Injection molding systems are machines that do a lot of things. They’re employed in a wide variety of industries for a wide variety of stuff, from toys to containers to parts in cars and machines. Machines like these are "very critical, so we can get things done fast and right," he says. Lets take a closer look into how these Injection Molding Systems function and how you can benefit from the same.

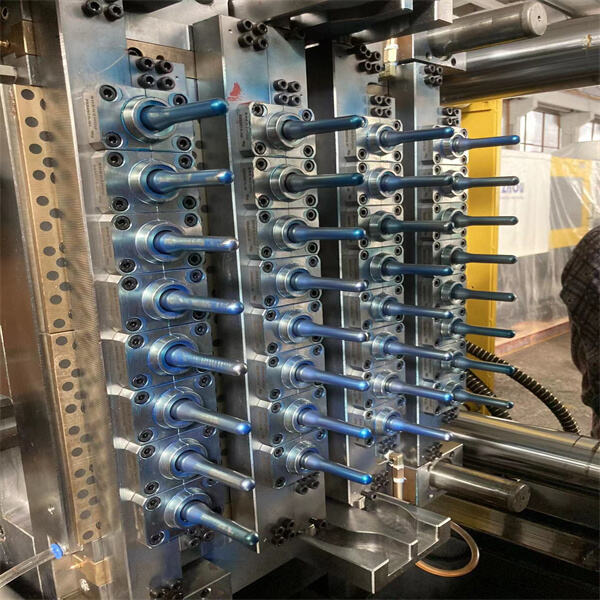

Injection molding is a special process for creating things from plastic. It’s sort of like baking a cake. So, you feed the ingredients, plastic pellets, into the machine’s “oven” (barrel). Then the pet injection machine by SHENZHOU blends the ingredients and heats them to a melted state. Then the machine squirts the melted plastic into a mold — think filling a cake pan with batter. Finally, the machine cools the plastic, which hardens into the shape of the mold. Voila! You have a shiny new plastic thing?