Description

The quality of bottle blowing molds can be evaluated from multiple aspects, and the following are some key considerations:

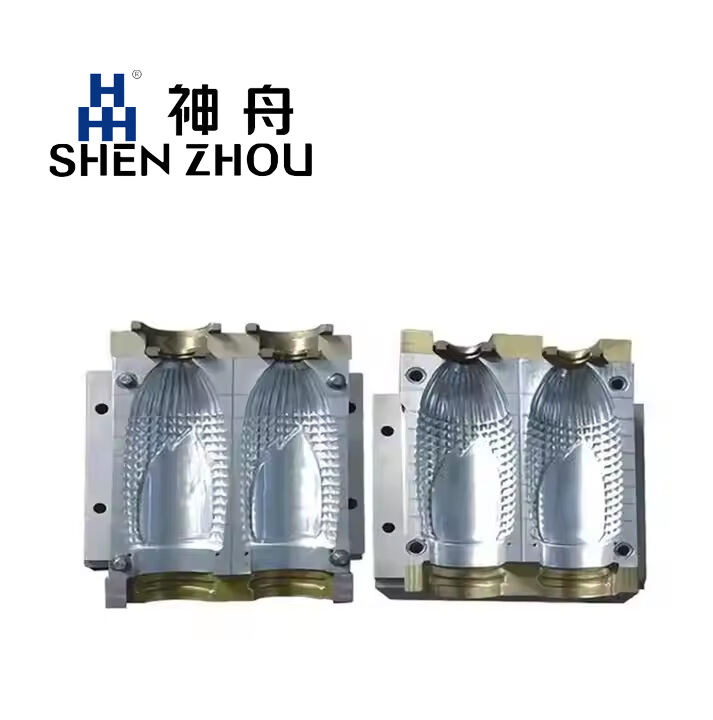

Mold material

High quality materials: Good blow molding molds usually use high-quality mold steel, such as P20 steel, H13 steel, etc. These steels have high hardness, high strength, good wear resistance and corrosion resistance, and can withstand high pressure, high temperature and friction during the blowing process, ensuring the service life of the mold. For example, H13 steel has good toughness and thermal fatigue performance, making it suitable for producing high-yield blow molding molds.

Poor quality materials: Molds made of inferior steel are prone to wear, deformation, cracks, and other problems, which shorten the service life of the mold and increase production costs. Moreover, inferior materials may lead to a decrease in the accuracy of the mold, affecting the quality of bottle molding.

Machining accuracy

High precision: Excellent blow molding molds have high processing accuracy, which can ensure the dimensional accuracy and appearance quality of bottles. The dimensional accuracy of the mold cavity is usually controlled within ± 0.01mm, and the surface roughness reaches Ra0.8-Ra1.6 μ m. High precision molds can make the wall thickness of the bottle uniform, the size of the bottle mouth, bottleneck and other parts accurate, and improve the sealing and stability of the bottle.

Low precision: Molds with low processing precision can result in large bottle size deviations, uneven wall thickness, and unattractive appearance. For example, inaccurate bottle mouth size may cause the bottle cap to fail to seal properly, affecting the quality and shelf life of the product.

Design rationality

Reasonable design: A good blow molding mold design should fully consider the flow characteristics of plastic, the structural characteristics of the bottle, and the requirements of the blow molding process. For example, a reasonable design of the position and quantity of the sprue can evenly fill the mold cavity with plastic, avoiding defects such as weld lines and bubbles. At the same time, the demolding mechanism of the mold should be designed reasonably to facilitate the smooth demolding of the bottle and reduce scratches and deformation on the surface of the bottle.

-Unreasonable design: Unreasonable mold design can lead to various problems in the production process, such as insufficient plastic filling, bottle deformation, and difficult demolding. These issues not only affect production efficiency, but also increase scrap rates and raise production costs.