In simple terms, when the wall thickness is less than 1mm, it is called thin-wall. More generally, the definition of thin-wall is related to the flow/wall thickness ratio, the viscosity of the plastic and the heat transfer coefficient.The process flow L from the main flow of the thin-wall injection mold to the farthest point of the finished product, divided by the wall thickness t of the finished product, is called the process/wall thickness ratio. When L/t>150, it is called thin wall. What are the main materials used in thin-wall injection mould?The melt index (MI) of PP plastic is as high as 60(g/10min), such as Basell's Moplen RP1086. many finished products are made of PS/ABS because of the toughness of PC and the fluidity of ABS, which are also suitable for thin-wall injection mould. What are the main applications of thin-wall injection mould?The molding process of plastic packaging boxes using thin-wall injection mould mainly includes injection molding, extrusion molding, blow molding, etc. Among them, injection molding is the most commonly used molding process for plastic packaging boxes because of its simple process, easy operation and reproducibility of molded products.Injection molding, also known as injection molding or injection molding. It is an important polymer material molding processing method. Injection molding products are widely used, and its total amount accounts for about 80% of engineering plastic products and 30% of total plastic products. What are the technical characteristics of thin-wall injection mould?Thin wall injection molding technology is also known as thin wall injection molding technology. The definition of thin wall is related to the process/wall thickness ratio, the viscosity of the plastic and the heat transfer coefficient. There are three main definitions of this technology:

1. the ratio of flow length to thickness L/T, i.e. the ratio of the flow length L from the point where the melt enters the mold to the farthest point of the cavity where the melt must be filled to the corresponding average wall thickness T is 100 or 150 or more for thin wall injection molding;

2. the injection molding method in which the thickness of the molded part is less than 1 mm and the projected area of the molded part is more than 50 c㎡;

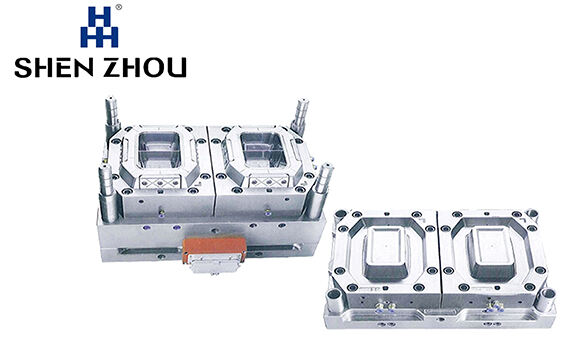

3. the wall thickness of the molded part is less than 1 mm (or 1.5 mm), or the t/d (thickness of the part t, diameter of the part d, for disc-type molded parts) is less than 0.05 is defined as thin-wall injection mould.It can be seen that the critical value of the definition of thin-wall injection mould will also change, and it should be a relative concept. ZHANG JIA GANG SHEN ZHOU MACHINERY CO.,LTD. are an entity factory with a whole line of injection molding machines. We gather many years of rich experience to make “SZ” series automatic computer Injection Molding Machine and its equipment. Its excellent quality, stable performance, attractive price-performance meet the client's demands and profits.