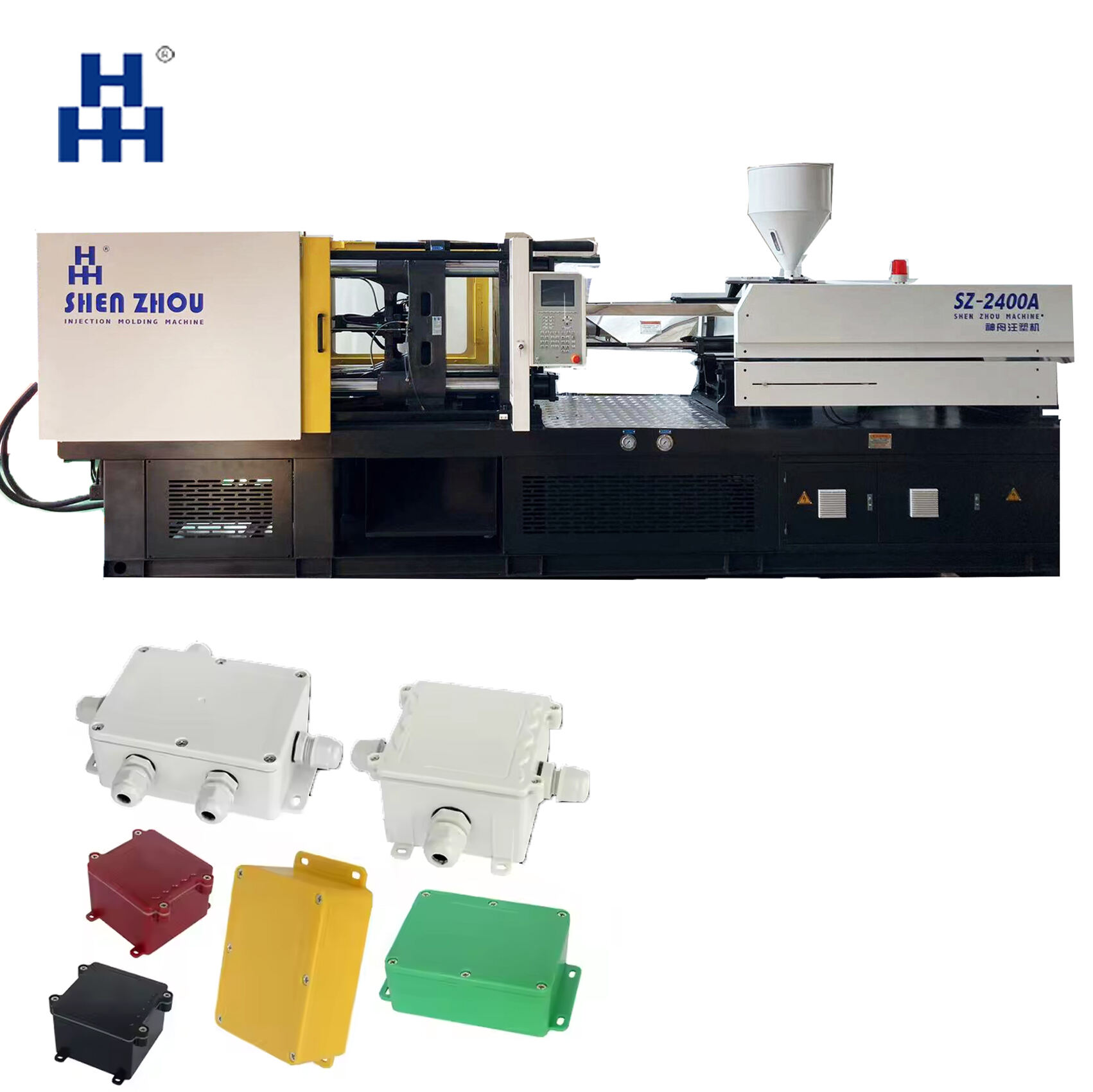

With the aid of pet injection moulding machine manufacturers product making process becomes simpler. These gadgets operate by melting plastic and depositing it into a mold that gives it a specific shape. In this post, we are going to discuss the following points: what pet equipment is, benefits of using an pet injection molding machine, how they are shaping pet products, how the machine operates, as well as how to choose the right one for your business

Pet injection moulding machines are special machines used to produce pet products like food and water bowls and pet toys. Plastic pellets are heated until they melt and then are injected into a mold. Once the plastic has cooled, the mold can be removed and the plastic can be used. These plastic bottle preform machine can produce a great variety of shapes and sizes.