Advantages of Blow Molding for Pet Bottle Production

Benefits of Blow Molding for Pet Bottles You will find various factors at play when it comes to blow-molding in relation to pet-bottle producing.

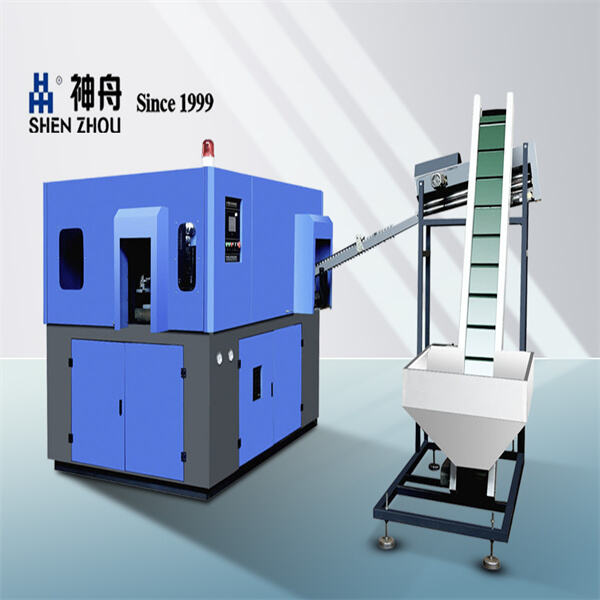

For the production of pet bottle, blow molding has many advantages. It enables us to make bottles in varying shapes and sizes, which in turn would allow us to personalize them for different uses. The process also yields lighter bottles, which are more cost-efficient to ship and better for the environment. Besides, blow molding to produce bottles is a quick and convenient way, with fast and efficient capacity to meet high quantity of pet bottles by SHENZHOU.