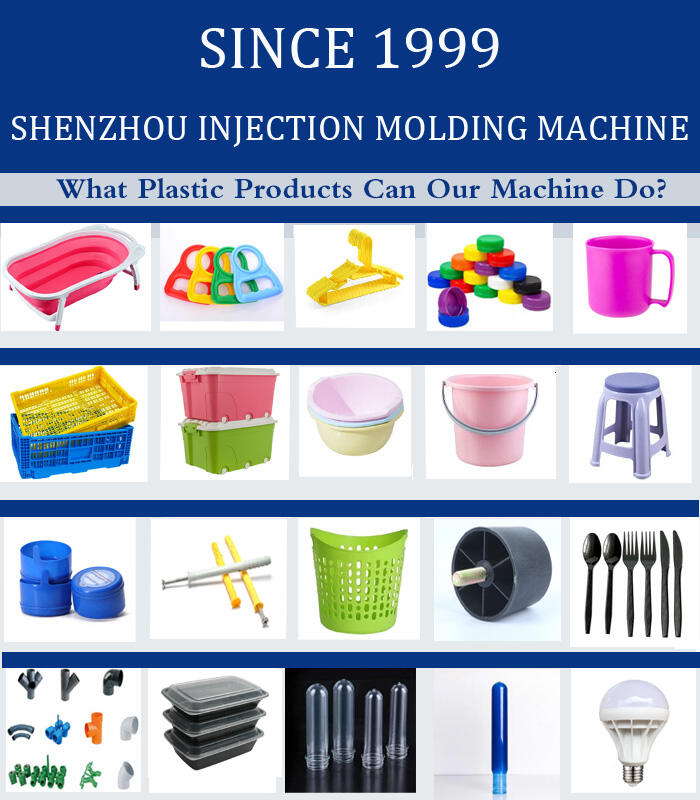

Introducing, the SHENZHOU’s Plastic Reusable Kitchen Straw Food Salad Dessert Soup Bowl Molds Injected Injection Molding Machine, a versatile and essential tool for any kitchen or food service environment.

This innovative machine allows you to easily create plastic reusable straws, food bowls, and molds for salads, desserts, and soups. With its durable construction and precise injection molding technology, the SHENZHOU machine ensures consistent and high-quality results every time.

Say goodbye to disposable plastic products that harm the environment and invest in a sustainable solution with the SHENZHOU’s Molding Machine. By using reusable plastic materials, you can reduce waste and contribute to a greener planet.

Whether you own a restaurant, catering business, or simply want to make your own plastic kitchenware at home, this machine is a perfect choice. It is easy to operate, with intuitive controls and a user-friendly design that make the injection molding process quick and efficient.

The SHENZHOU’s Molding Machine is also highly customizable, allowing you to create a wide variety of shapes and sizes for your plastic products. From sleek and slim straws to large and sturdy food bowls, the possibilities are endless with this versatile machine.

In addition to its practicality and sustainability, the SHENZHOU’s Molding Machine is also built to last. Made from high-quality materials and engineered for durability, you can rely on this machine for years to come.

Upgrade your kitchen or food service operation with the SHENZHOU’s Plastic Reusable Kitchen Straw Food Salad Dessert Soup Bowl Molds Injected Injection Molding Machine. It is the perfect solution for creating reusable plastic products that are environmentally friendly, cost-effective, and convenient to use. Say goodbye to single-use plastics and hello to a more sustainable future with the SHENZHOU’s Molding Machine

项目 ITEM |

单位UNIT |

SZ—2400A |

|||||||

注射装置 INJECTION UNIT |

|||||||||

螺杆直径 |

SCREW DIAMETER |

mm |

55 |

60 |

65 |

||||

螺杆长径比 |

SCREW LID RATIO |

L/D |

22.9 |

21 |

19.4 |

||||

理论注射容积 |

THEORETICAL SHOT VOLUME |

CM3 |

665 |

791 |

929 |

||||

注射质量 - PS料 |

SHOT WEIGHT - PS |

g |

605 |

720 |

845 |

||||

注射压力 |

INJECTION PRESSURE |

Mpa |

210 |

176 |

150 |

||||

理论注射速率 - PS料 |

THEORETICAL INJECTION RATE - PS |

g/s |

176.5 |

210 |

245 |

||||

塑化能力 - PS料 |

PLASTICISING CAPACITY |

g/s |

26.4 |

32.5 |

40 |

||||

螺杆驱动扭矩 |

SCREW TORQUE |

N/m |

2000 |

||||||

螺杆最高转速 |

MAX. SCREW ROTATE SPEED |

r/min |

150 |

||||||

洼射行程 |

INJECTION STROKE |

mm |

280 |

||||||

合模装置 CLAMPING UNIT |

|||||||||

合模力 |

MAX. CLAMPING FORCE K |

KN |

2400 |

||||||

移模行程 |

MAX. OPENING STROKE |

mm |

530 |

||||||

拉杆有效间距 - VxH |

SPACE BETWEEN TIE BARS |

mm |

555×555 |

||||||

允许模厚 - MIN-MAX |

MOULD HEIGHT |

mm |

200-570 |

||||||

模板最大开距 |

MAX. DAYLIGHT |

mm |

1100 |

||||||

液压顶出力 |

EJECTOR FORCE |

KN |

61.5 |

||||||

液压顶出行程 |

EJECTOR STROKE |

mm |

135 |

||||||

液压顶出杆总数 |

EJECTOR QUANTITY |

9 |

|||||||

其它 OTHER |

|||||||||

油泵电动机功率 |

PUMP MOTOR POWER |

KW |

22 |

||||||

油泵最高压力 |

PUMP PRESSURE |

Mpa |

16 |

||||||

料简加热功率 |

HEATING POWER |

KW |

18.5 |

||||||

加热区段 |

HEATING ZONE |

5 |

|||||||

机器外形 - LxWxH |

SIZE |

m |

6.2×1.6×2.1 |

||||||

机器净重 |

NET WEIGHT |

t |

8.0 |

||||||

油箱容积 |

OIL TANK CAPACITY |

L |

440 |

||||||

国际公认型号 |

INTERNATIONAL DESIGNATION |

2400—1390 |

|||||||

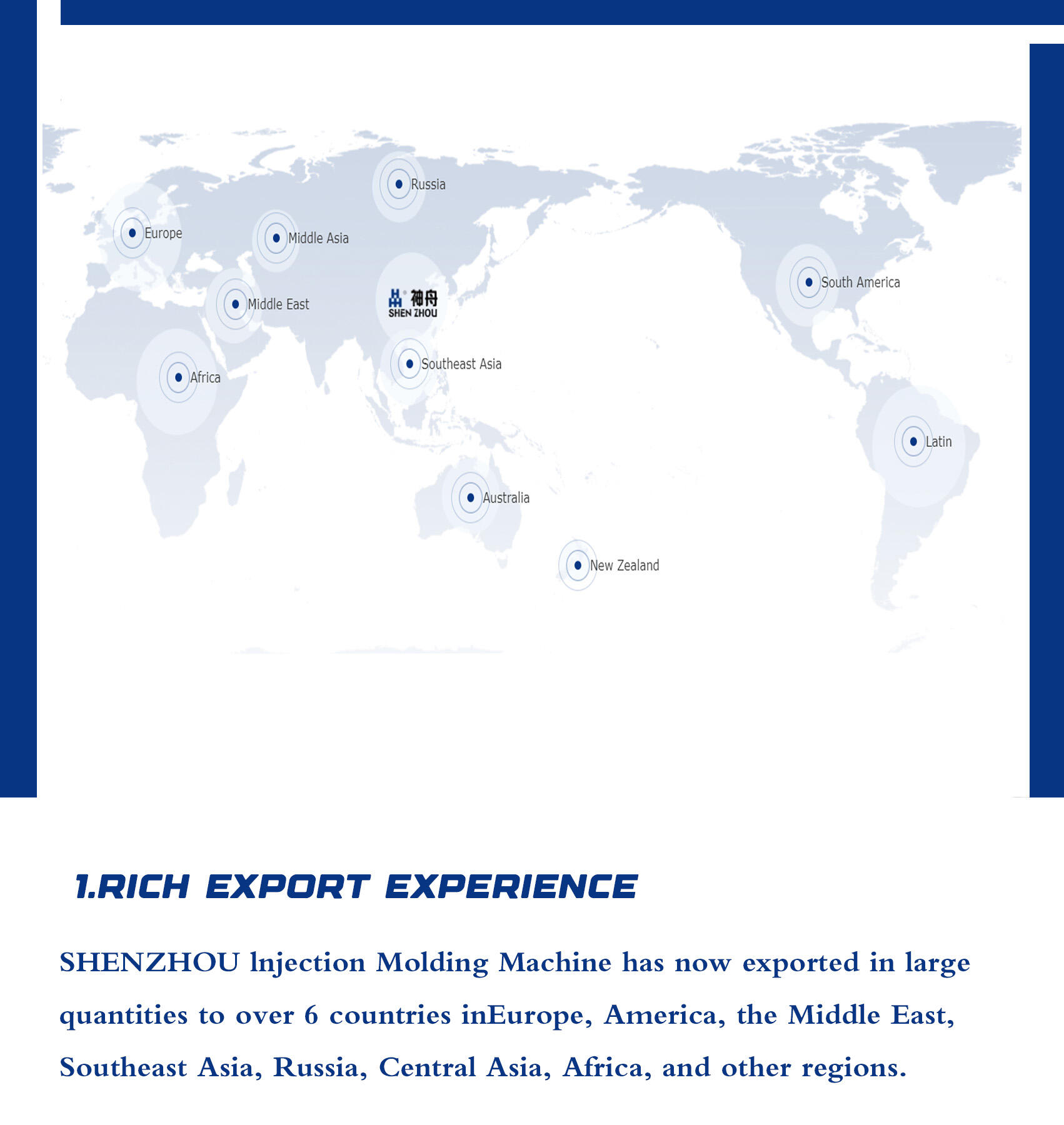

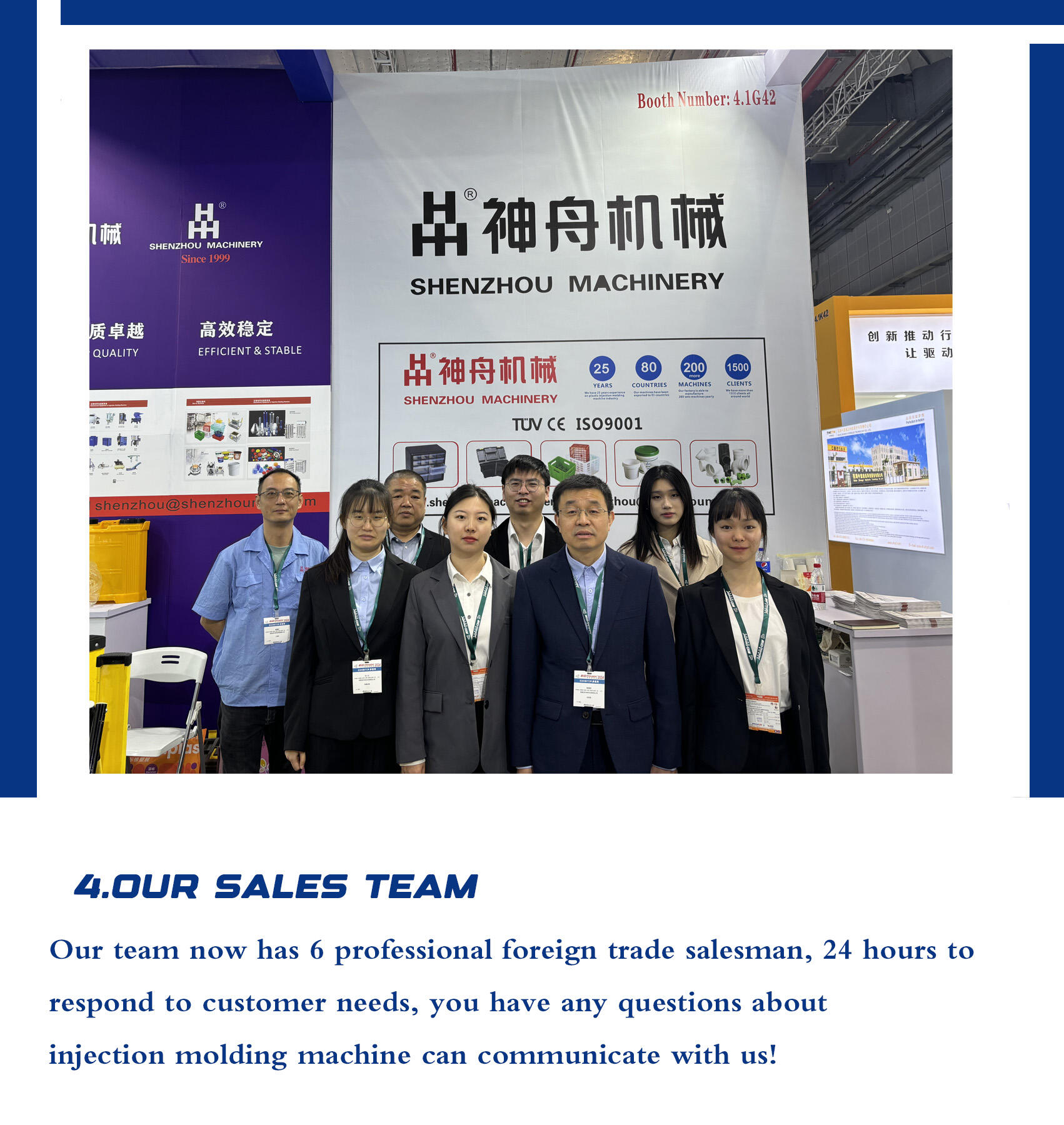

A: Our factory is located in Shenzhou Machinery, No. 22 Zhenbei Road, Fenghuang Town, Zhangjiagang City China. All our clients, from home or abroad, are warmly welcome to visit us