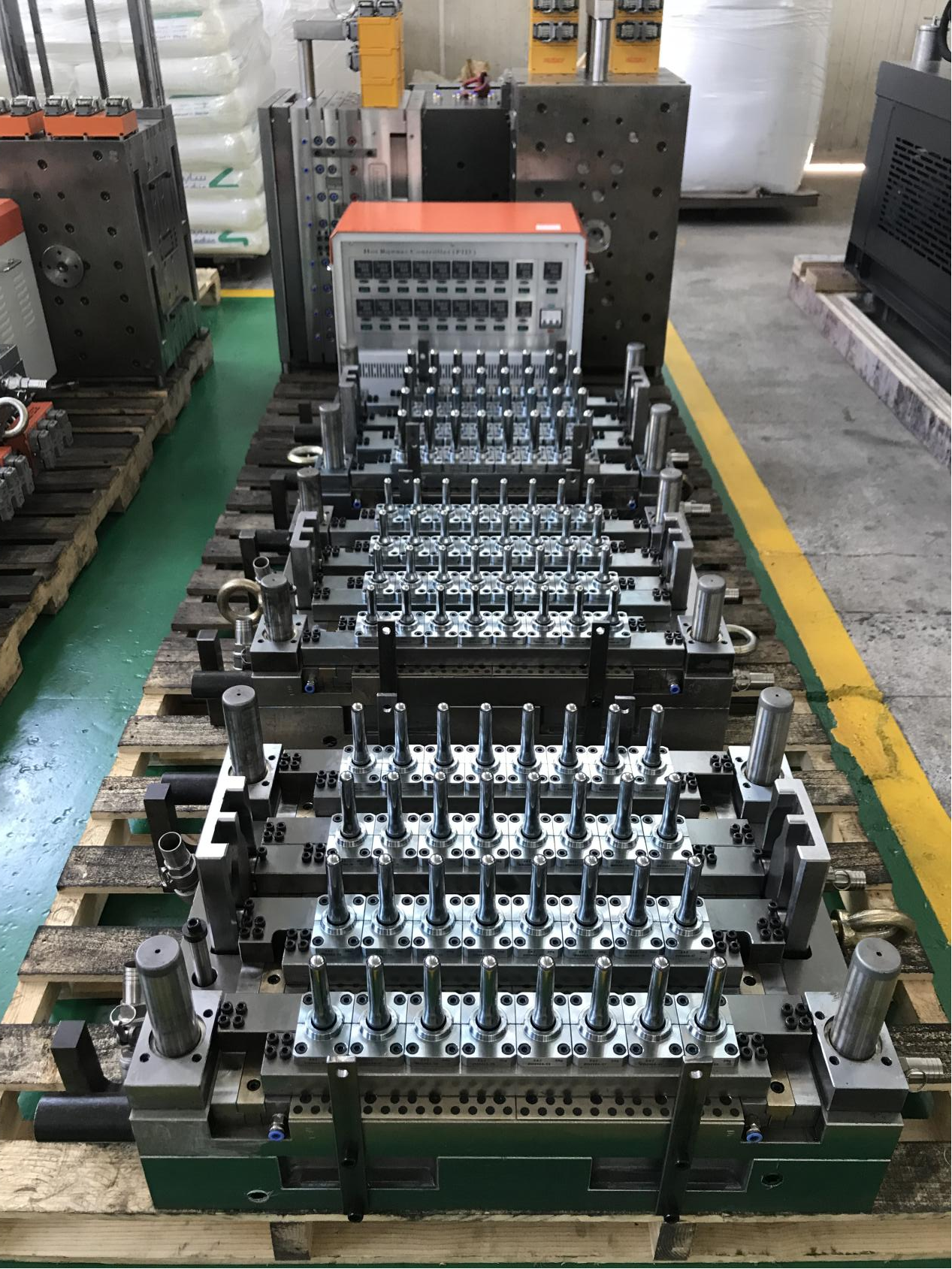

Injection mold is an forming tool used to mass production of products from some material such as plastic. These molds can be in any size or shape, and come with their own price tag. The price of injection molds can be influenced by a number of factors, the details can be different.

The price of the injection mold, is inseparable from the type, quality of the material. Better quality materials like steel or aluminum may make the mold stronger and last longer but can add cost. Cheap materials wont last and can be more difficult to work with, or your parts will just look like you used cheap filament.

Advantages

Cost of manufacturing increases with design complexity of an injection mold. Simple molds are faster and simpler to produce and are therefore less expensive. Clothing with detailed or multiple components can take longer and require more skill to mold, though, leading to higher costs.

The number of parts to be produced by the mould also influences the cost as large volume parts may require premium materials and more precision. For molds that produce a a lot of parts, continuous operation without wearing out is important. This can result in them needing to be constructed from more costly materials or add other attributes just to ensure accurate repeat measurements for the duration of a workpiece design or even the lifetime design for some items.

Benefits

Urgency as well as timing requirements can effect the cost of a mold since rush charges are usually added. Manufacturers who can’t keep up with tight deadlines may also need to pull longer hours or change their schedules, generating higher prices for the molds they’re making. Advance planning, plus a generous lead time for production can help to keep prices in check.

Features

The expertise and experience of the mould manufacturer may also impact on its price, with better and experienced manufacturers costing more. A more established manufacturer with a long history of successfully producing quality molds may charge consumers steep prices for his or her service. This higher initial price for the mold often pays off, however, as a higher end product is delivered as anticipated or in a much higher quality since it was designed more effectively and developed more robustly.

Summary

In addition, there are some elements will affect the cost of injection molds. The options of materials and their grades, the intricacy of the design, the volume of parts you need and how soon you need them, as well as the capabilities of the manufacturer (that is, how good they are at doing their job, and how easy they are to work with) all affect the final price. Knowing these details will not only help manufacturers decide what molds they must have but also budget for them. At SHENZHOU, we recognize the importance of both quality and cost effectiveness in injection moulds, and ensure we are priced competitively in all our markets.