Plastic Smooth Surface Lotion Pump Aluminium and PP Foaming Soap Dispenser Injection Molding Machines

|

ITEM |

UNIT |

SZ—5500A |

||

|

INJECTION UNIT |

|

|

||

|

SCREW DIAMETER |

mm |

80 |

85 |

90 |

|

SCREW LID RATIO |

L/D |

22.3 |

21 |

19.8 |

|

THEORETICAL SHOT VOLUME |

CM3 |

2141 |

2418 |

2710 |

|

SHOT WEIGHT(PS) |

g |

1948 |

2200 |

2466 |

|

INJECTION PRESSURE |

Mpa |

188 |

167 |

149 |

|

THEORETICAL INJECTION RATE(PS) |

g/s |

427 |

482 |

541 |

|

PLASTICISING CAPACITY |

g/s |

80 |

100 |

118 |

|

SCREW TORQUE |

N.m |

5170 |

||

|

MAX.SCREW ROTATE SPEED |

r/min |

150 |

||

|

INJECTION STROKE |

mm |

425 |

||

|

CLAMPING UNIT |

|

|||

|

MAX.CLAMPING FORCE K |

KN |

5500 |

||

|

MAX.OPENING STROKE |

mm |

820 |

||

|

SPACE BETWEEN TIE BARS |

mm |

810×810 |

||

|

MOULD HEIGHT |

mm |

350-820 |

||

|

MAX.DAYLIGHT |

mm |

1640 |

||

|

EJECTOR FORCE |

KN |

150 |

||

|

EJECTOR STROKE |

mm |

210 |

||

|

EJECTOR QUANTITY |

|

13 |

||

Description

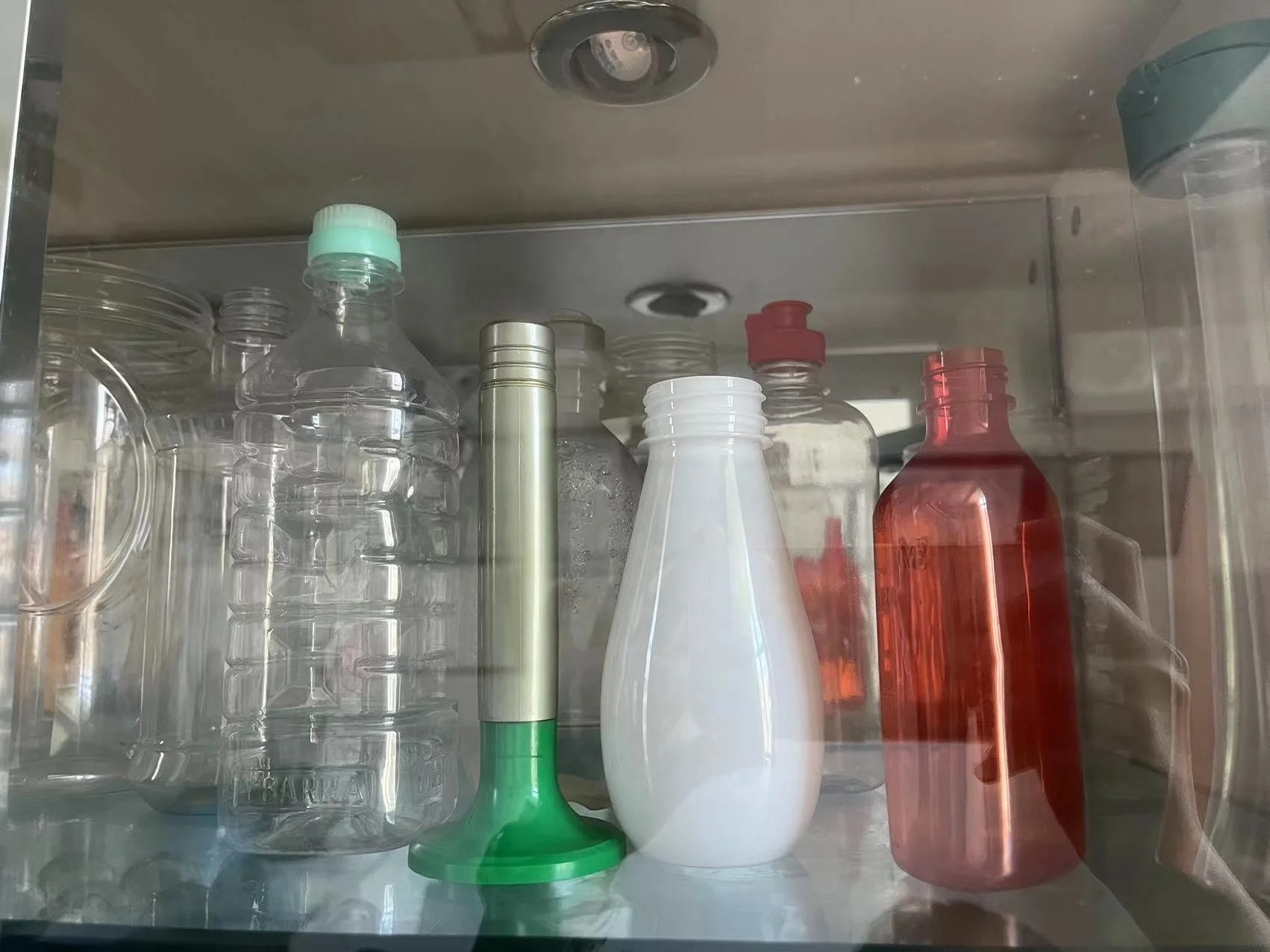

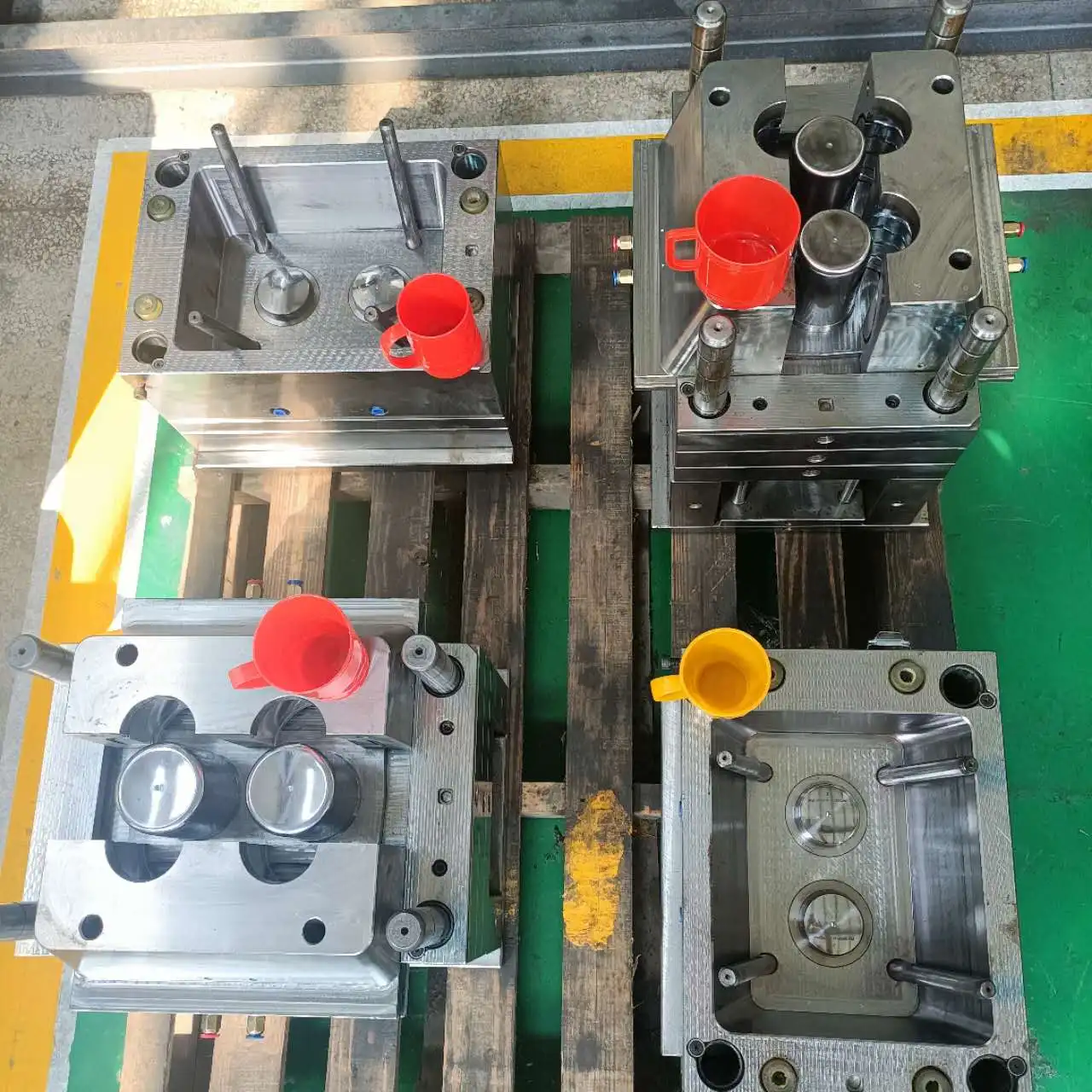

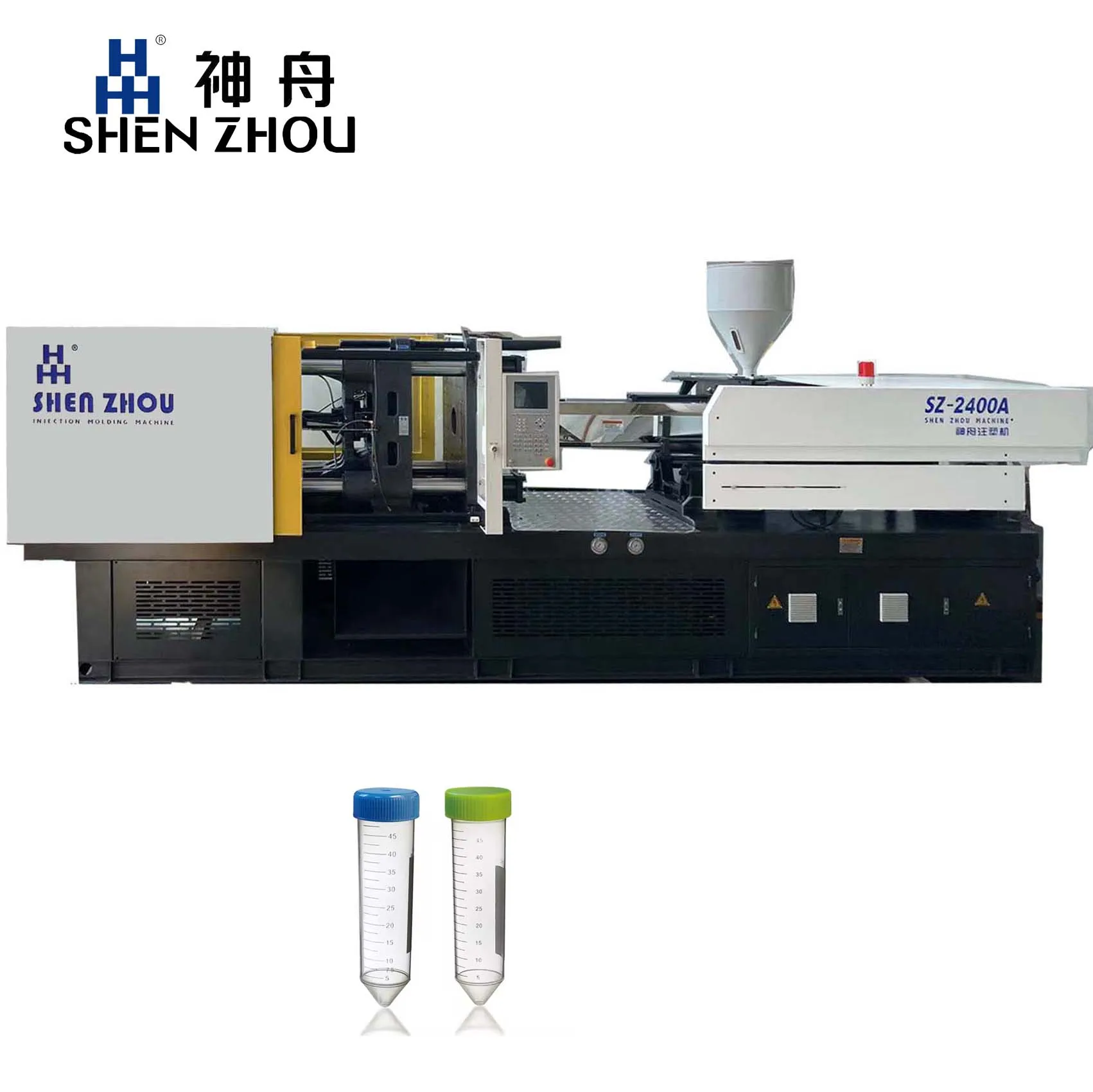

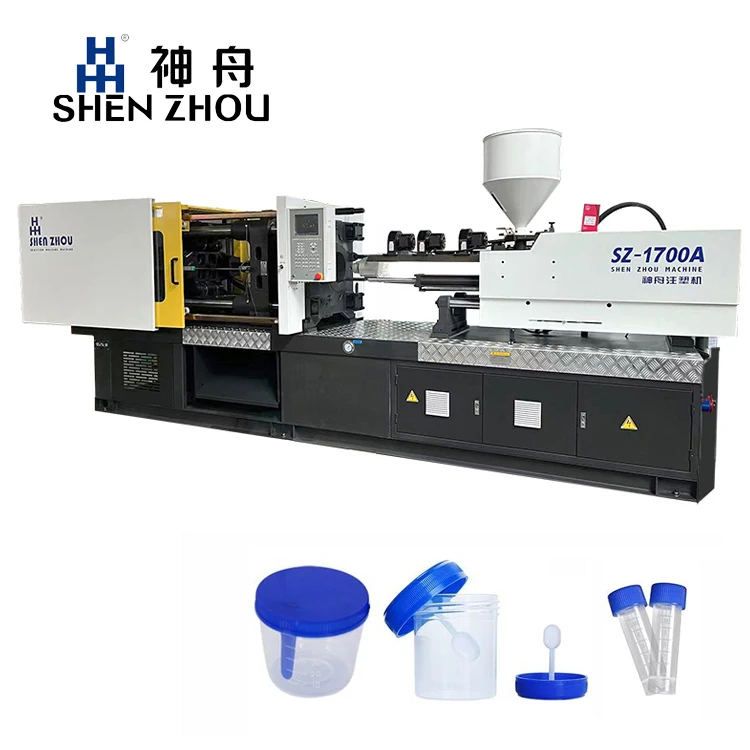

Introducing, the SHENZHOU’s Plastic Smooth Surface Lotion Pump Aluminium and PP Foaming Soap Dispenser Injection Molding Machines – the perfect solution for producing high-quality lotion pumps and soap dispensers with ease.

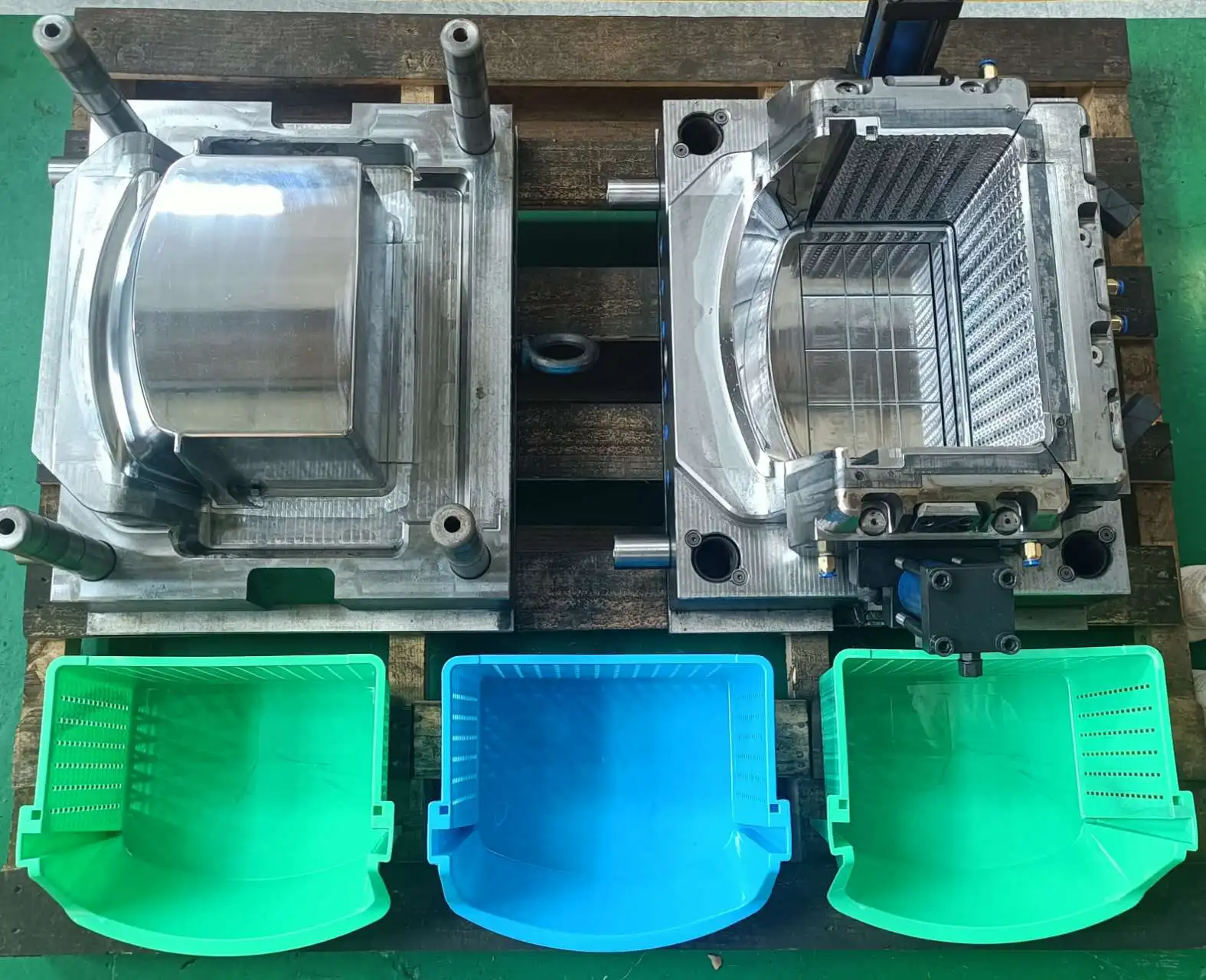

These state-of-the-art machines are designed to provide smooth and precise injection molding, ensuring consistent and reliable results every time. The plastic smooth surface design ensures a seamless finish for your lotion pumps and soap dispensers, giving them a professional and polished look.

The SHENZHOU machines are equipped with advanced technology and features that make them easy to operate and maintain. The aluminium and PP materials used in the construction of these machines are durable and long-lasting, ensuring that your investment will stand the test of time.

Whether you are a small or large-scale manufacturer, the SHENZHOU’s Plastic Smooth Surface Lotion Pump Aluminium and PP Foaming Soap Dispenser Injection Molding Machines are designed to meet your production needs. These machines are versatile and can be used to create a wide range of lotion pumps and soap dispensers, making them ideal for a variety of industries such as cosmetics, personal care, and household products.

With their efficient and reliable performance, these machines can help increase your production capacity and streamline your manufacturing processes. The foaming soap dispenser feature allows you to create foam soap products, which are popular among consumers for their convenience and effectiveness.

The SHENZHOU brand is known for its high-quality products and innovative solutions in the injection molding industry. With these Plastic Smooth Surface Lotion Pump Aluminium and PP Foaming Soap Dispenser Injection Molding Machines, SHENZHOU continues to uphold its reputation for excellence and reliability.

The SHENZHOU’s Plastic Smooth Surface Lotion Pump Aluminium and PP Foaming Soap Dispenser Injection Molding Machines are the perfect choice for manufacturers looking to produce top-quality lotion pumps and soap dispensers efficiently and effectively. Invest in a SHENZHOU machine today and take your production to the next level

项目 ITEM |

单位UNIT |

SZ—2000A |

|||||||

注射装置 INJECTION UNIT |

|||||||||

螺杆直径 |

SCREW DIAMETER |

mm |

50 |

55 |

60 |

||||

螺杆长径比 |

SCREW LID RATIO |

L/D |

23.1 |

21 |

19.3 |

||||

理论注射容积 |

THEORETICAL SHOT VOLUME |

CM3 |

491 |

594 |

707 |

||||

注射质量 - PS料 |

SHOT WEIGHT - PS |

g |

447 |

540 |

643 |

||||

注射压力 |

INJECTION PRESSURE |

Mpa |

215 |

178 |

149 |

||||

理论注射速率 - PS料 |

THEORETICAL INJECTION RATE - PS |

g/s |

145 |

175 |

208 |

||||

塑化能力 - PS料 |

PLASTICISING CAPACITY |

g/s |

22.5 |

28.7 |

35.4 |

||||

螺杆驱动扭矩 |

SCREW TORQUE |

N/m |

1510 |

||||||

螺杆最高转速 |

MAX. SCREW ROTATE SPEED |

r/min |

170 |

||||||

洼射行程 |

INJECTION STROKE |

mm |

250 |

||||||

合模装置 CLAMPING UNIT |

|||||||||

合模力 |

MAX. CLAMPING FORCE K |

KN |

2000 |

||||||

移模行程 |

MAX. OPENING STROKE |

mm |

500 |

||||||

拉杆有效间距 - VxH |

SPACE BETWEEN TIE BARS |

mm |

505×505 |

||||||

允许模厚 - MIN-MAX |

MOULD HEIGHT |

mm |

190-530 |

||||||

模板最大开距 |

MAX. DAYLIGHT |

mm |

1030 |

||||||

液压顶出力 |

EJECTOR FORCE |

KN |

53.1 |

||||||

液压顶出行程 |

EJECTOR STROKE |

mm |

125 |

||||||

液压顶出杆总数 |

EJECTOR QUANTITY |

5 |

|||||||

其它 OTHER |

|||||||||

油泵电动机功率 |

PUMP MOTOR POWER |

KW |

18.5 |

||||||

油泵最高压力 |

PUMP PRESSURE |

Mpa |

16 |

||||||

料简加热功率 |

HEATING POWER |

KW |

16.6 |

||||||

加热区段 |

HEATING ZONE |

4 |

|||||||

机器外形 - LxWxH |

SIZE |

m |

5.9×1.5×2 |

||||||

机器净重 |

NET WEIGHT |

t |

6.8 |

||||||

油箱容积 |

OIL TANK CAPACITY |

L |

420 |

||||||

国际公认型号 |

INTERNATIONAL DESIGNATION |

2000—1060 |

|||||||

A: Our factory is located in Shenzhou Machinery, No. 22 Zhenbei Road, Fenghuang Town, Zhangjiagang City China. All our clients, from home or abroad, are warmly welcome to visit us