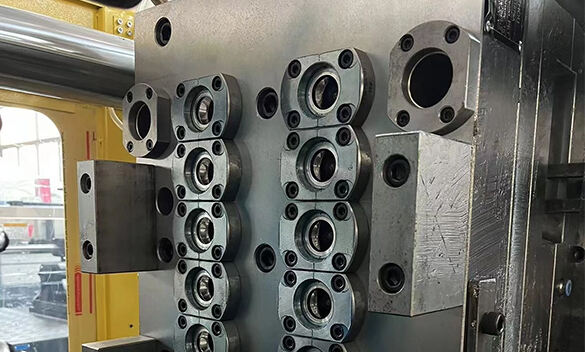

Trial steps and actionsA. Before trial molding, check whether the mold has been assembled and whether the raw materials have been driedB. Before changing the mold, spray rust inhibitor on the mold during production, replace the mold and return it to its original position, and fill out a record formC. When installing the mold, it should be aligned with the center point of the mold before carrying out the mold mounting work. The mold must be locked tightly and the effectiveness of the high-pressure locking mold must be checked. The locking force depends on the size of the mold, and a high pressure of 80-90 PMa is required for a large mold; High pressure of 40-65 PMa required for small molds; After adjusting the lock mode high pressure, the switch mode is adjusted to the normal speed, and the low pressure time, distance, pressure, and speed are adjusted. Low pressure work is important during normal production, and the reason for mold damage is due to incomplete low pressure workD. To clear the material pipe, other colored raw materials and impurities inside the pipe should be removed, and the injection pressure, holding pressure, injection time, and holding pressure should be reduced to 50PMa; Adjust to the required pressure according to the product condition, and compare the low-pressure forming condition sample, medium pressure forming condition sample, and high-pressure forming condition sample to analyze the flow channel methodE. Before trial molding, manually test the mold to confirm whether the demolding action is smooth and the return condition is good. When the trial molding is launched, spray the demolding agent to the mother mold condition first, and then adjust the demolding position after formingF. The quantity of each trial mold is based on the production management notice, and the mold department must be notified to confirm the trial mold action together before each trial operation; After testing the product, go to the customer for review After the review is completed, fill out the forming condition record form and mold condition formG. When the trial mold is completed, the mold is first sprayed with rust inhibitor, and then the mold is lowered to the mold department for modification work,H. Each trial mold must follow the above items before trial molding, with accurate trial molding time and personnel dispatched by superiors. Do not trial mold without permission