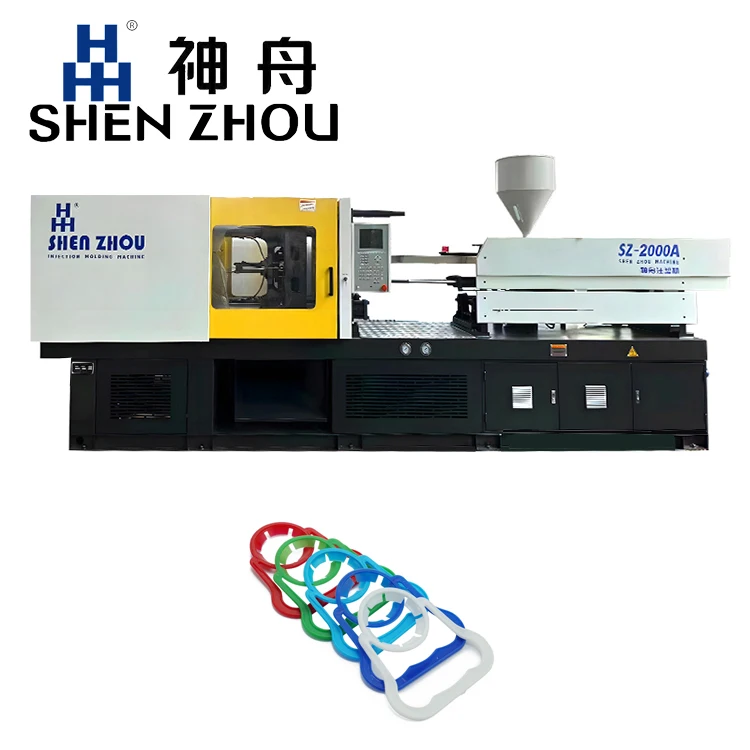

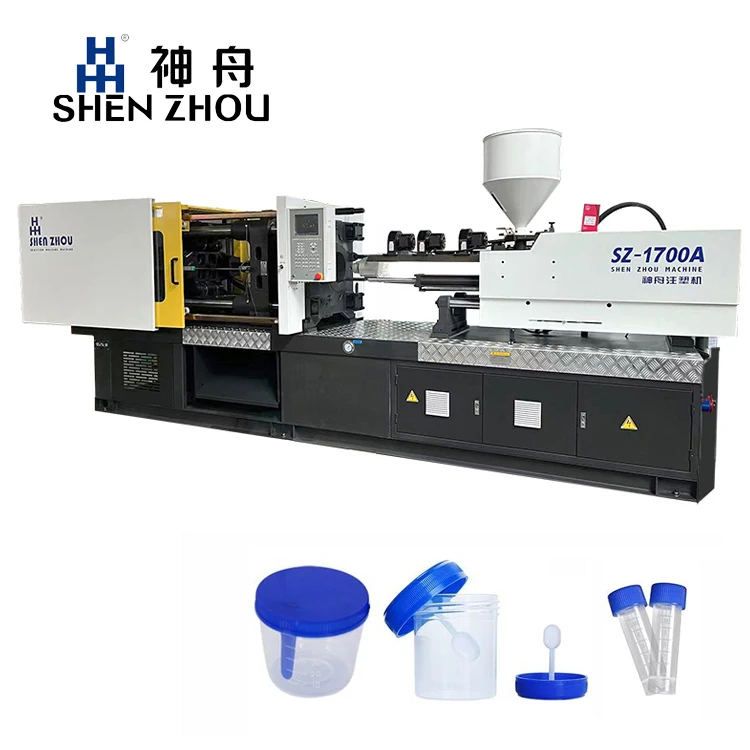

Plastic Bottles Handles Injection Molding Machine

The plastic bucket handle is a core load-bearing component of the water bucket. It is a small, high-toughness, and high-precision injection molded part. The core production requirements are that it meets the toughness standard without cracking, does not deform under load, has a precise size fit for the bucket body, and has no appearance defects. At the same time, it is suitable for large-scale mass production needs

Description

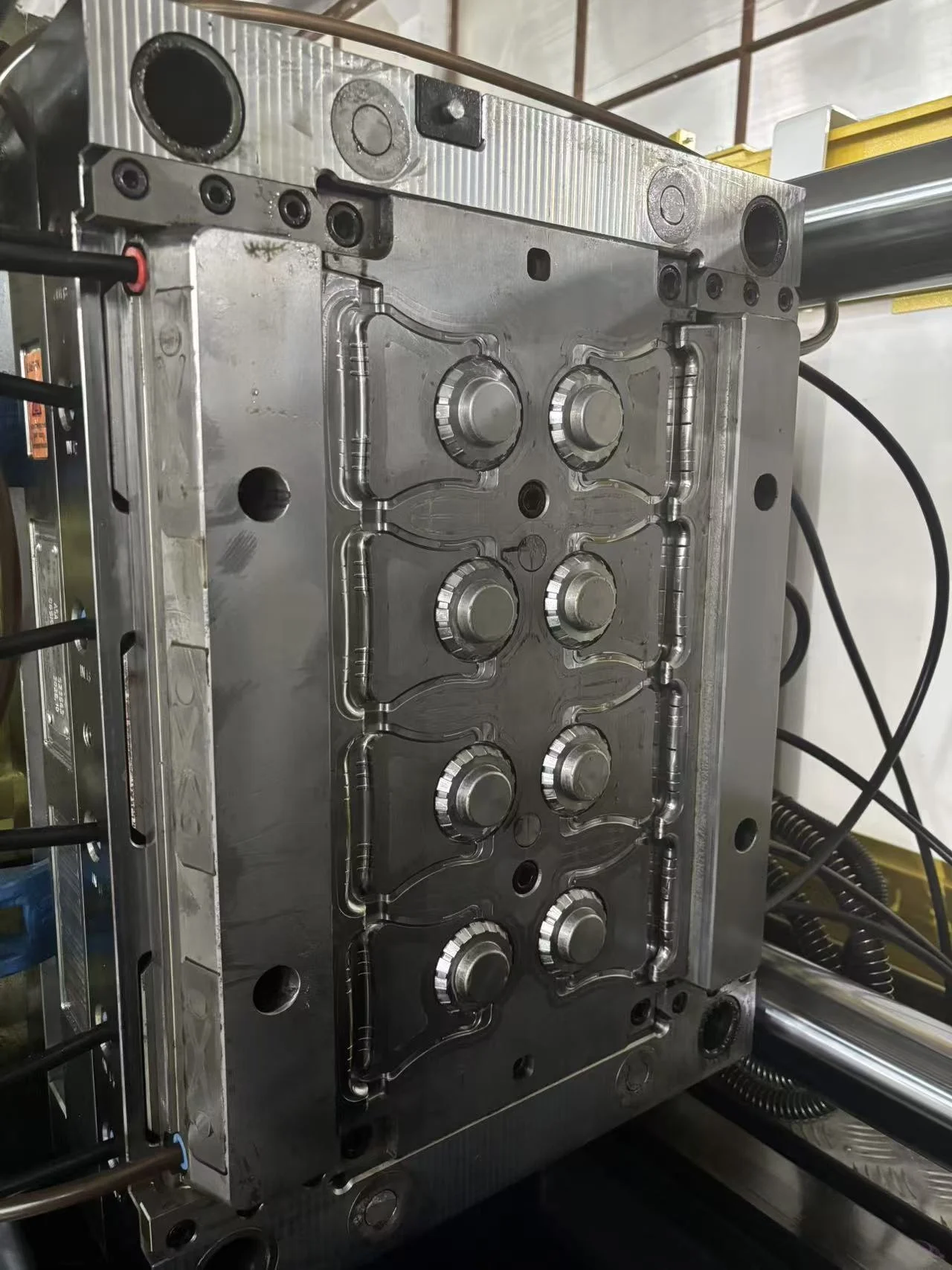

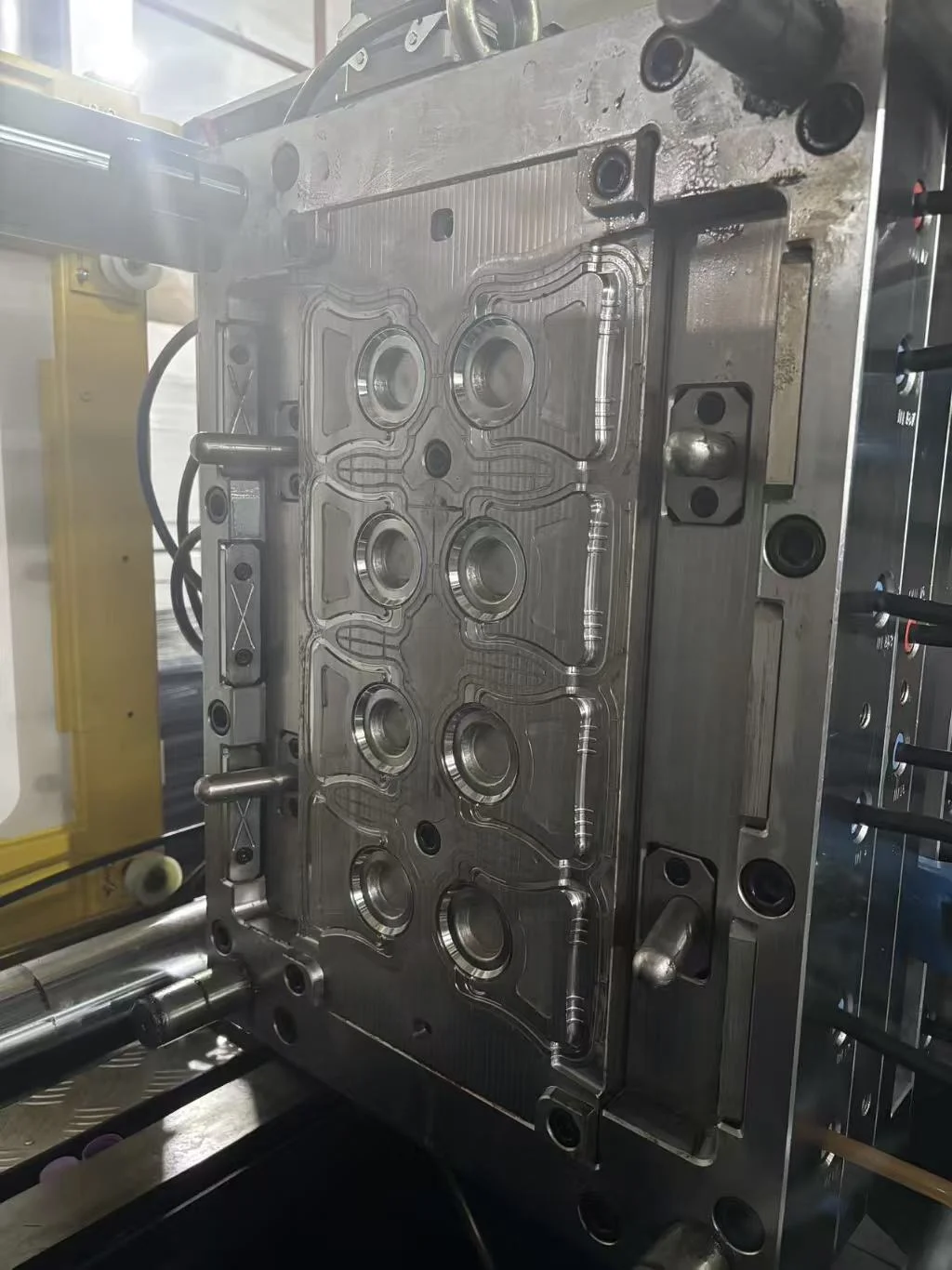

Exclusive requirements for bucket handle molds

The handle mold is the key to mass production. Multi-cavity design, high-toughness cavity, and smooth demolding are the core. All requirements revolve around "high capacity, zero defective products, and long service life", and none of them can be missing.

Cavity design: Prioritize multiple cavities to adapt to different models.

Cavity design: Prioritize multiple cavities to adapt to different models.

The small handle parts are suitable for multi-cavity mass production and are the core for cost reduction: the 80t model is compatible with 16-24 cavities, the 120-160t model is compatible with 32-48 cavities, and the 200t model can achieve 64 cavities. The number of cavities is not necessarily the more the better. It is necessary to ensure that the molten material is evenly distributed in each cavity to avoid material shortage and shrinkage in some cavities.

Mold material and polishing: balancing durability and appearance

The cavity/core is made of 718H pre-hardened steel (cost-performance ratio) /S136 stainless steel (food grade), with a hardness of HRC48-52, which is wear-resistant and impact-resistant. The mold life is ≥3 million cycles, and it will not wear out during long-term mass production.

The cavity surface is polished to Ra0.4-0.8μm, smooth without dead corners, to prevent scratches and mold sticking on the handle surface. The food-grade bucket handle needs to be mirror-polished with S136, in compliance with GB4806/FDA standards, and no harmful substances are released.

Structural design: 3 key details to eliminate production difficulties

1.Gate: Prioritize the selection of point gates or latent gates, located at the root of the handle (non-load-bearing/contact area). The gate marks are small, no secondary pruning is required, and it does not affect the appearance or load-bearing capacity. It is prohibited to open the gate at the force-bearing part of the handle to avoid stress concentration and brittle cracking.

2.Demolding: A combination of ejector pins and spring pins is used for demolding. The ejector pins are evenly distributed on the inner side of the handle, providing consistent force to prevent ejection damage and deformation during demolding. The mold comes with a demolding slope of 1-2°, ensuring smoother demolding and can be directly connected to a mechanical hand for automatic part removal.

3.Cooling: The water channels of the mold are close to the cavity, ensuring independent cooling for each cavity. The water channels are unobstructed without dead corners, and the mold temperature is uniform and stable. This shortens the molding cycle and prevents the handle from warping or deforming due to uneven cooling.

Mold material and polishing: balancing durability and appearance

The cavity/core is made of 718H pre-hardened steel (cost-performance ratio) /S136 stainless steel (food grade), with a hardness of HRC48-52, which is wear-resistant and impact-resistant. The mold life is ≥3 million cycles, and it will not wear out during long-term mass production.

The cavity surface is polished to Ra0.4-0.8μm, smooth without dead corners, to prevent scratches and mold sticking on the handle surface. The food-grade bucket handle needs to be mirror-polished with S136, in compliance with GB4806/FDA standards, and no harmful substances are released.

Structural design: 3 key details to eliminate production difficulties

1.Gate: Prioritize the selection of point gates or latent gates, located at the root of the handle (non-load-bearing/contact area). The gate marks are small, no secondary pruning is required, and it does not affect the appearance or load-bearing capacity. It is prohibited to open the gate at the force-bearing part of the handle to avoid stress concentration and brittle cracking.

2.Demolding: A combination of ejector pins and spring pins is used for demolding. The ejector pins are evenly distributed on the inner side of the handle, providing consistent force to prevent ejection damage and deformation during demolding. The mold comes with a demolding slope of 1-2°, ensuring smoother demolding and can be directly connected to a mechanical hand for automatic part removal.

3.Cooling: The water channels of the mold are close to the cavity, ensuring independent cooling for each cavity. The water channels are unobstructed without dead corners, and the mold temperature is uniform and stable. This shortens the molding cycle and prevents the handle from warping or deforming due to uneven cooling.

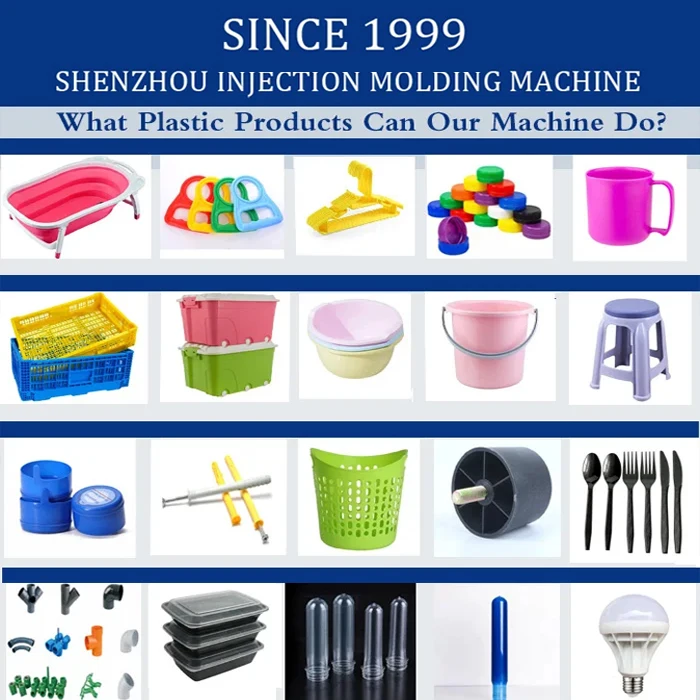

Products Description

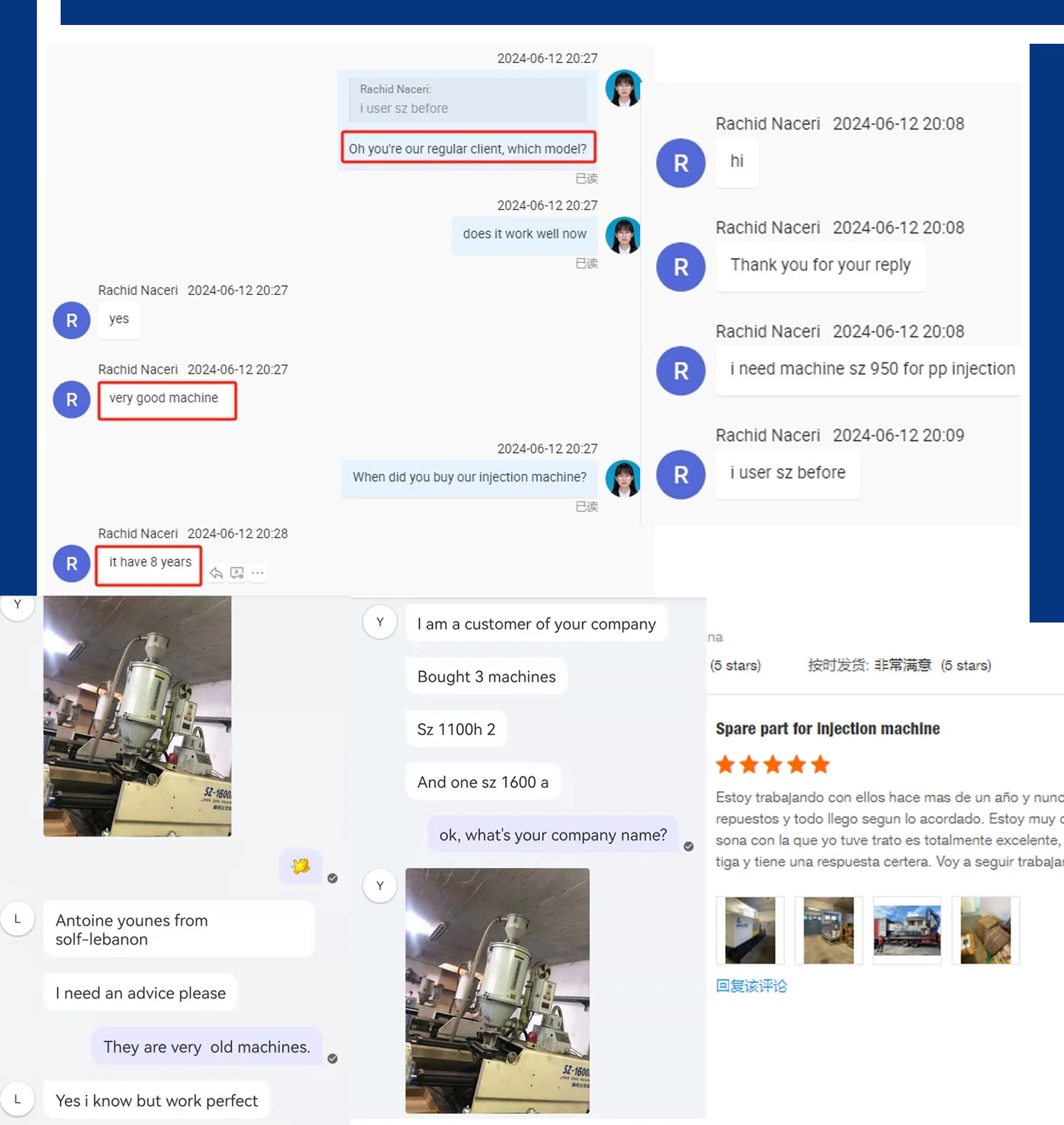

reviews

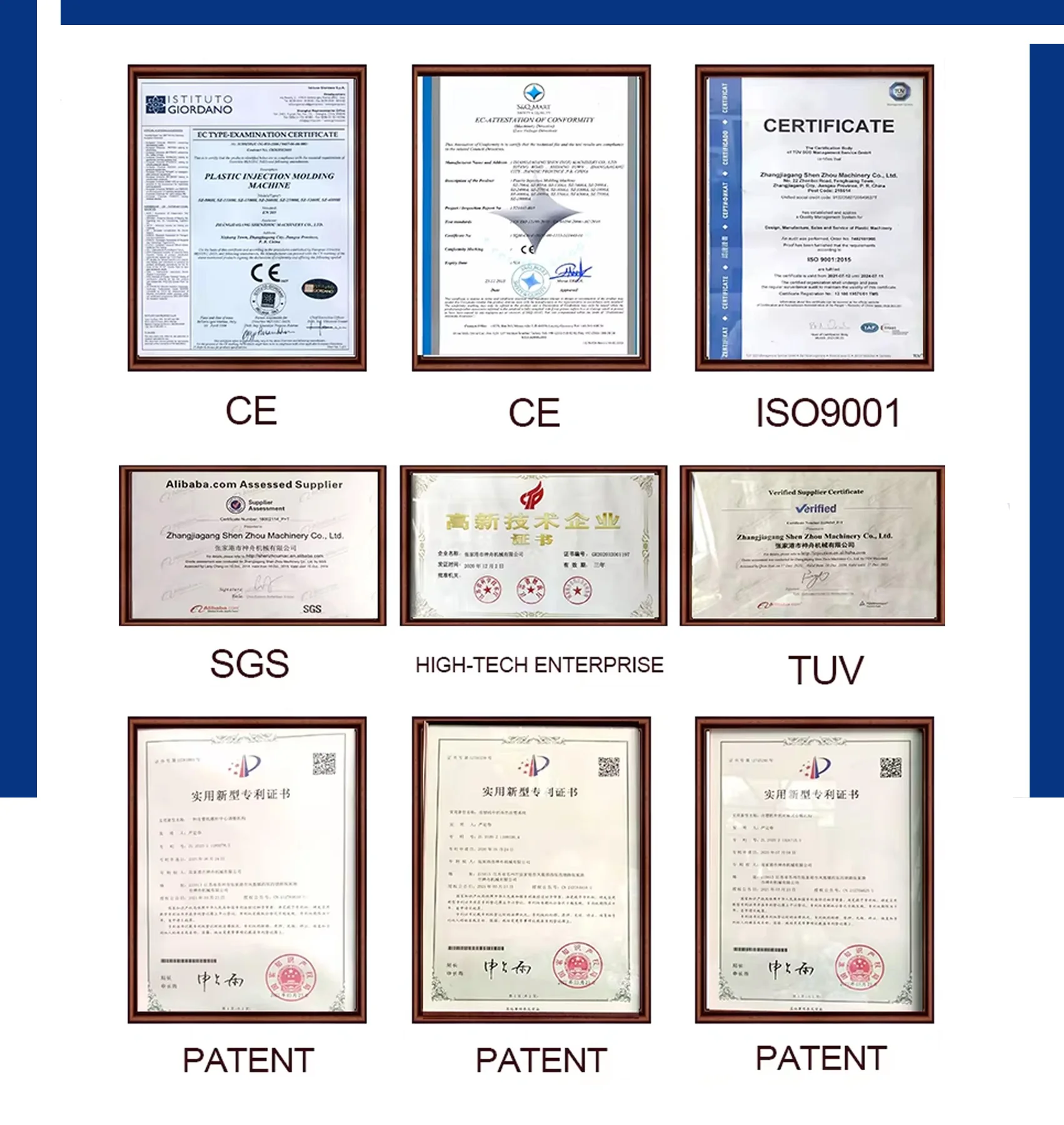

Certifications

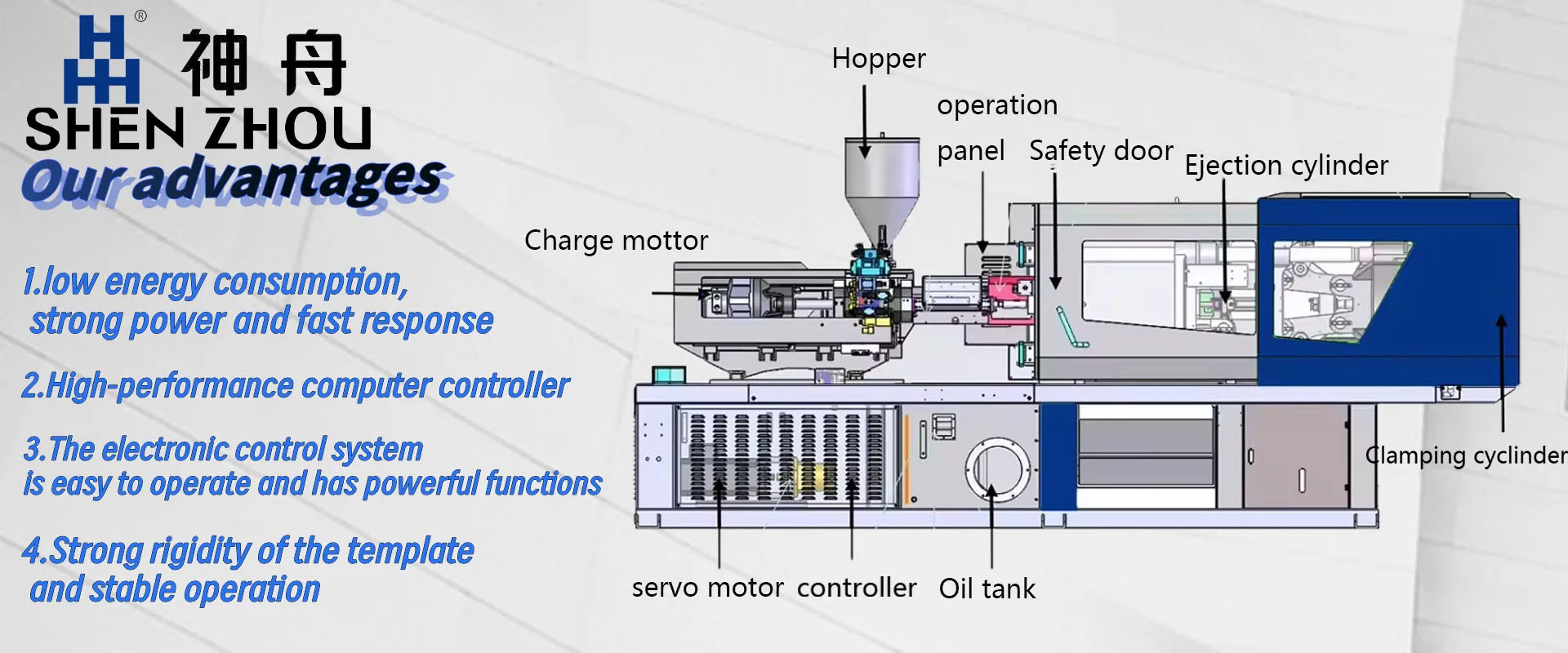

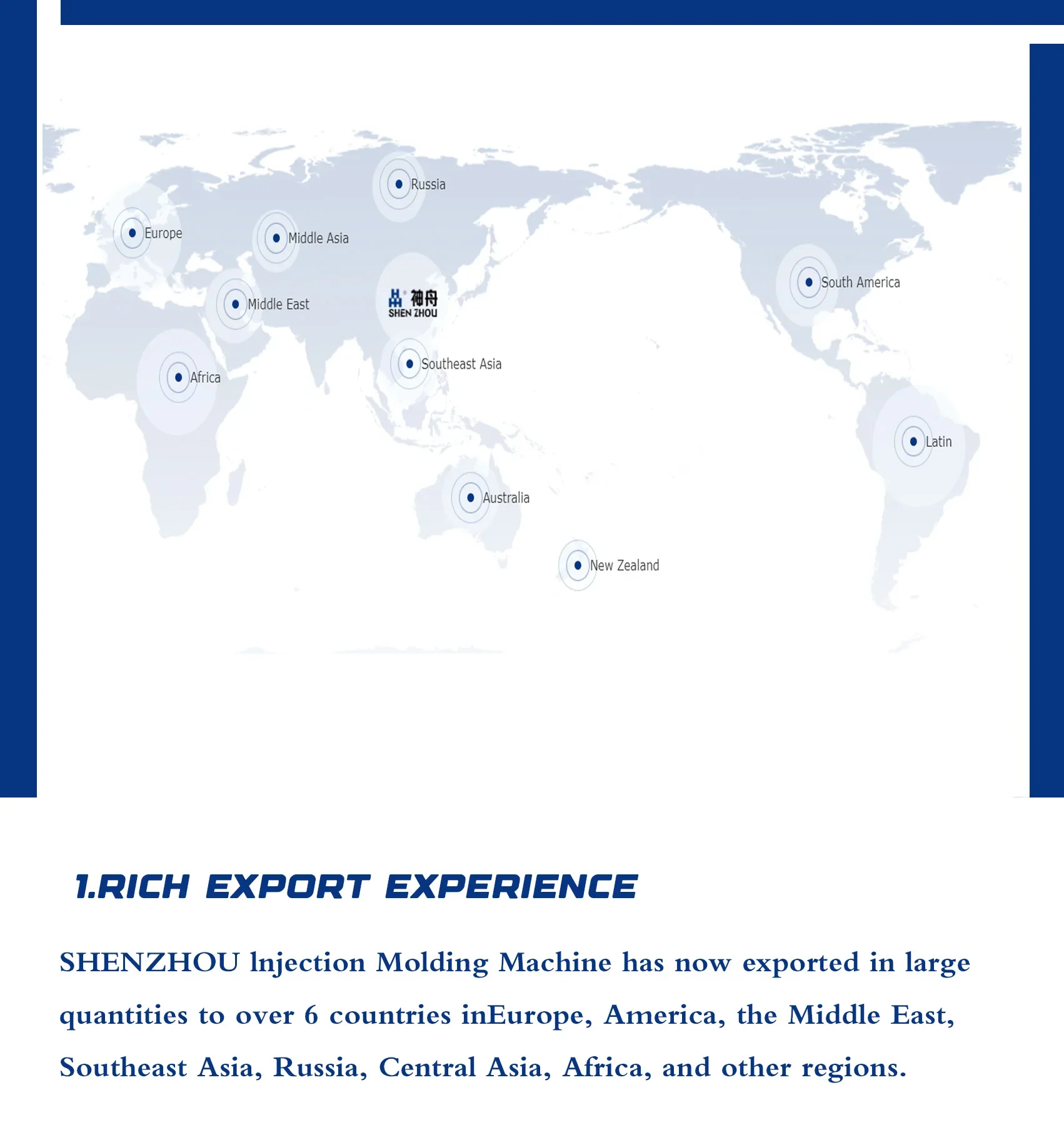

Company Information

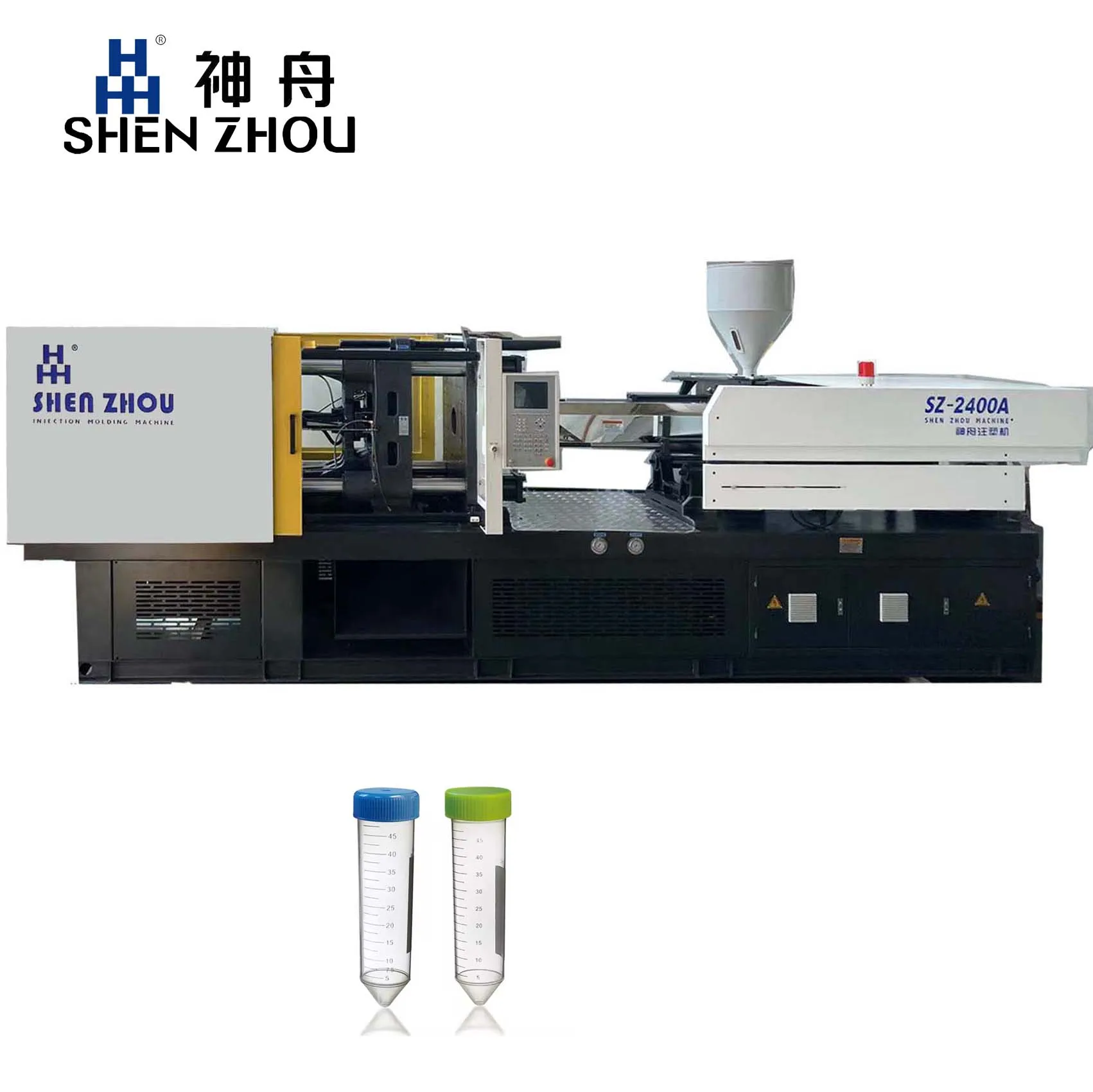

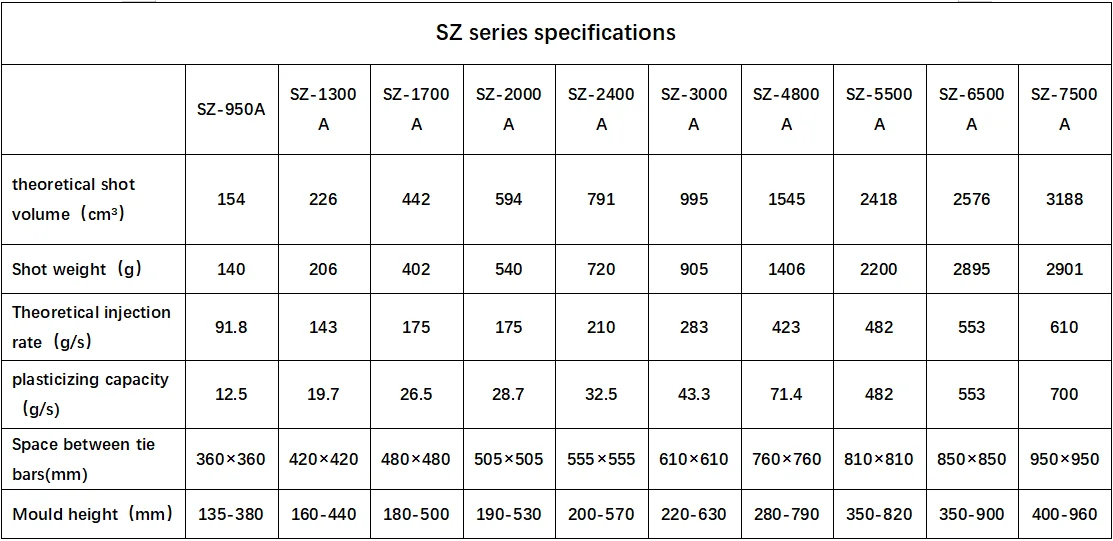

Technical Parameter

项目 ITEM |

单位UNIT |

SZ—2400A |

|||||||

注射装置 INJECTION UNIT |

|||||||||

螺杆直径 |

SCREW DIAMETER |

mm |

55 |

60 |

65 |

||||

螺杆长径比 |

SCREW LID RATIO |

L/D |

22.9 |

21 |

19.4 |

||||

理论注射容积 |

THEORETICAL SHOT VOLUME |

CM3 |

665 |

791 |

929 |

||||

注射质量(PS料) |

SHOT WEIGHT(PS) |

g |

605 |

720 |

845 |

||||

注射压力 |

INJECTION PRESSURE |

Mpa |

210 |

176 |

150 |

||||

理论注射速率(PS料) |

THEORETICAL INJECTION RATE(PS) |

g/s |

176.5 |

210 |

245 |

||||

塑化能力(PS料) |

PLASTICISING CAPACITY |

g/s |

26.4 |

32.5 |

40 |

||||

螺杆驱动扭矩 |

SCREW TORQUE |

N.m |

2000 |

||||||

螺杆最高转速 |

MAX.SCREW ROTATE SPEED |

r/min |

150 |

||||||

洼射行程 |

INJECTION STROKE |

mm |

280 |

||||||

合模装置 CLAMPING UNIT |

|||||||||

合模力 |

MAX.CLAMPING FORCE K |

KN |

2400 |

||||||

移模行程 |

MAX.OPENING STROKE |

mm |

530 |

||||||

拉杆有效间距(VxH) |

SPACE BETWEEN TIE BARS |

mm |

555×555 |

||||||

允许模厚(MIN-MAX) |

MOULD HEIGHT |

mm |

200-570 |

||||||

模板最大开距 |

MAX.DAYLIGHT |

mm |

1100 |

||||||

液压顶出力 |

EJECTOR FORCE |

KN |

61.5 |

||||||

液压顶出行程 |

EJECTOR STROKE |

mm |

135 |

||||||

液压顶出杆总数 |

EJECTOR QUANTITY |

9 |

|||||||

其它 OTHER |

|||||||||

油泵电动机功率 |

PUMP MOTOR POWER |

KW |

22 |

||||||

油泵最高压力 |

PUMP PRESSURE |

Mpa |

16 |

||||||

料简加热功率 |

HEATING POWER |

KW |

18.5 |

||||||

加热区段 |

HEATING ZONE |

5 |

|||||||

机器外形(LxWxH) |

SIZE |

m |

6.2×1.6×2.1 |

||||||

机器净重 |

NET WEIGHT |

t |

8.0 |

||||||

油箱容积 |

OIL TANK CAPACITY |

L |

440 |

||||||

国际公认型号 |

INTERNATIONAL DESIGNATION |

2400—1390 |

|||||||

Exhibition

FAQ

1.Q:Are you a factory or trading company? A: Industry and Trade Integration, we supply the factory price with good quality, welcome to visit ! 2.Q:How does your factory do regarding quality control? A:"Quality is priority. we always attach great importance to quality controlling from the very beginning to the very end and we have a dedicated quality control department. 3.Q:What are your normal lead times? A:Our company typical lead times range from 25-35days after receipt of order.We also have independent venues and engineers to deal with more urgent orders, which can be shipped within 2 weeks. 4.Q:About the price? A:We will estimate the cost and provide you with the best price. We can guarantee you the best product quality and after-sales service at the same price. Old customers will enjoy more price concessions. 5.Q:How is your machine different from other businesses? A:We have optimized the overall layout of each part of the machine to make the machine run smoothly and have a longer service life. The fine parts have exclusive marks, which makes it more convenient for customers to replace parts and use. 6.Q:Where is your factory located? How can I visit there? A: Our factory is located in Shenzhou Machinery, No. 22 Zhenbei Road, Fenghuang Town, Zhangjiagang City China. All our clients,from home or abroad, are warmly welcome to visit us!

You are welcome to send us samples, we will customize high-quality machines for you! Best wishes for you!