To produce perfect parts in injection molding, the process requires expertise and especially excellent precision in the mold. Problems such as warping, sink marks, short shots or flash can result in having to scrap parts, delays and costing more. Shenzhou Machinery knows that preventing problems begins with the mold.

Our approach to minimizing defects focuses on:

Precision Design and Engineering: Using modern design tools and detailed understanding of materials, our team can expect possible problems. We design the points for gates, the cooling system and the ejection methods before we start machining anything. Doing design optimization ahead ensures there are no flow imbalances, uneven cooling (which often results in warping and sink marks) and difficulties with ejection.

High-Accuracy Manufacturing: Using modern CNC machining centers, EDM and grinding tools, we make molds with very precise measurements. The detailed nature of this machining gets rid of flash arising from gaps in the mold parts and ensures vents are open for effective gas venting and no gas traps. The part will be consistent only if the mold cavity is perfectly dimensional.

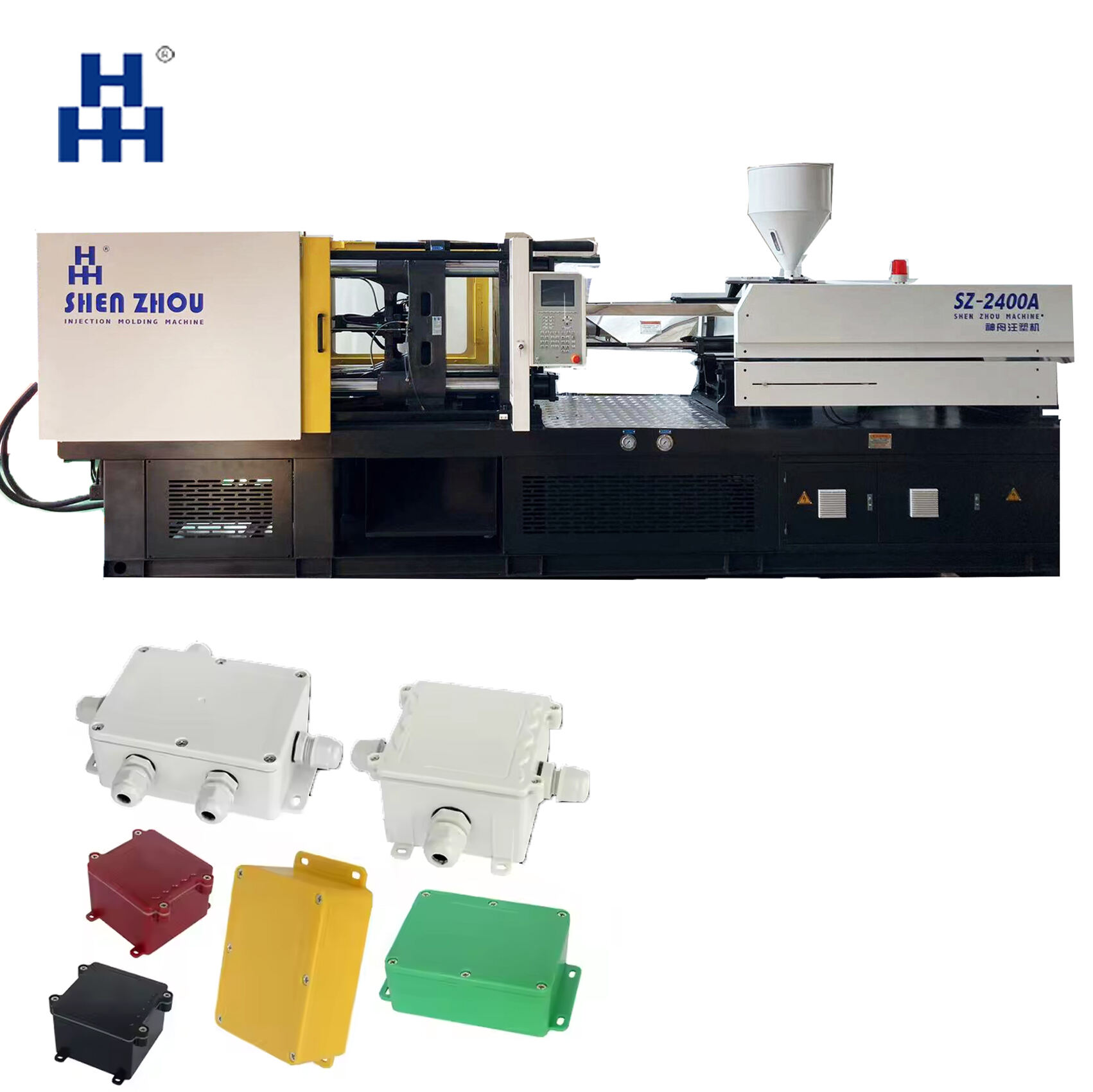

Rigorous Prototyping and Testing: To spot potential issues before moving on to full-scale production, we use trial molding (often done ourselves with our machines) during the testing phase. We look at the first parts, adjust the settings for processing and make any improvements to the mold. At this step, any little issues with details or condition are likely to be found and put right.

Strict Quality Control: Strict checks are performed from selecting the raw materials to the final inspection in the whole process of mold making at Shenzhou Machinery. As a result, every mold part works as expected and the mold is dependable in making parts without flaws from inside the mold or due to wear.

Partner with Shenzhou for Defect-Reduced Molding

Using detailed mold design, high-precision procedures, multiple checks and total dedication to quality, Shenzhou Machinery assures that its injection molds support the manufacture of quality plastic goods. Quality engineering ensures every mold is dependable for less waste and improved manufacturing processes.

Contact Shenzhou Machinery today to discuss how our expertise can help you achieve flawless injection molded parts.