Address

#1062 Zhenbei Road, Xizhang, Fenghuang Town, Zhangjiagang City, Jiangsu, China

| ITEM | UNIT | SZ—1300A | ||

| INJECTION UNIT | ||||

| SCREW DIAMETER | mm | 35 | 40 | 45 |

| SCREW LID RATIO | L/D | 24 | 21 | 18.7 |

| THEORETICAL SHOT VOLUME | CM3 | 173 | 226 | 286 |

| SHOT WEIGHT(PS) | g | 158 | 206 | 260 |

| INJECTION PRESSURE | Mpa | 235 | 180 | 142 |

| THEORETICAL INJECTION RATE(PS) | g/s | 110 | 143 | 181 |

| PLASTICISING CAPACITY | g/s | 13.8 | 19.7 | 27.1 |

| SCREW TORQUE | N.m | 740 | ||

| MAX.SCREW ROTATE SPEED | r/min | 250 | ||

| INJECTION STROKE | mm | 180 | ||

| CLAMPING UNIT | ||||

| MAX.CLAMPING FORCE K | KN | 1300 | ||

| MAX.OPENING STROKE | mm | 400 | ||

| SPACE BETWEEN TIE BARS | mm | 420×420 | ||

| MOULD HEIGHT | mm | 160-440 | ||

| MAX.DAYLIGHT | mm | 840 | ||

| EJECTOR FORCE | KN | 31.4 | ||

| EJECTOR STROKE | mm | 100 | ||

| EJECTOR QUANTITY | 5 | |||

| OTHER | ||||

| PUMP MOTOR POWER | KW | 13 | ||

| PUMP PRESSURE | Mpa | 16 | ||

| HEATING POWER | KW | 9.2 | ||

| HEATING ZONE | 4 | |||

| SIZE | m | 4.7×1.25×1.85 | ||

| NET WEIGHT | t | 4.3 | ||

| OIL TANK CAPACITY | L | 360 | ||

| INTERNATIONAL DESIGNATION | 1300—410 | |||

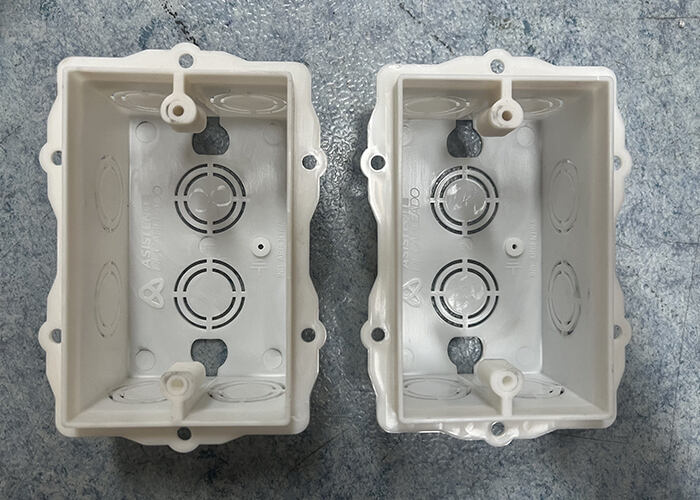

According to the requirements of the usage environment (such as waterproofing, flame retardancy, and heat resistance), different materials should be selected.

PVC (polyvinyl chloride): High cost performance, good insulation, suitable for indoor dry environments (such as household circuit wiring).

ABS resin: Strong impact resistance, smooth surface, often used in industrial equipment or scenarios requiring frequent disassembly.

PC (polycarbonate): Resistant to high temperatures (-40℃ to 120℃), UV resistant, suitable for outdoor or high-temperature environments (such as street lamp wiring).

PP (polypropylene): Resistant to chemical corrosion, suitable for humid or acidic and alkaline places (such as laboratories, chemical workshops).

Based on the product drawings (dimensions, hole positions, sealing grooves, etc.), a 3D mold model is designed using CAD software to ensure accuracy (tolerance within ±0.05mm) and avoid gaps during assembly.

Injection molding production: The mixed plastic pellets are heated and melted (temperature 160-250℃, depending on the material), and then injected into the mold cavity under high pressure by an injection molding machine. After cooling and solidifying, the mold is removed to form components such as box bodies and box covers.

Post-processing: Remove flash and burrs. Some products require drilling (for reserved wire holes), installing sealing rings (to enhance water resistance), or printing labels (such as specifications and protection levels).

#1062 Zhenbei Road, Xizhang, Fenghuang Town, Zhangjiagang City, Jiangsu, China