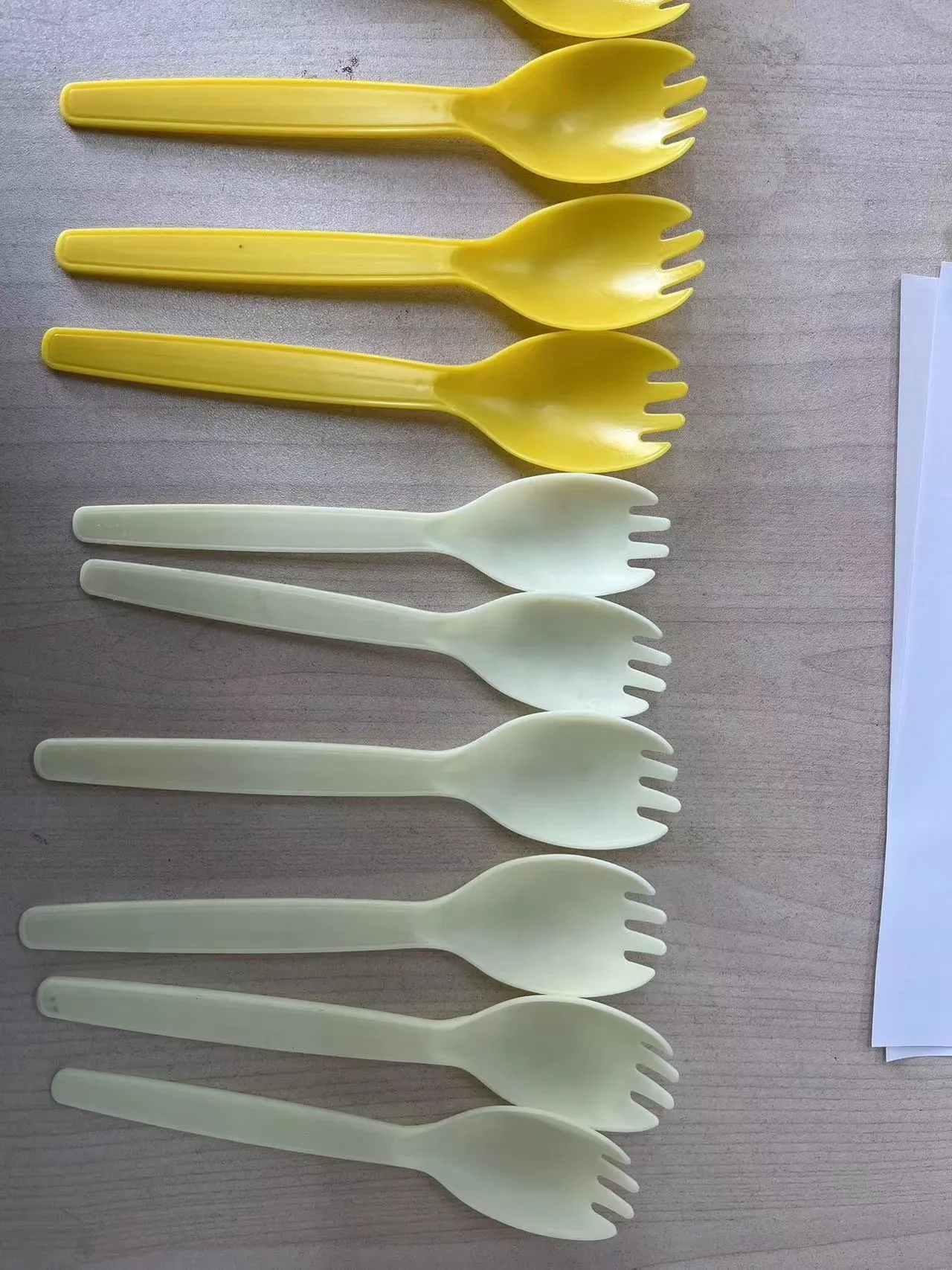

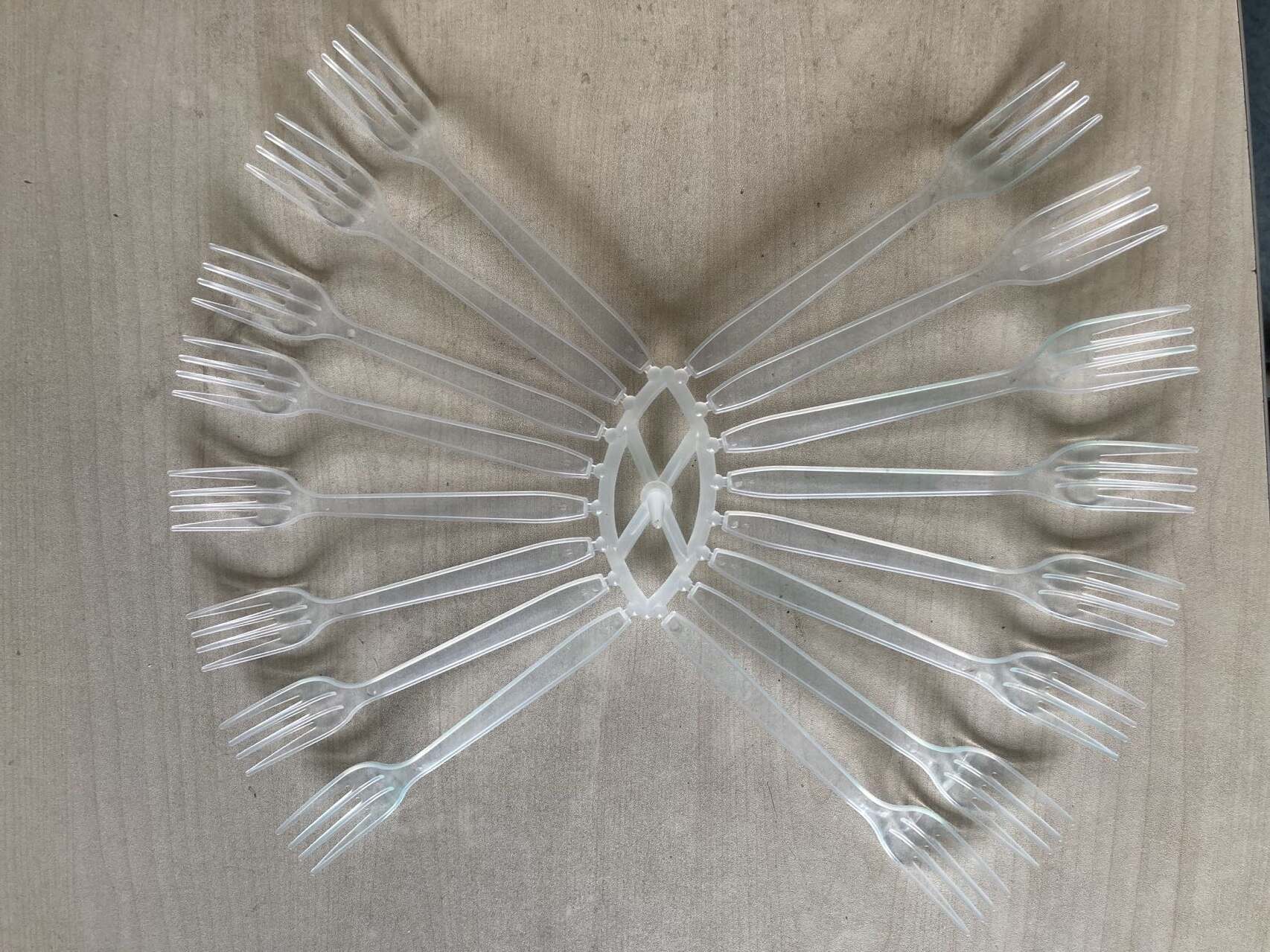

Plastic Fork&Spoon&Knife Injection Mold

A high-quality plastic knife, fork and spoon mold should take into account four core conditions: high production capacity, high qualification rate, long service life and compliance with food-grade standards.

Description

Plastic knives, forks, and spoons are a common type of tableware made from plastic materials through injection molding technology. This article will provide a professional introduction to plastic knives, forks, and spoons from two aspects: their benefits and injection molding process.

Firstly, plastic knives, forks, and spoons have various benefits. Firstly, plastic knives, forks, and spoons are lighter in weight compared to traditional metal tableware, making them more convenient and comfortable to use. Secondly, plastic knives, forks, and spoons have good wear resistance and corrosion resistance, are not prone to rust and discoloration, and have a longer service life. In addition, plastic knives, forks, and spoons also have good insulation performance and are not easy to conduct heat, which can effectively avoid the risk of burns. In addition, plastic knives, forks, and spoons can be made into various shapes and colors through injection molding technology to meet the personalized needs of different consumers.

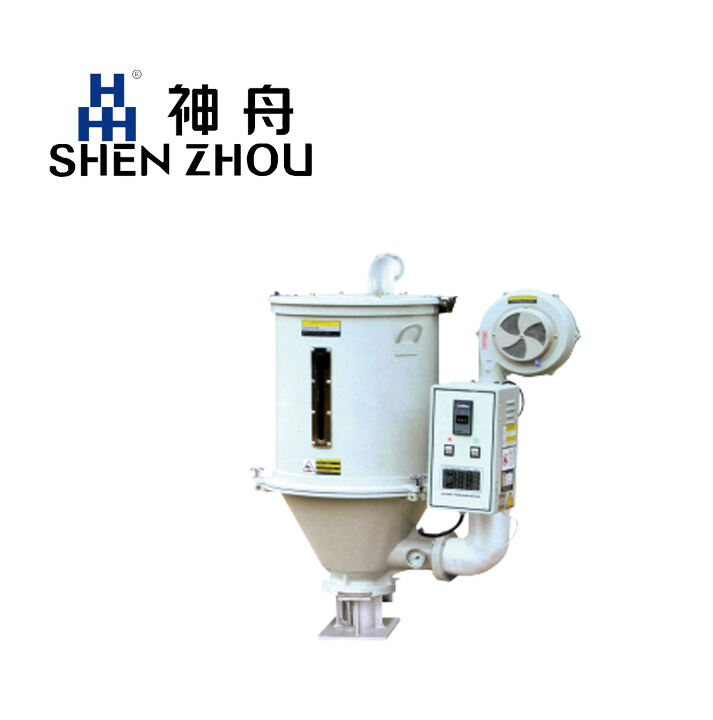

Secondly, the manufacturing process of plastic knives, forks, and spoons mainly adopts injection molding technology. Injection molding process is a processing method that injects molten plastic into a mold through an injection machine, cools and solidifies it to obtain the desired product. Specifically, the injection molding process includes steps such as raw material processing, injection molding, cooling and solidification, and demolding. Firstly, it is necessary to process the plastic raw materials, including drying, mixing, and dyeing. Then, place the processed plastic particles into the hopper of the injection machine, and heat and melt them to turn them into a molten state. Next, inject the molten plastic into the mold and solidify it during the cooling process. The cooling system plays a role in reducing the temperature of the mold to ensure the quality and dimensional stability of the product. After the plastic knife, fork, and spoon are cured, the mold opens and closes, and the finished product is taken out.

In summary, plastic knives, forks, and spoons, as a common type of tableware, have the advantages of being lightweight, wear-resistant, corrosion-resistant, and insulated. Its manufacturing process adopts injection molding technology, by injecting melted plastic into the mold, cooling and curing to obtain the required product. The injection molding process has the characteristics of high efficiency and flexibility, which can meet the production needs of plastic knives, forks, and spoons of different shapes and colors. With the continuous progress of technology, injection molding technology will further develop and improve, providing more possibilities for the production of plastic tableware.

Disposable plastic pvc, pp ice cream spoon, plastic knife and fork, strong toughness, not easy to break.