Injection mold components are the key parts of production regarding various products. It is very important that these four components and other key components work properly in order to maintain an effective and efficient process of producing items like toys, tools, and containers.” In this article, we will discuss essential aspects of an injection mold component together understanding why they are essential to the industry.

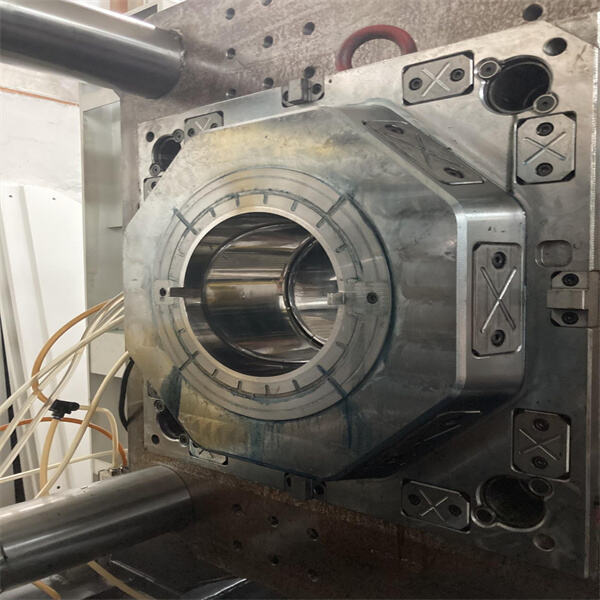

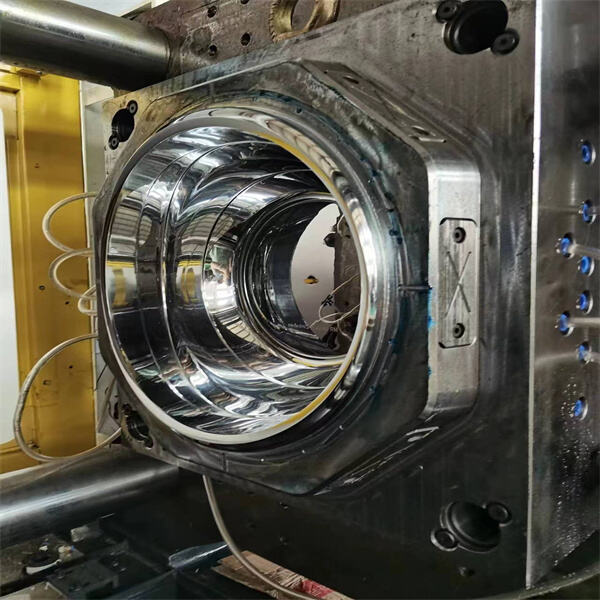

Injection Mold Components Injection mold components are the tools used to mold and shape products by the process of injection molding. These consist of the mold base, cavity, core, cooling system and ejector pins. The mold base is the starting point for building a mold, and it includes the mold plates, and clamping plate, to which the mold is attached. The cavity and core are the two parts of the mold that form the actual product shape. Ejector Pins eject the part from the mould after it has been created. The cooling system is used to adjust the temperature of the mold in the process of injection molding.