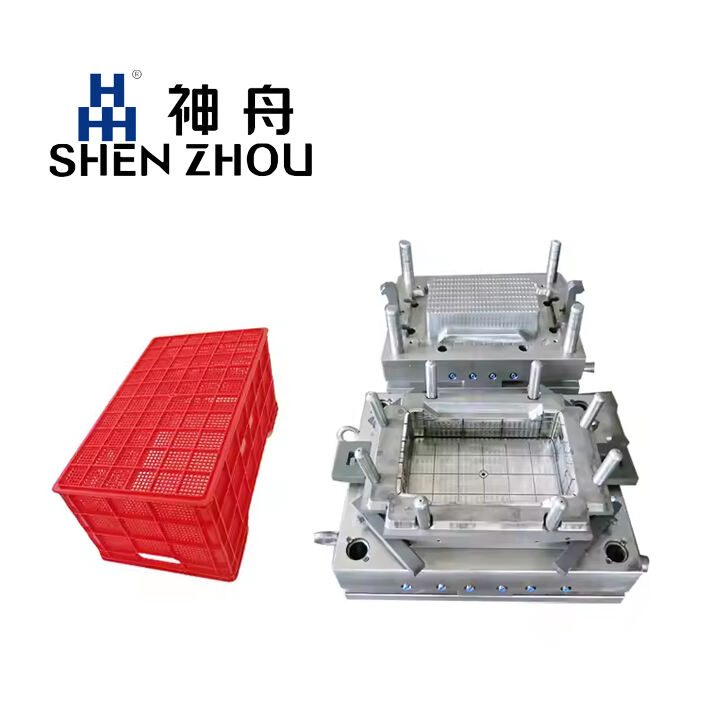

Description

Good molds have significant advantages in design, manufacturing, application and output effect, which can directly enhance production efficiency, reduce costs and ensure the stability of product quality.

1. High precision and high stability: Ensure product consistency

Excellent dimensional accuracy

The machining accuracy of the mold cavity/core can reach ±0.005 to ±0.01mm , ensuring that the dimensional error of mass-produced products is ≤±0.05mm, meeting the strict assembly requirements .

Excellent surface quality

The surface of the cavity is treated with mirror polishing or coating, which makes the surface gloss of the product reach over 90°, and there are no defects such as scratches and weld marks, reducing the post-processing procedures.

Strong long-term stability

Made of high-strength die steel and treated with vacuum quenching, the hardness uniformity is ≤±2HRC, and the dimensional change within the die's service life is less than 0.03%, ensuring that the product quality remains unchanged after continuous production of hundreds of thousands of dies.

2. efficient production: Shorten the cycle and reduce costs

Rapid prototyping and demolding

The optimized flow channel design shortens the mold filling time by more than 30%. Combined with the efficient cooling water channel, the molding cycle can be reduced by 20% to 50%

Low energy consumption and easy maintenance

The designs such as self-lubricating guide pins and pneumatic demolding reduce the energy consumption of the equipment. Vulnerable parts. It adopts a modular design, with a replacement time of less than 15 minutes, reducing downtime losses.

High material utilization rate

Hot runner molds have almost no runner waste. Combined with the precise injection molding process, the material loss rate can be controlled within 1%, reducing raw material costs.

3. Long service life and high reliability: Outstanding durability

It has strong resistance to wear and corrosion

The structural strength is reliable.

Adapt to complex processes