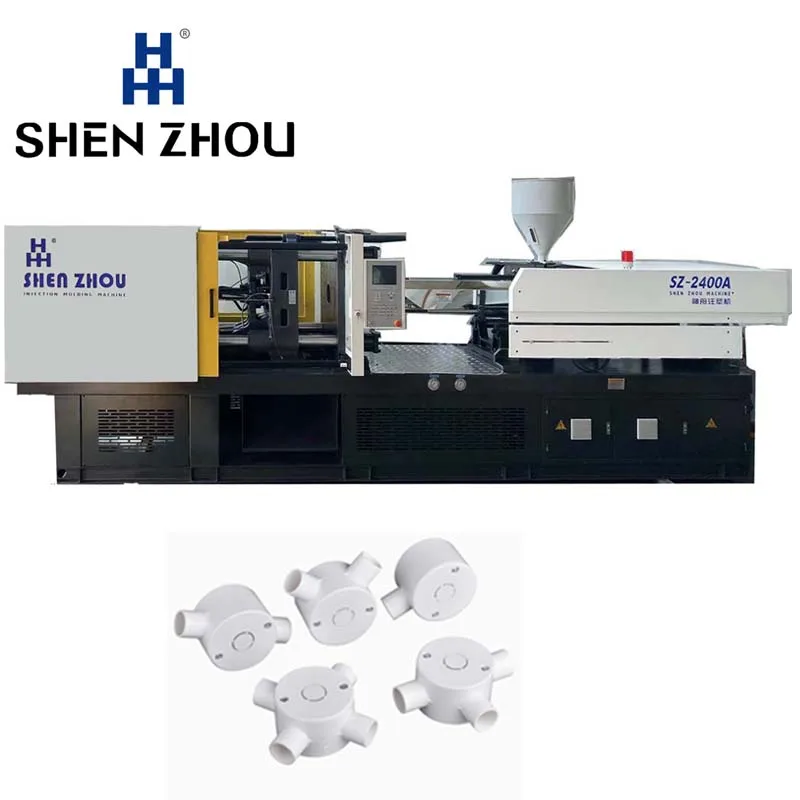

Plastic Wholesale Box U Type 2 Way 3 Way Pvc Pipe Fittings Electrical Cable Junction Box Injection Molding Machine

Description

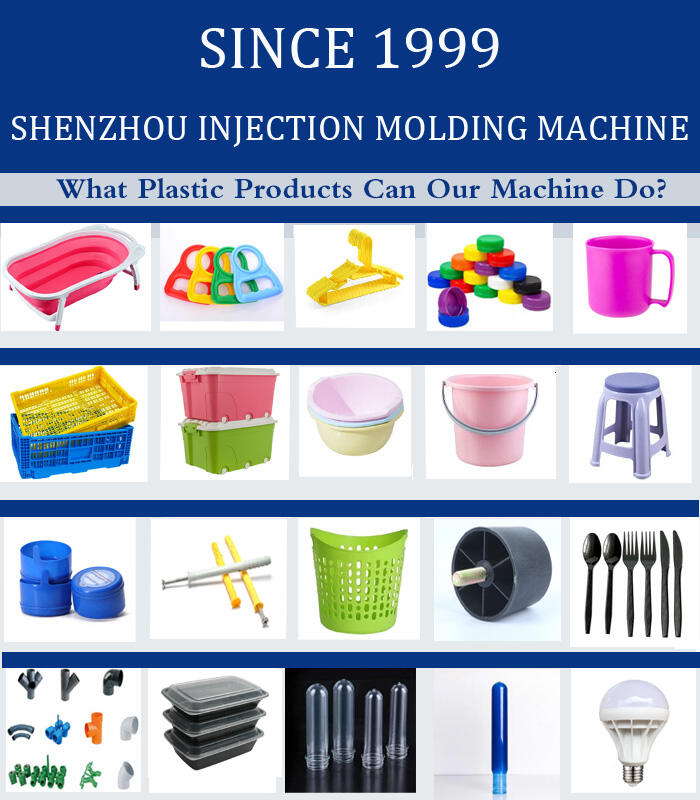

Introducing, the SHENZHOU’s Plastic Wholesale Box U Type 2 Way 3 Way PVC Pipe Fittings Electrical Cable Junction Box Injection Molding Machine - a must-have tool for any professional in the electrical or plumbing industry.

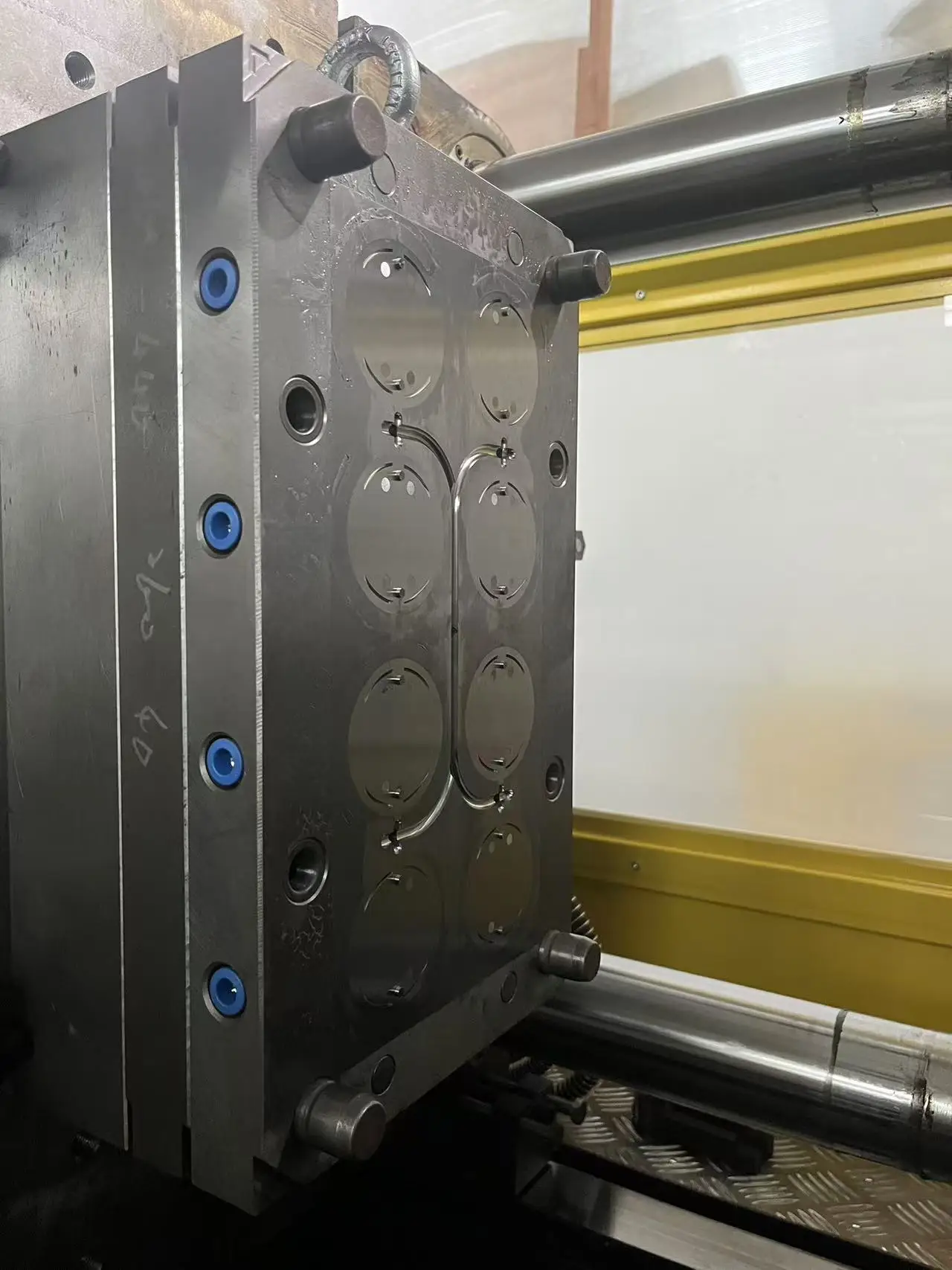

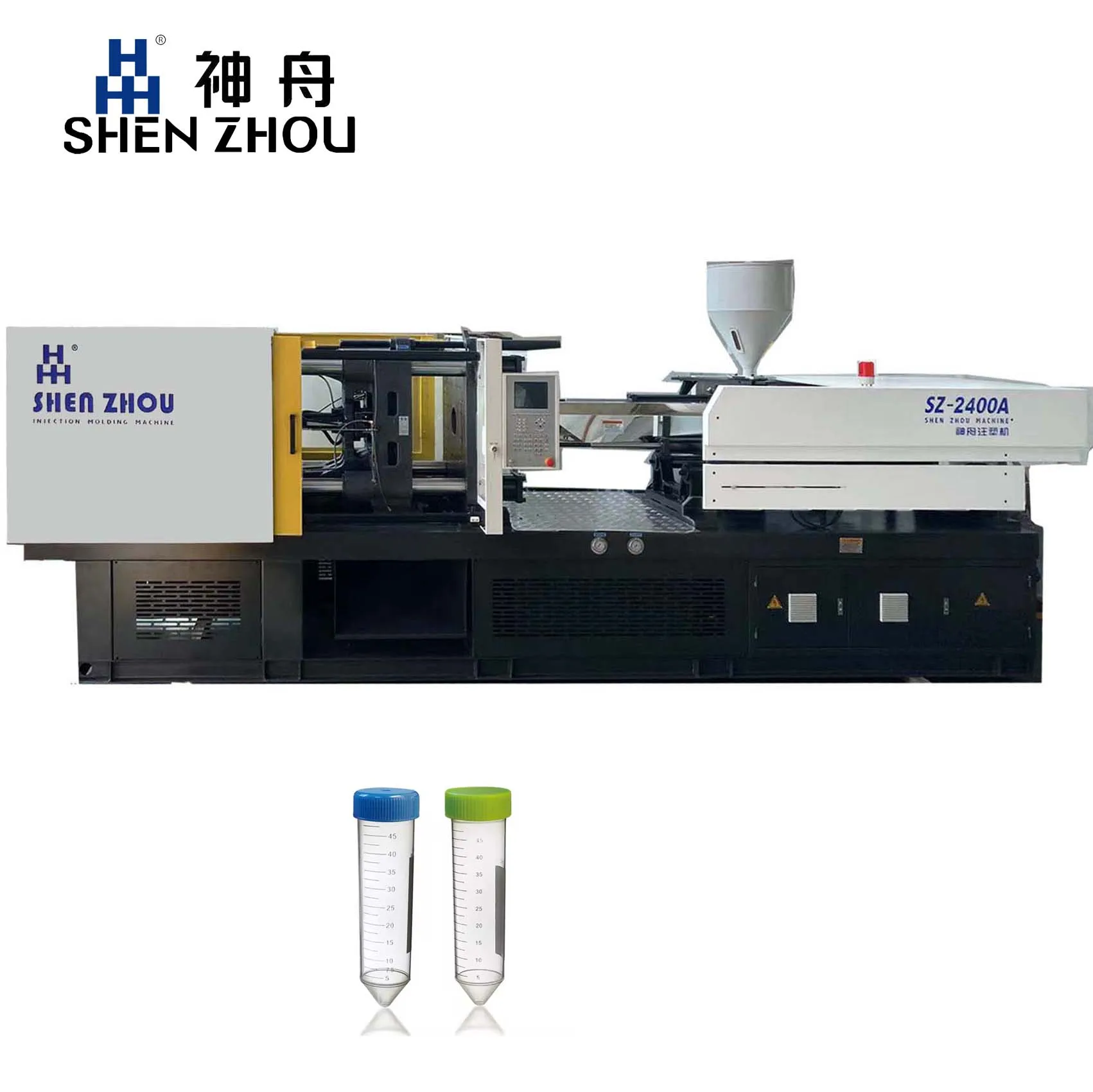

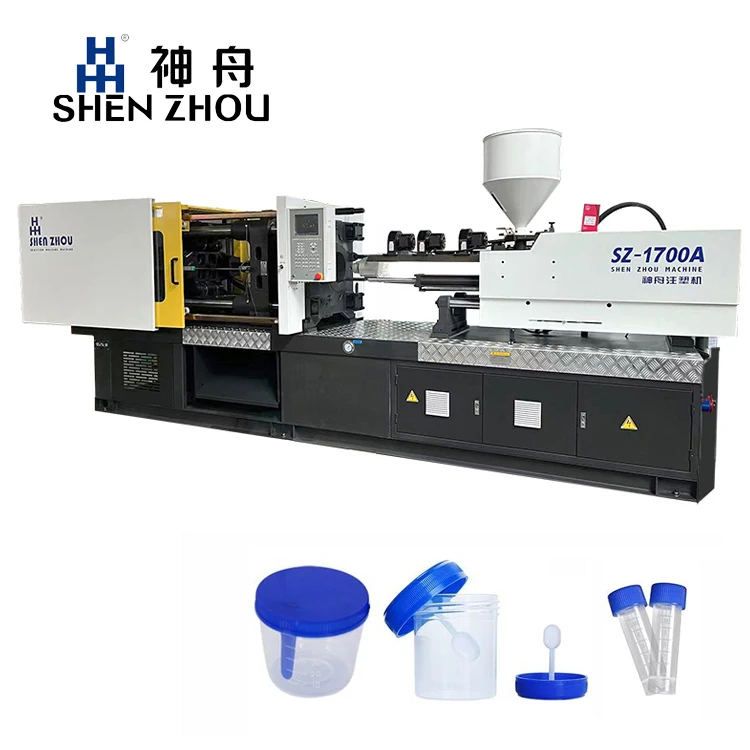

This versatile machine is designed to efficiently produce high-quality plastic wholesale boxes, U type fittings, 2 way fittings, 3 way fittings, PVC pipe fittings, electrical cable junction boxes, and more. With its advanced technology and precision engineering, the SHENZHOU’s Injection Molding Machine ensures that each product is consistently molded to perfection.

Manufactured by the renowned brand SHENZHOU, this machine is built to last and can withstand heavy use in demanding industrial environments. Its durable construction and reliable performance make it a top choice for businesses looking to increase efficiency and productivity in their operations.

Whether you are a contractor, electrician, plumber, or industrial manufacturer, the SHENZHOU’s Injection Molding Machine is a valuable asset that can help streamline your production process. It is easy to use and offers a wide range of customization options to meet your specific requirements.

The machine features a user-friendly interface, making it simple to set up and operate. Its high-speed injection molding capabilities ensure quick and efficient production times, saving you time and money in the long run.

In addition, the SHENZHOU’s Injection Molding Machine is energy-efficient, helping reduce your carbon footprint and lower operating costs. Its compact design also makes it easy to transport and install in any workspace.

When it comes to quality and reliability, the SHENZHOU’s Plastic Wholesale Box U Type 2 Way 3 Way PVC Pipe Fittings Electrical Cable Junction Box Injection Molding Machine is unmatched. Invest in this top-of-the-line machine today and take your business to the next level

项目 ITEM |

单位UNIT |

SZ—2400A |

|||||||

注射装置 INJECTION UNIT |

|||||||||

螺杆直径 |

SCREW DIAMETER |

mm |

55 |

60 |

65 |

||||

螺杆长径比 |

SCREW LID RATIO |

L/D |

22.9 |

21 |

19.4 |

||||

理论注射容积 |

THEORETICAL SHOT VOLUME |

CM3 |

665 |

791 |

929 |

||||

注射质量 - PS料 |

SHOT WEIGHT - PS |

g |

605 |

720 |

845 |

||||

注射压力 |

INJECTION PRESSURE |

Mpa |

210 |

176 |

150 |

||||

理论注射速率 - PS料 |

THEORETICAL INJECTION RATE - PS |

g/s |

176.5 |

210 |

245 |

||||

塑化能力 - PS料 |

PLASTICISING CAPACITY |

g/s |

26.4 |

32.5 |

40 |

||||

螺杆驱动扭矩 |

SCREW TORQUE |

N/m |

2000 |

||||||

螺杆最高转速 |

MAX. SCREW ROTATE SPEED |

r/min |

150 |

||||||

洼射行程 |

INJECTION STROKE |

mm |

280 |

||||||

合模装置 CLAMPING UNIT |

|||||||||

合模力 |

MAX. CLAMPING FORCE K |

KN |

2400 |

||||||

移模行程 |

MAX. OPENING STROKE |

mm |

530 |

||||||

拉杆有效间距 - VxH |

SPACE BETWEEN TIE BARS |

mm |

555×555 |

||||||

允许模厚 - MIN-MAX |

MOULD HEIGHT |

mm |

200-570 |

||||||

模板最大开距 |

MAX. DAYLIGHT |

mm |

1100 |

||||||

液压顶出力 |

EJECTOR FORCE |

KN |

61.5 |

||||||

液压顶出行程 |

EJECTOR STROKE |

mm |

135 |

||||||

液压顶出杆总数 |

EJECTOR QUANTITY |

9 |

|||||||

其它 OTHER |

|||||||||

油泵电动机功率 |

PUMP MOTOR POWER |

KW |

22 |

||||||

油泵最高压力 |

PUMP PRESSURE |

Mpa |

16 |

||||||

料简加热功率 |

HEATING POWER |

KW |

18.5 |

||||||

加热区段 |

HEATING ZONE |

5 |

|||||||

机器外形 - LxWxH |

SIZE |

m |

6.2×1.6×2.1 |

||||||

机器净重 |

NET WEIGHT |

t |

8.0 |

||||||

油箱容积 |

OIL TANK CAPACITY |

L |

440 |

||||||

国际公认型号 |

INTERNATIONAL DESIGNATION |

2400—1390 |

|||||||

A: Our factory is located in Shenzhou Machinery, No. 22 Zhenbei Road, Fenghuang Town, Zhangjiagang City China. All our clients, from home or abroad, are warmly welcome to visit us