one Causes of flash formation:

1-1 The mating surfaces of the mold parting line (PL) and the sliding surface do not fit properly.

1-2 The injection pressure is too high.

1-3 The injection machine is misaligned.

1-4 The clamping force is insufficient.

Othercauses

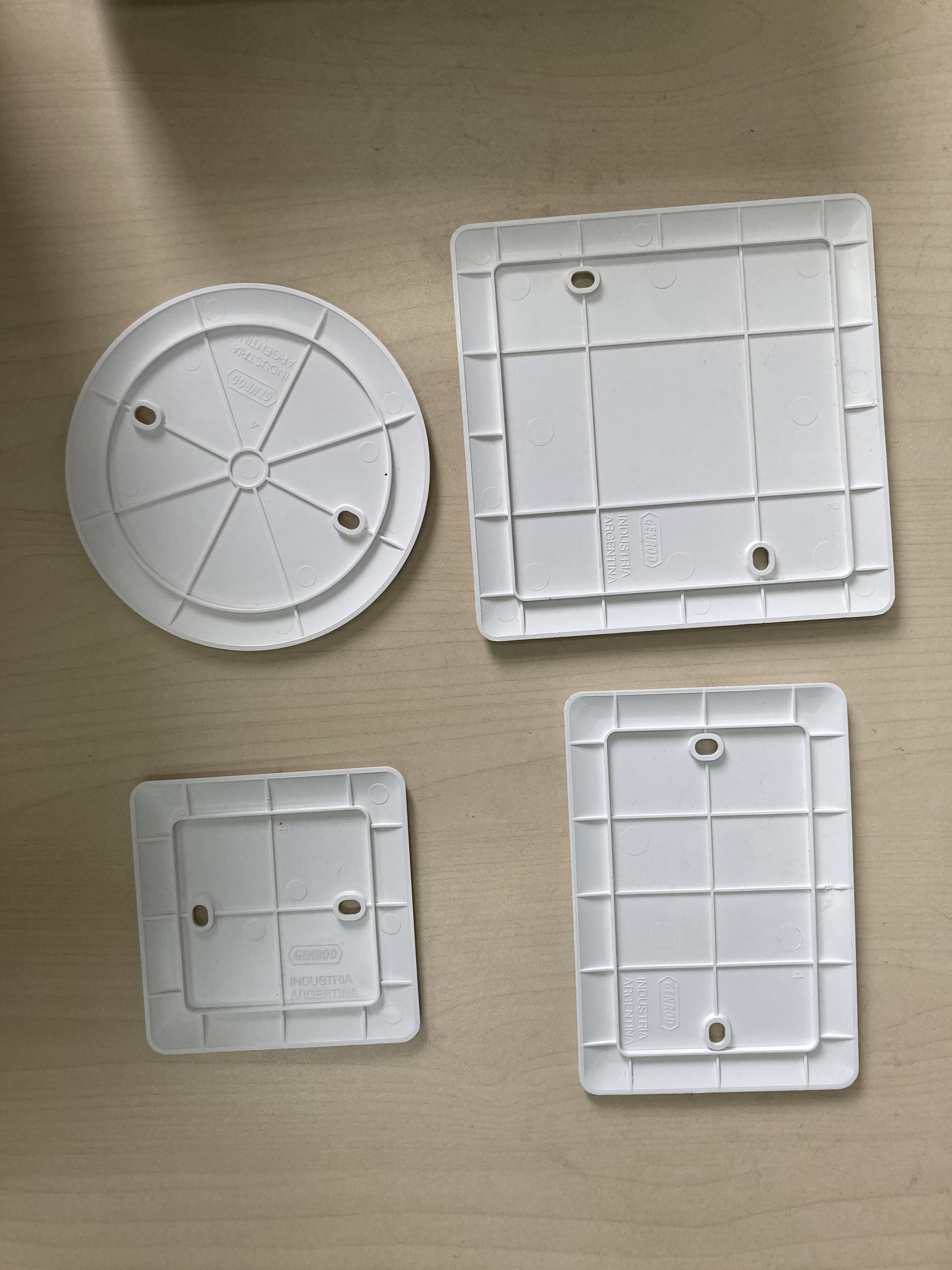

2-1 The parting surface PL of the mold, the sliding mating surface, the demolding pin, the spacer, etc. form the gaps between various grooves of the mold. If the material flows in, it will become flash. The flash is in the shape of a wedge and tends to gradually increase in size.

2-2 To eliminate the flash on the product, it is generally based on repairing the mold. For the flash that occurs temporarily due to improper setting of the molding conditions, the parameters should be set in the direction of reducing the barrel temperature, lowering the mold temperature, and decreasing the injection speed to reduce the material's fluidity. However, it should be noted that this may cause residual internal stress in the product.

Solutions

3-1 Immediate: Reduce the injection pressure, lower the barrel temperature, and decrease the injection speed.

3-2 Short-term: Grind the surface of the mold where the flash occurs.

3-3 Long-term: Use hard steel material for the mold.