Description

Technical Parameter

|

NO |

ITEM |

UNIT |

IBM35 |

IBM45 |

IBM65 |

IBM75 |

|

1 |

Diameter of screw |

MM |

40 |

45 |

50 |

50 |

|

2 |

Injection weight |

G |

176 |

260 |

314 |

400 |

|

3 |

Heating capacity |

KW |

7.2 |

10 |

10 |

12 |

|

4 |

Control area of electric heating |

QTY |

3 |

3 |

3 |

5 |

|

5 |

Clamping force of injection |

KN |

350 |

450 |

650 |

750 |

|

6 |

Clamping force of blow |

KN |

40 |

78 |

89 |

150 |

|

7 |

Opening stroke of mold platen |

MM |

120 |

120 |

140 |

140 |

|

8 |

Injector stroke |

MM |

220 |

220 |

220 |

220 |

|

9 |

Max. plate size of die(L*W) |

MM |

420*340 |

580*390 |

740*390 |

840*460 |

|

10 |

Min. dia. thickness(H) |

MM |

180 |

240 |

280 |

280 |

|

11 |

Motor power |

KW |

11/15 |

18.7/22 |

17&22/30 |

18.7&23/30 |

|

12 |

Heating capacity of mould |

KW |

2.8 |

4.0 |

5.0 |

6.0 |

|

13 |

Pressure of hydraulics system |

MPA |

14 |

14 |

14 |

14 |

|

14 |

Min.workingpressure of compressed air |

MPA |

0.8 |

1.0 |

1.0 |

1.0 |

|

15 |

Discharge rate of compressed air |

M3/mi n |

≥0.7 |

≥0.8 |

≥0.8 |

≥0.8 |

|

16 |

Consumption of cooling water |

M3/hr |

3 |

3 |

3 |

3 |

|

17 |

Dimension of machine (L*W*H) |

MM |

3100*1200*2 200 |

3500*1400*2 300 |

4000*1280*2 350 |

4000*1700*200 0 |

|

18 |

Machine weight |

T |

3.6 |

5.5 |

6.5 |

10 |

|

19 |

Suitable bottle Range |

ML |

3-600 |

5-600 |

5-800 |

5-1000 |

|

20 |

Max. Height of bottle |

MM |

≤175 |

≤200 |

≤200 |

≤200 |

|

21 |

Max. dia. of the bottle |

MM |

≤75 |

≤80 |

≤80 |

≤100 |

|

22 |

Total power |

KW |

25 |

35 |

45 |

50 |

Our advantages

1. The clamping framework adopts single-crossbeam, double poles, which enlarge the space of seting mould, much easier to install mould.

2. Unique PREFlLL technology and variable displacement pump pressurizing technology are applied to hydrauic system to achieve high eficiency and more reliable.

3. Specialized control system: Adapting the specilied controler and software, after completion of machine's commission and parameter seting, all theselled parameters can make use of SD card for storage and re-installinto other machines, it is realy veny convenience for function testing and afelservice.

4. Eneroy saving: Refer to our testing resul, this svstem can save minimum 35% of eneray consumption at any machine. And also it can joint togetheiwth special boards and software instaled to achieve the totally energy consumption and unit product energy consumption, and help the customers to understand the production cost.

5. Stripper station adopts long-distance digital laser sensor for detection, to protect mould safety.

6. Stripper station installs light curtain, to protect personal safety.

7. Optional servo rotary, (Patented product ,patent number:2L2014 2 0196619.X) precise, long using time, easy maintenance, save energy.

8. Optional iniection with all-electric way, replacing hvdraulic way (Practical patent products, patent number: 150582G0287N).

9. CE certificate.

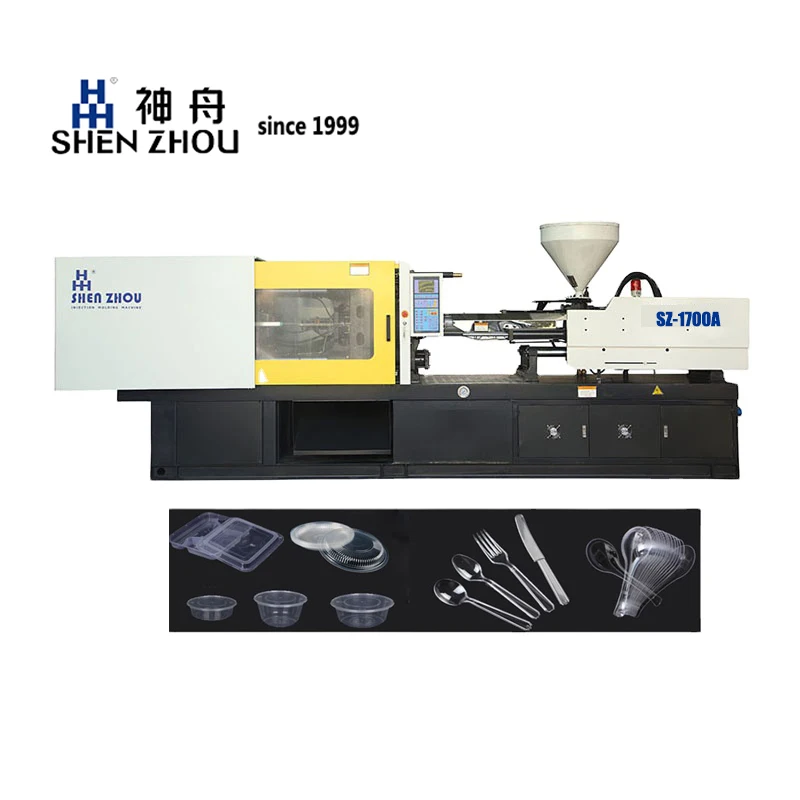

Sample Display