PVC injection molding machines are good tools to make anything made of plastic. Can these machines be large and even appear complicated? Yes, but they function in a simple way. In this guide, you’ll learn everything about PVC Injection Molding Machine, why they are indispensable, how to choose the best but above all, how to take care of the machines.

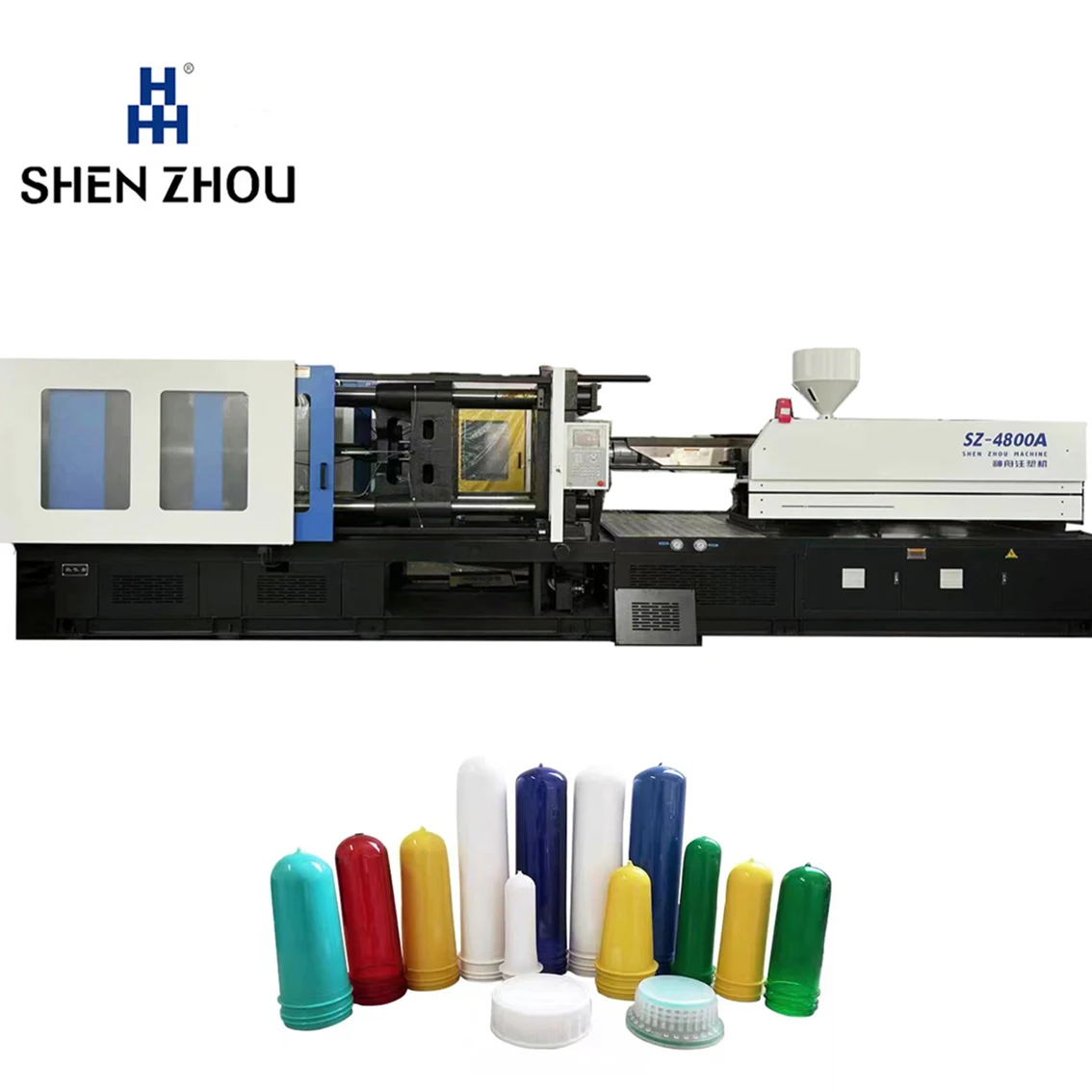

What is a PVC Injection Molding Machine? We recommend PVC (vinyl) as it is strong yet also flexible, allowing for easier use. The machine has a big metal barrel in which small pieces of PVC called pellets are melted. Once melted, the hot liquid PVC is injected into a mold to form a product. After the PVC cools and hardens, the mold opens and the product pops out.